ASME Interpretation BPV VIII-1-16-85:

Nozzle Loads and ASME B16.5 and B16.47 Flange Ratings

OK, here is the new Interpretation that addresses loadings on your standard flanges….if this is the first time hearing about this don’t worry I’m going to break this down.

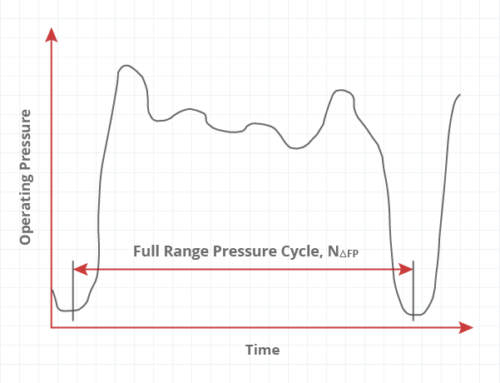

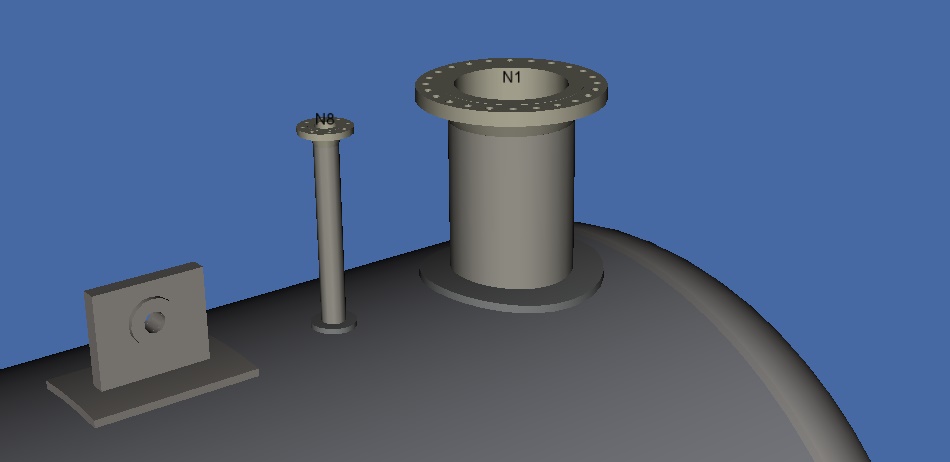

In 2017 the ASME released Code Interpretation BPV VIII-1-16-85. Essentially this interpretation states that if you have external loadings acting on a nozzle you have to consider them on the flange too. This has long been a requirement of the UG-22 loadings rules, so it is nothing new. Seems reasonable right? But why is it after all these years and after countless standard ASME B16.5 /B16.47 flanges have been used successfully, it is this now being enforced? Great question, let’s discuss. All of what I am saying is, of course, my own personal opinion.

As we all know a flange failure is typically going to be in the form of leakage. So while we (fortunately) don’t have explosions flanged joints may be releasing emissions (sometimes dangerous) into the environment. This to me is why this interpretation came out. Now let’s have a look at those standard flanges. They have been around for years and years. “Let’s order quantity X of weld necks because they are good to a certain pressure/temperature” is usually what most purchasing departments will do. Here’s where I think the issue is with them.

So how do we consider these external loads on our flanges? In COMPRESS we implemented a method years ago to address this. We take the loads and calculate an equivalent pressure and knock it off the flange pressure rating. Great, done, let’s move on. Not so fast. The issue you will run into is most standard flanges will receive a large reduction in their rated pressure. I think there needs to be more research done on this but for the time being we better get prepared to jump up class sizes. (Editor’s note: Since this blog was first published the ASME has added provisions in UG-44 to address this issue. Starting with COMPRESS 2020, support for the flange loading provisions of UG-44 is included in COMPRESS.)

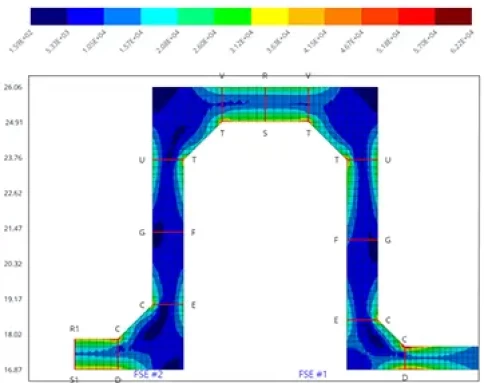

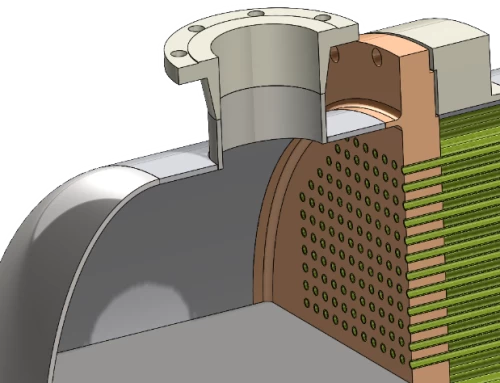

So what do we do now? Well thankfully the ASME Code has a great little section called Appendix 2. The Appendix 2 rules are a far more rigorous analysis that accounts for the ‘m’ and ‘y’ factors of the actual gasket you have and can consider the flange loadings. Some jurisdictions are even requiring all Standard B16.5/16.47 flanges be run through an Appendix 2 analysis. I personally have no problem with this. If you are using COMPRESS we provide a flange wizard to help you with your design. We can look up standard flange geometries or optimize the gasket location, number and size of bolts in order to get the most economical design for you.

So there you have it. An interpretation break down in a nutshell. Fortunately if you are using COMPRESS you will be covered.

Code Case 2901 provides an analysis for evaluating external loads on standard B16.5/B16.47 weld neck flanges.

See how to activate this analysis in COMPRESS