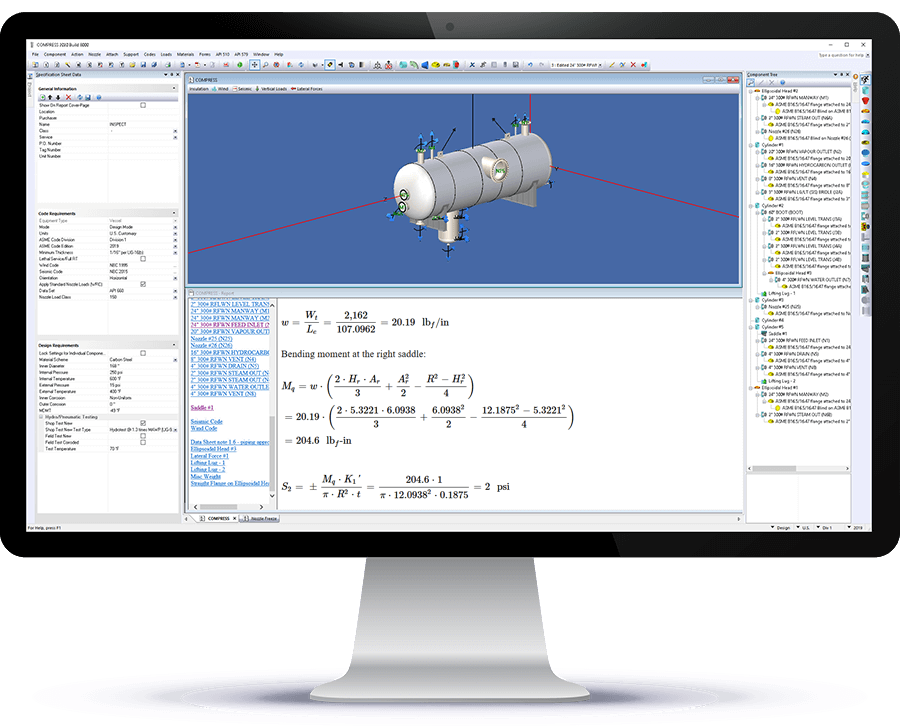

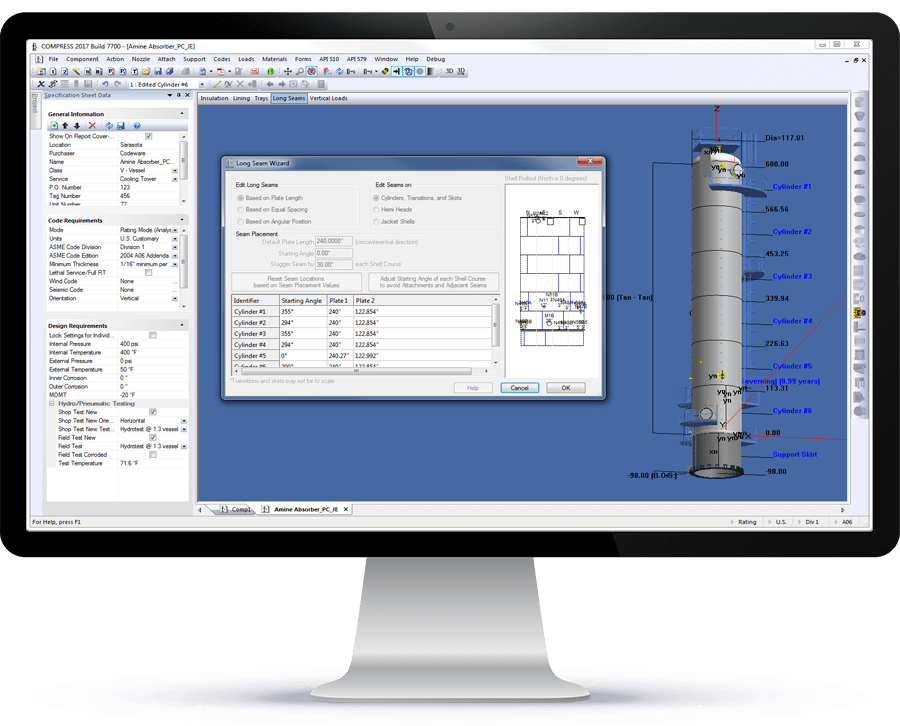

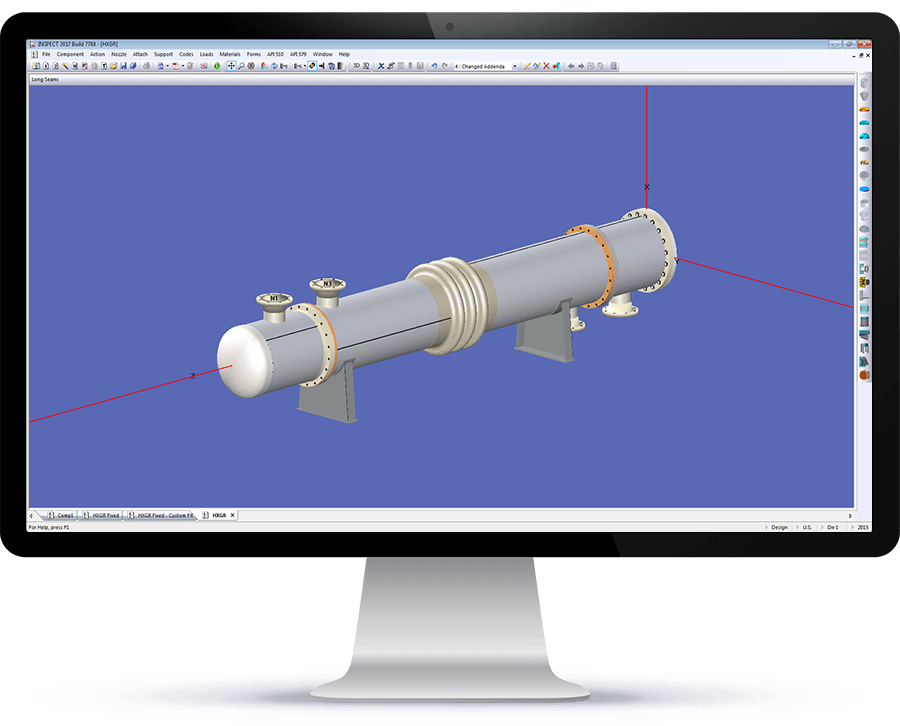

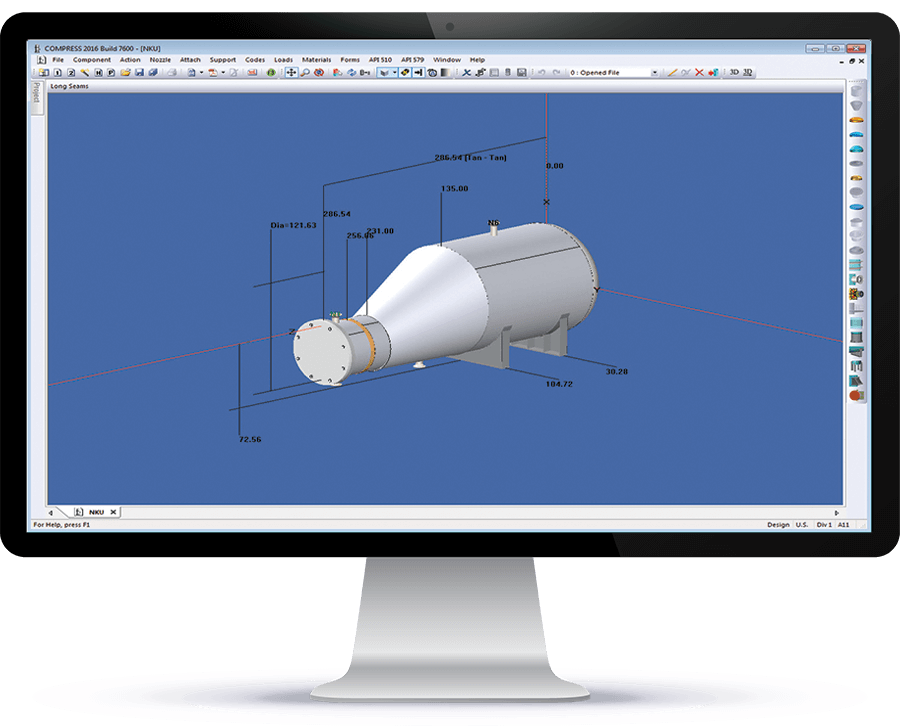

