Cree dibujos automáticamente con el Interfaz Codeware®.

La interfaz Codeware (CWI) ahorra tiempo a los diseñadores y reduce los errores al generar rápidamente modelos sólidos de recipientes a presión de SOLIDWORKS® o Inventor® a partir de diseños de COMPRESS e INSPECT. También incluye Drafter 3D, una función que genera dibujos de recipientes a presión a partir de modelos sólidos creados por CWI. El CWI está disponible como complemento para SOLIDWORKS o Inventor y se suministra sin coste adicional para los clientes de Codeware. Gestiona los datos asociados a los archivos de diseño importados mediante el uso de iProperties (Inventor) o Custom Properties (SOLIDWORKS). El CWI también admite el uso de técnicas avanzadas de modelado de sólidos, como representaciones de ensamblaje, configuraciones, características, bocetos, chapas metálicas y Mates.

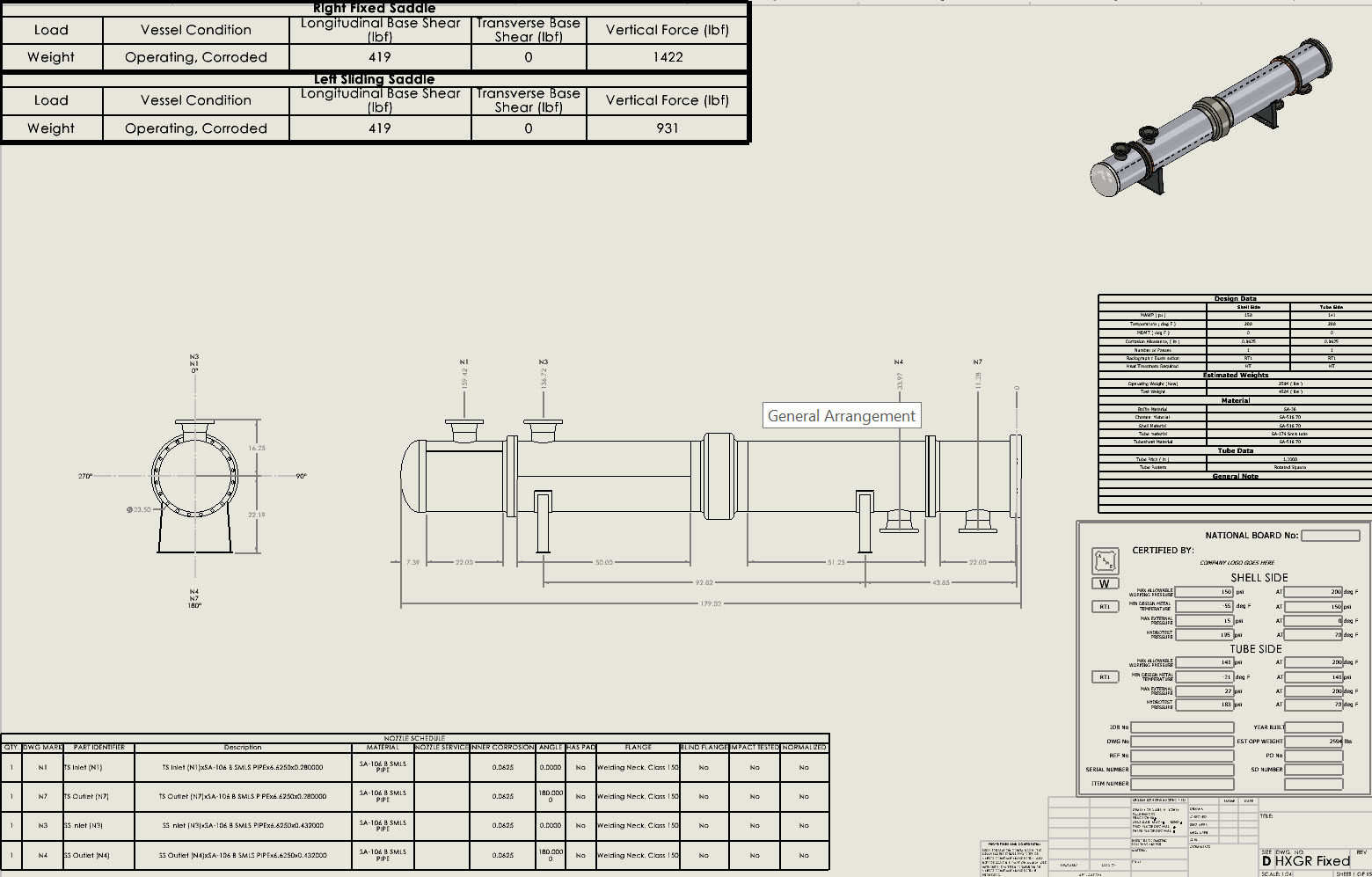

COMPRESS → Dibujos

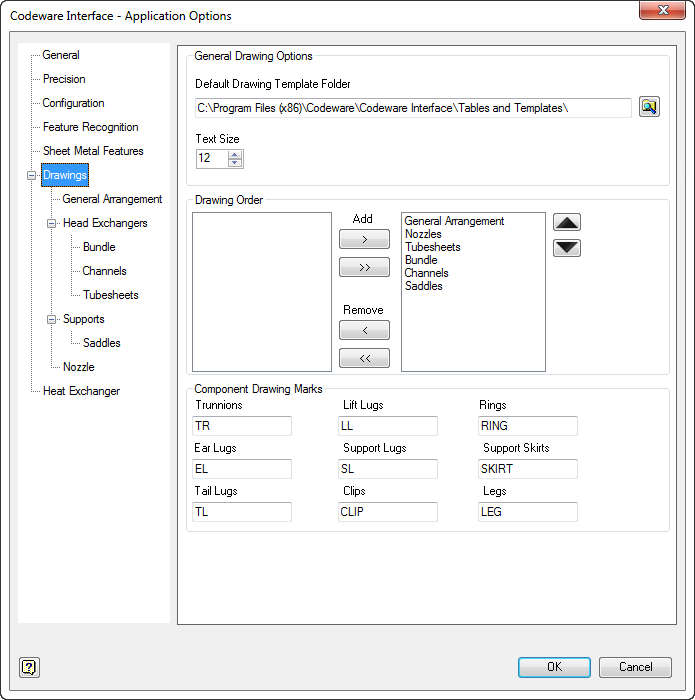