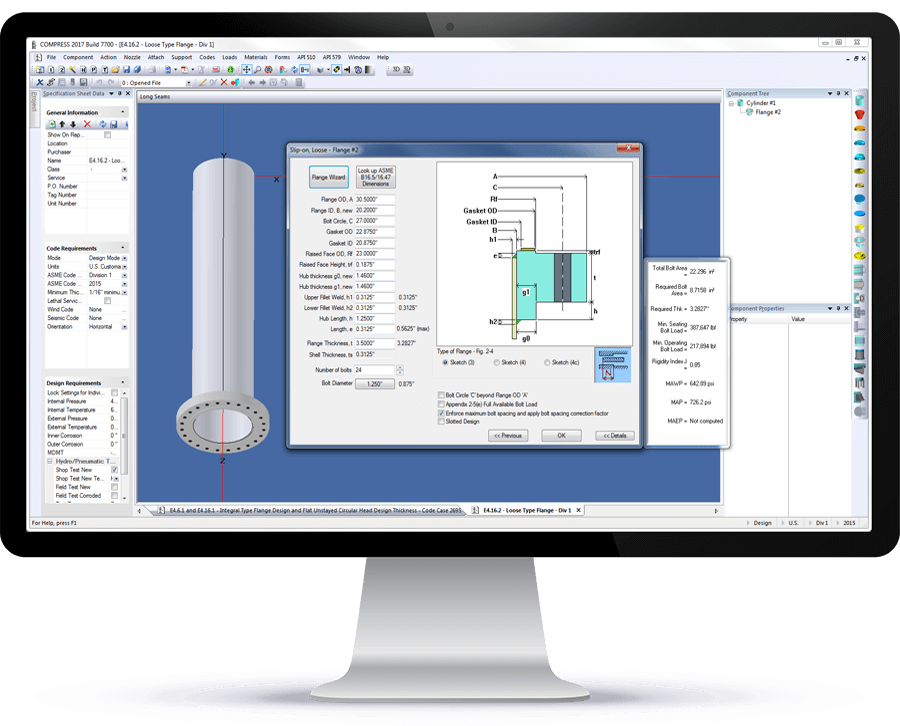

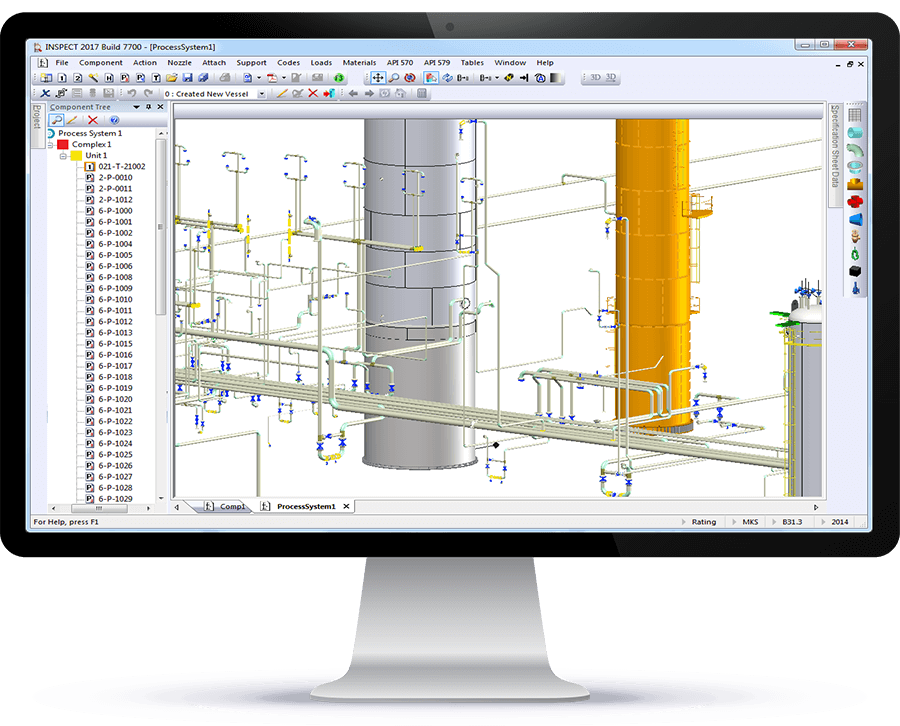

Quote, design and fabricate faster and smarter with the leading ASME pressure vessel software. COMPRESS saves Engineering hours, prevents mistakes, and helps shorten equipment delivery times. It combines comprehensive ASME® calculations with cost estimating, solid modeling, and automatic drawing generation.

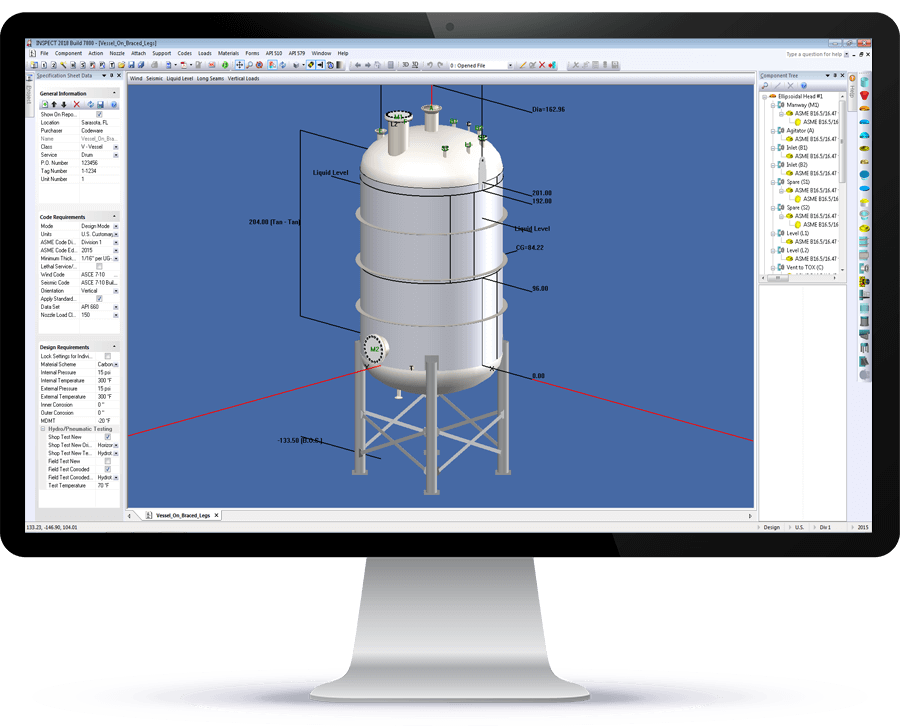

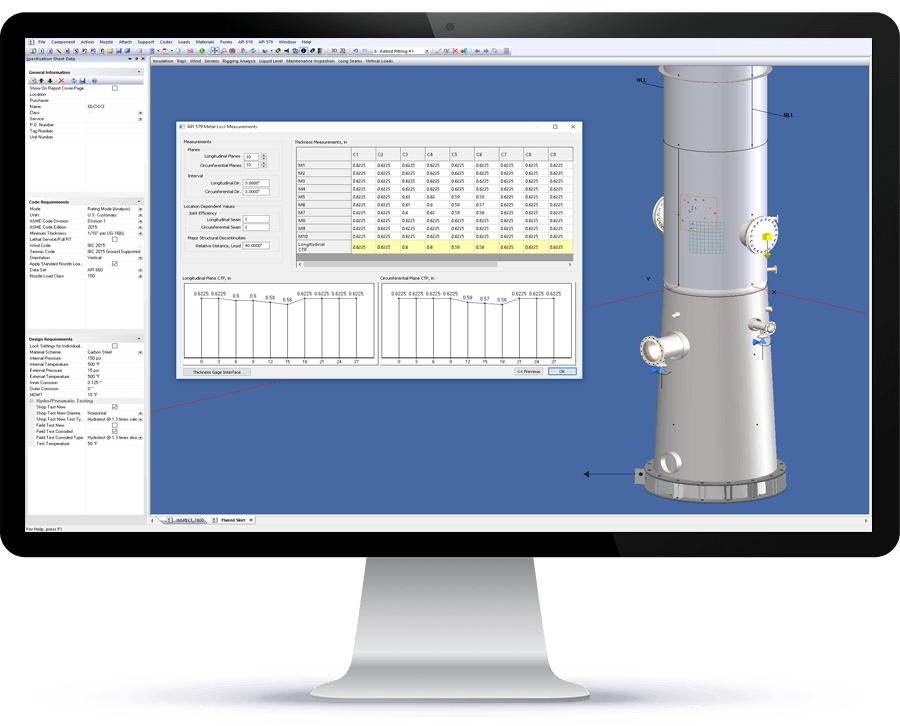

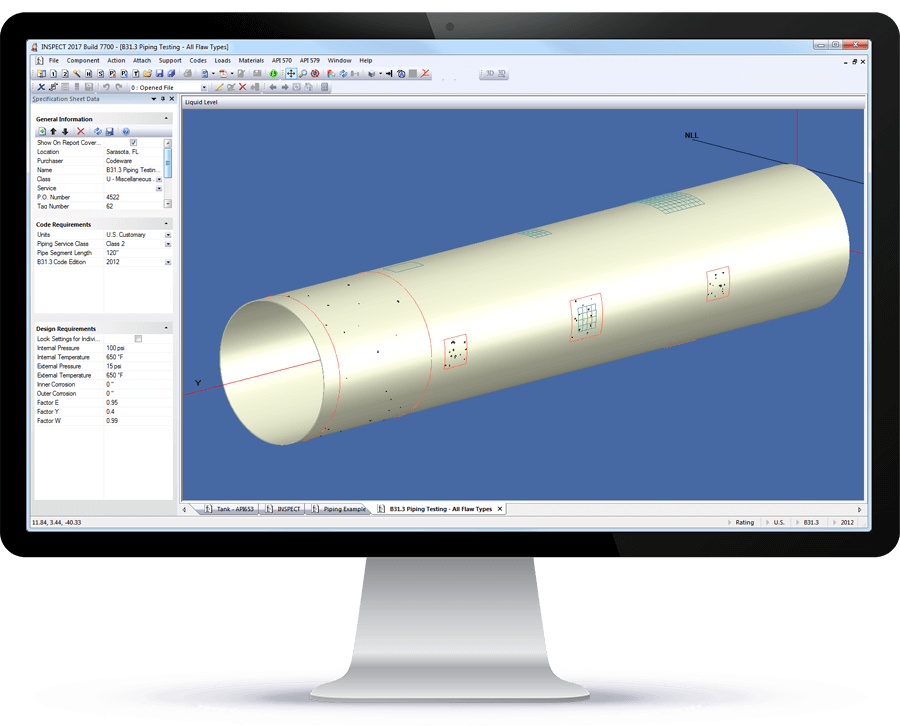

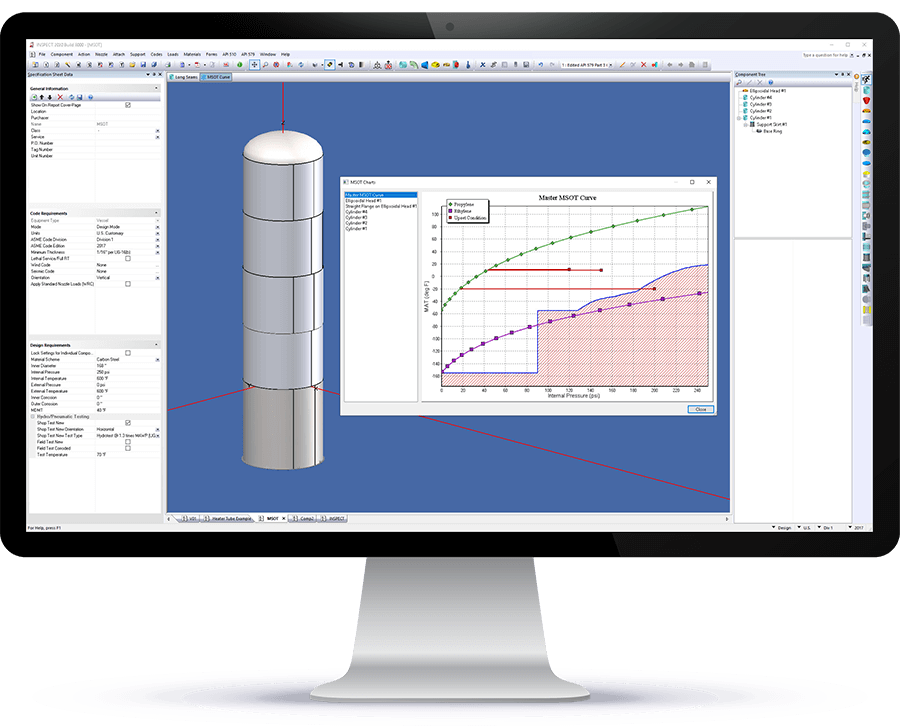

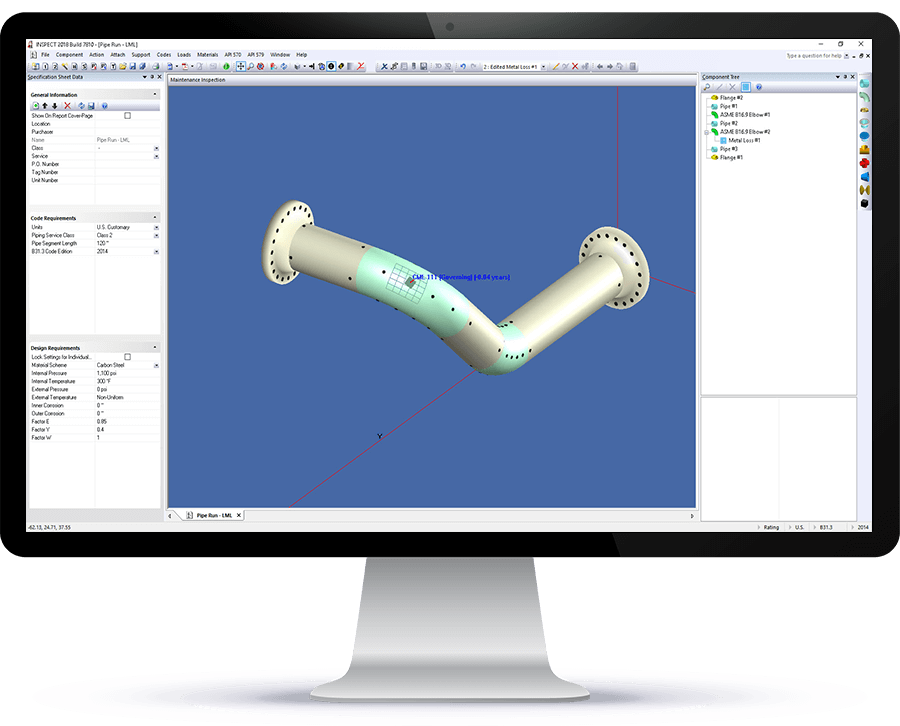