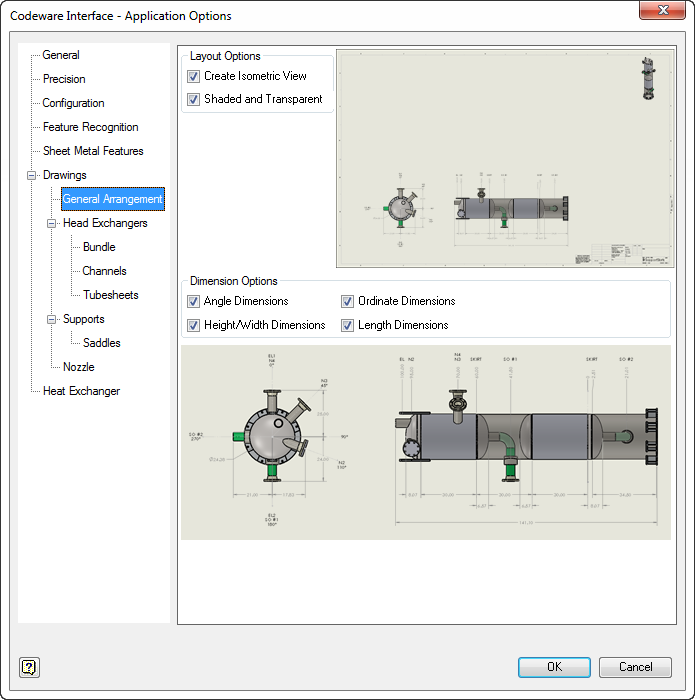

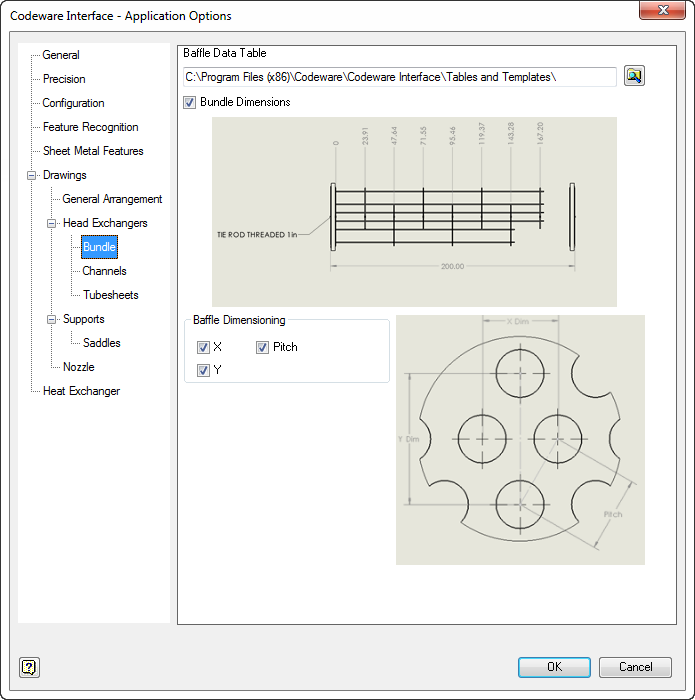

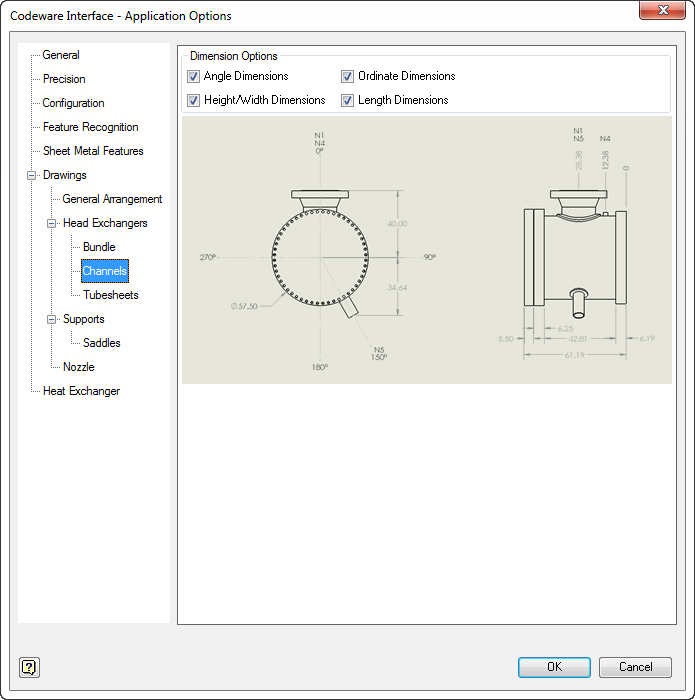

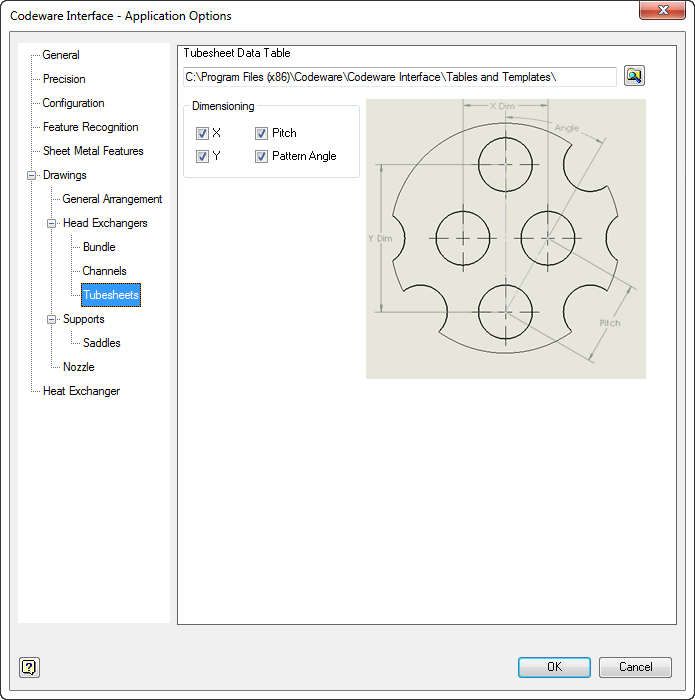

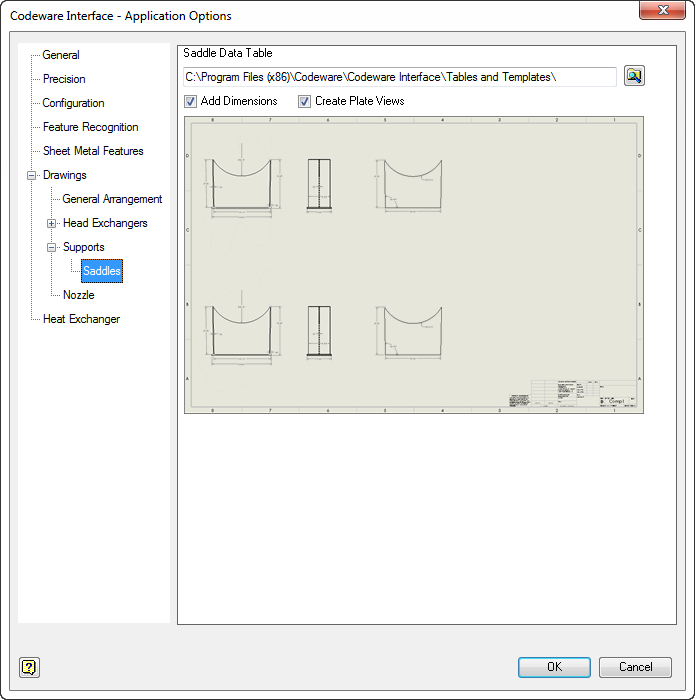

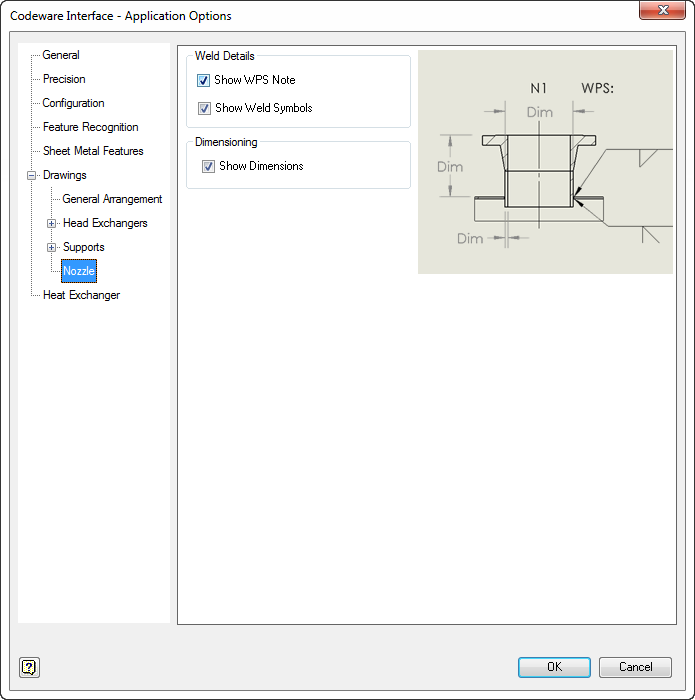

Opciones de dibujo de la interfaz de Codeware

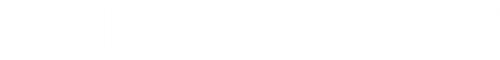