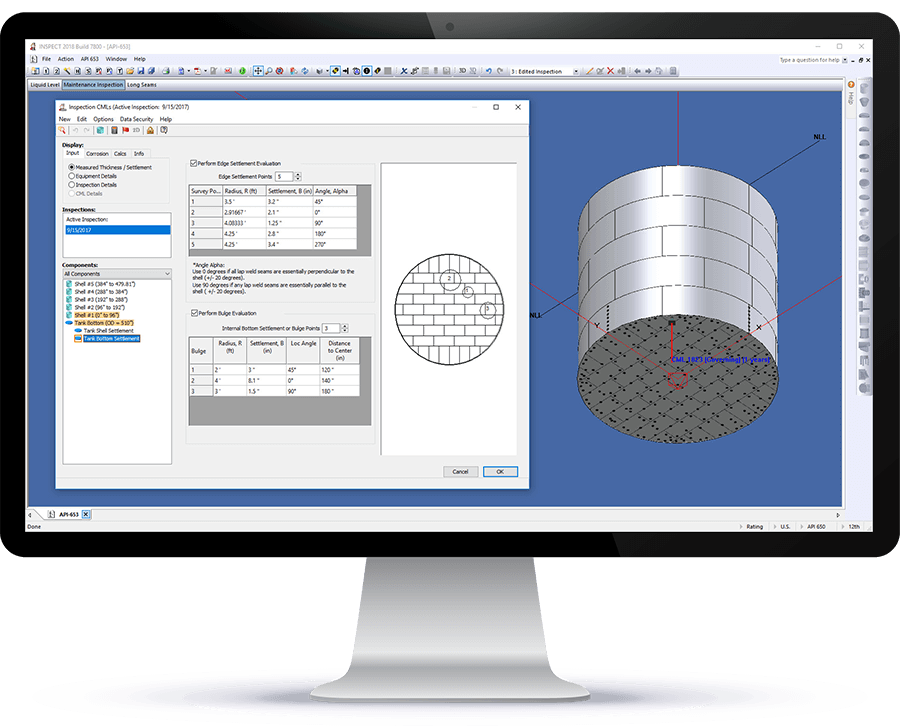

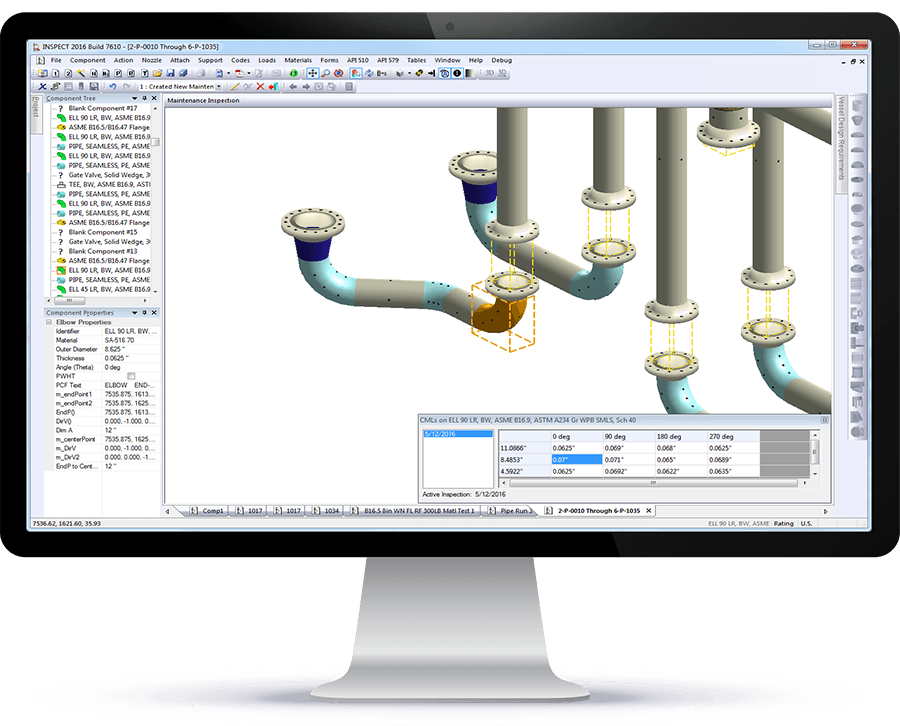

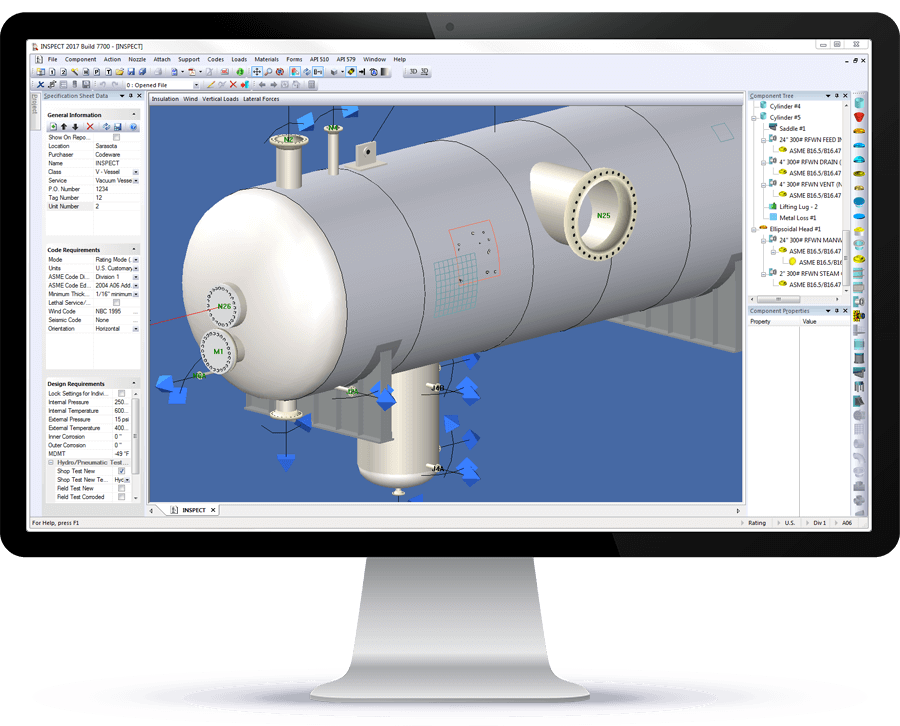

INSPECT is a combined Fitness-For-Service and 3D Inspection Data Management System that determines equipment remaining life and inspection schedules. INSPECT provides the FFS calculations and documentation needed by your Fixed Equipment Mechanical Integrity Program. INSPECT’s reports reduce regulatory risk by documenting undocumented pressure vessels and showing API compliance for piping and above ground storage tanks.

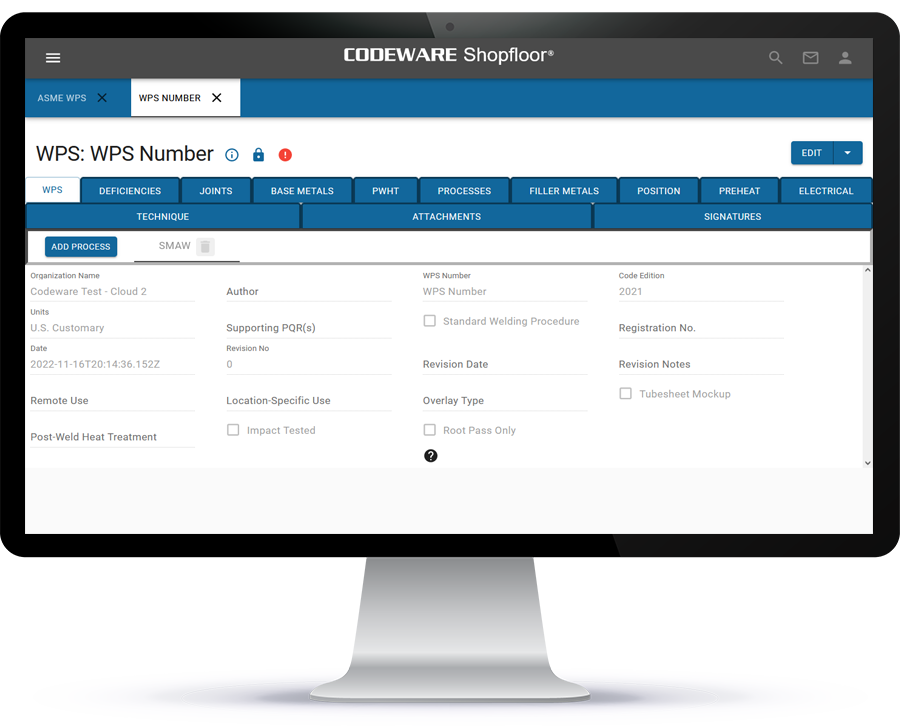

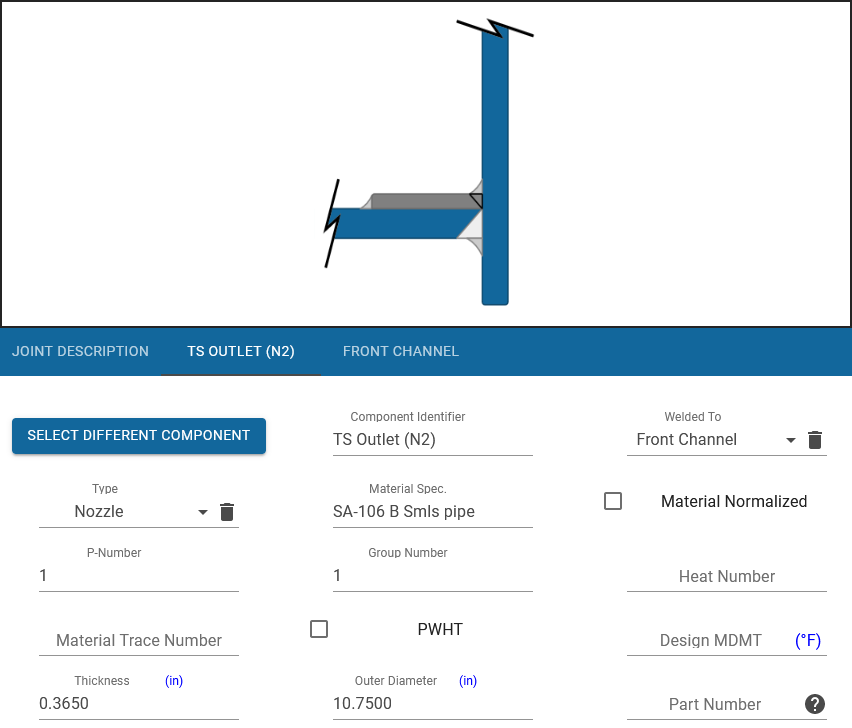

Shopfloor simplifies welding management and helps fabricators avoid auditor “gotchas”. It features integration with COMPRESS created pressure vessels and heat exchangers as well. The sharing of WPS information between Shopfloor and COMPRESS results in time savings and fewer errors. Shopfloor is a web based welding documentation software application that allows unlimited user access while providing the latest in data management, access, and security.

Contact Codeware