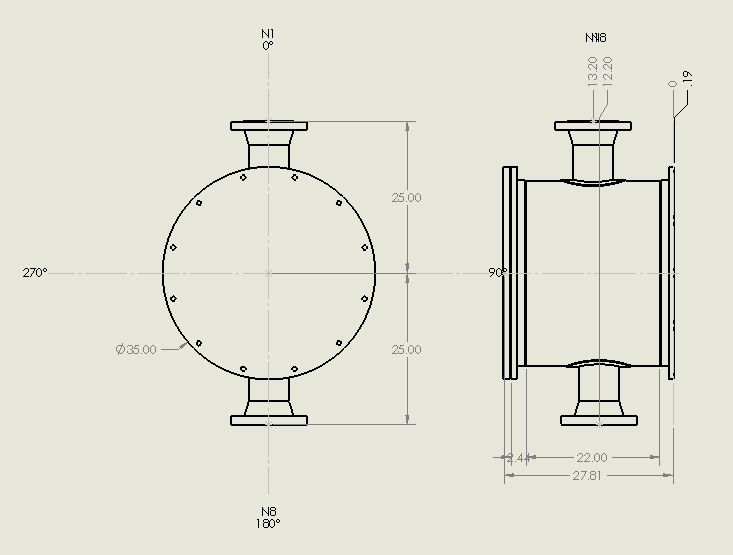

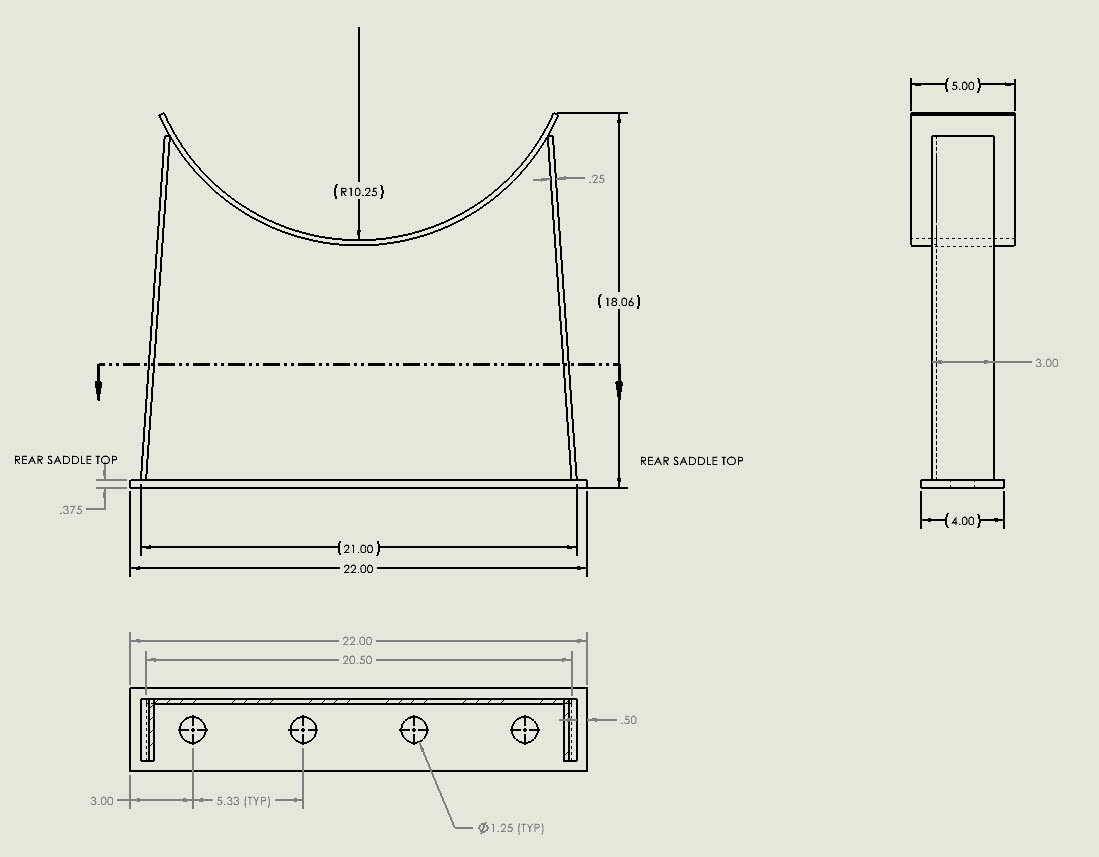

Cree y personalice eficazmente las vistas frontal, lateral e isométrica de sus embarcaciones. Las vistas frontal y lateral incluyen el ángulo de fijación, la ordenada, la longitud junto con las dimensiones de altura/anchura.

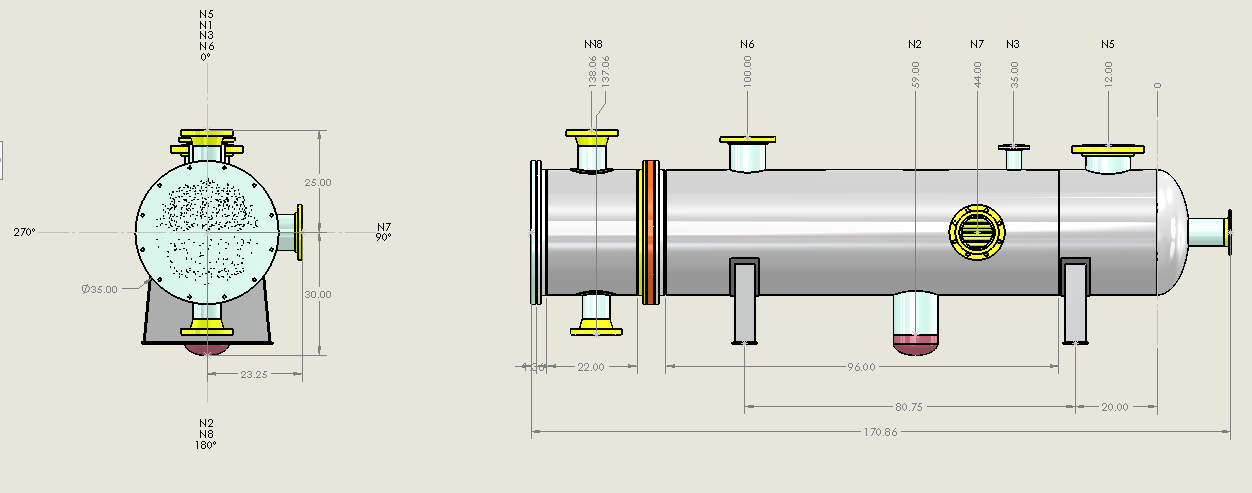

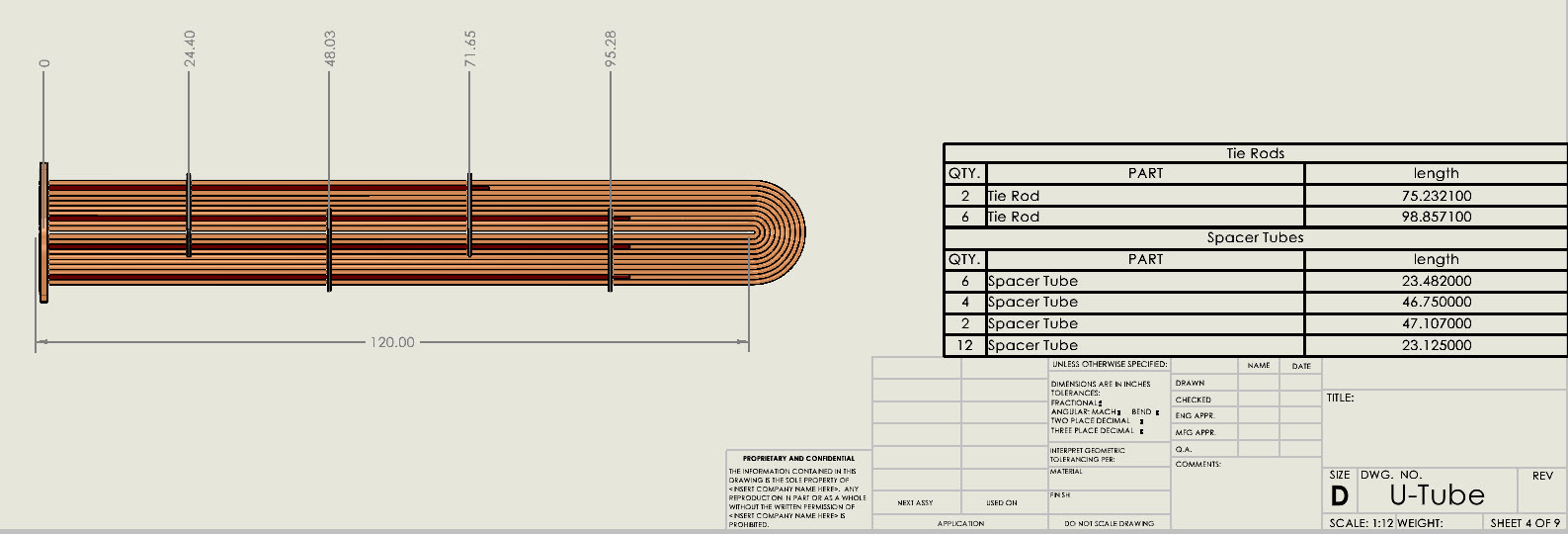

Los planos de intercambiadores de calor personalizables incluyen haces, canales y placas tubulares. La altura, la anchura, el grosor y las dimensiones de la disposición de los tubos están disponibles para su aplicación automática.

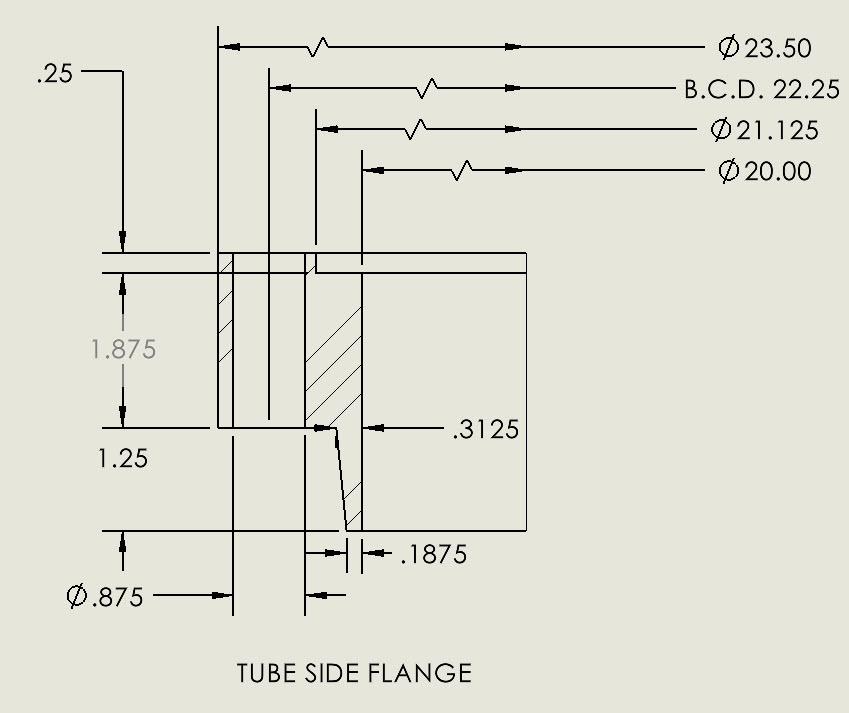

Los dibujos de detalle de las bridas personalizadas incluyen automáticamente el identificador del componente y las dimensiones.

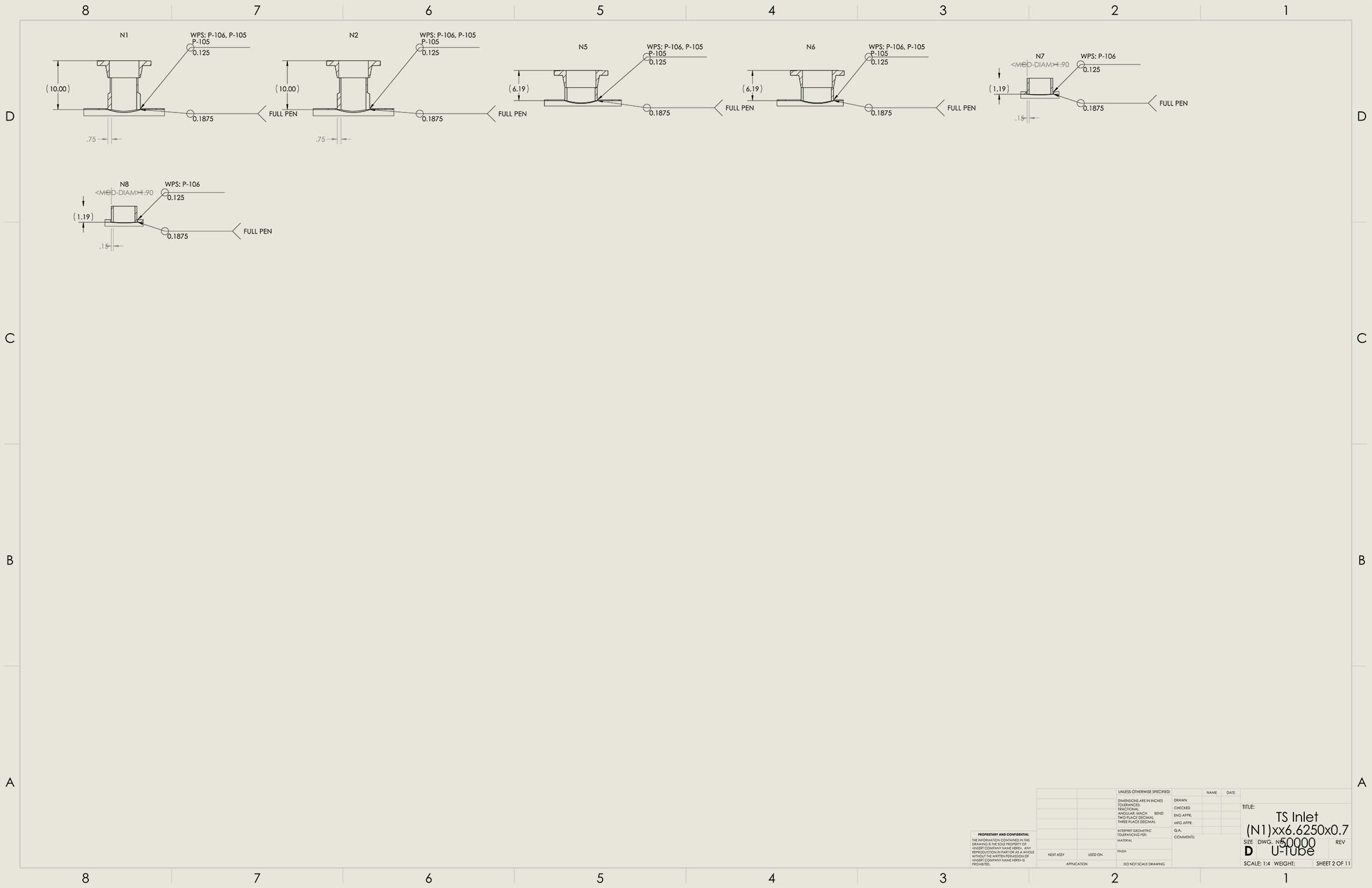

Los dibujos de detalle de las boquillas incluyen automáticamente notas WPS, símbolos de soldadura y dimensiones.

+1 (941) 927-2670 | sales@codeware.com