COMPRESS Improves Engineering Productivity

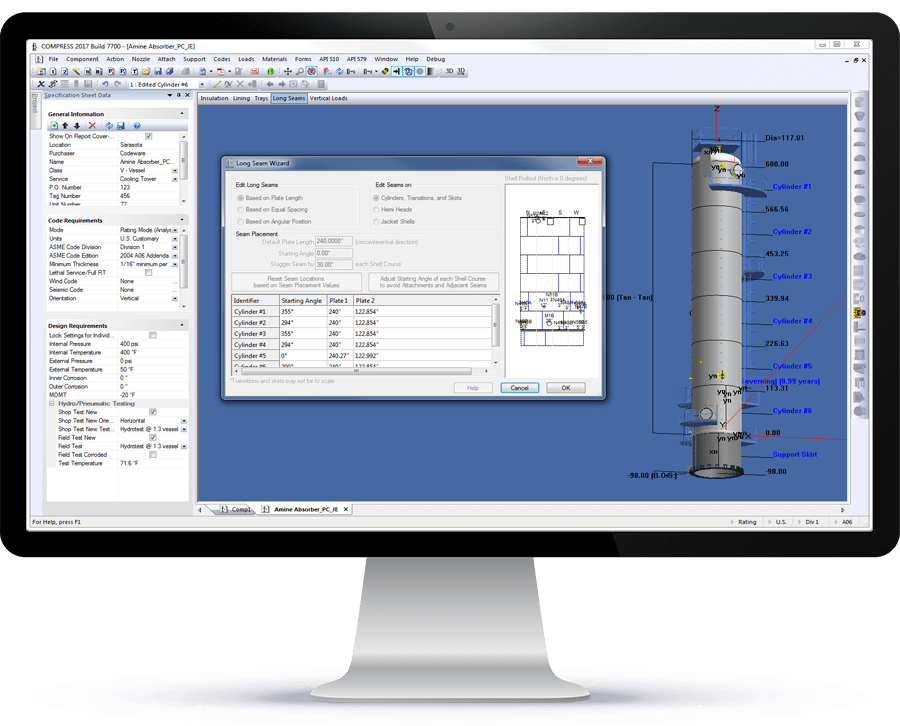

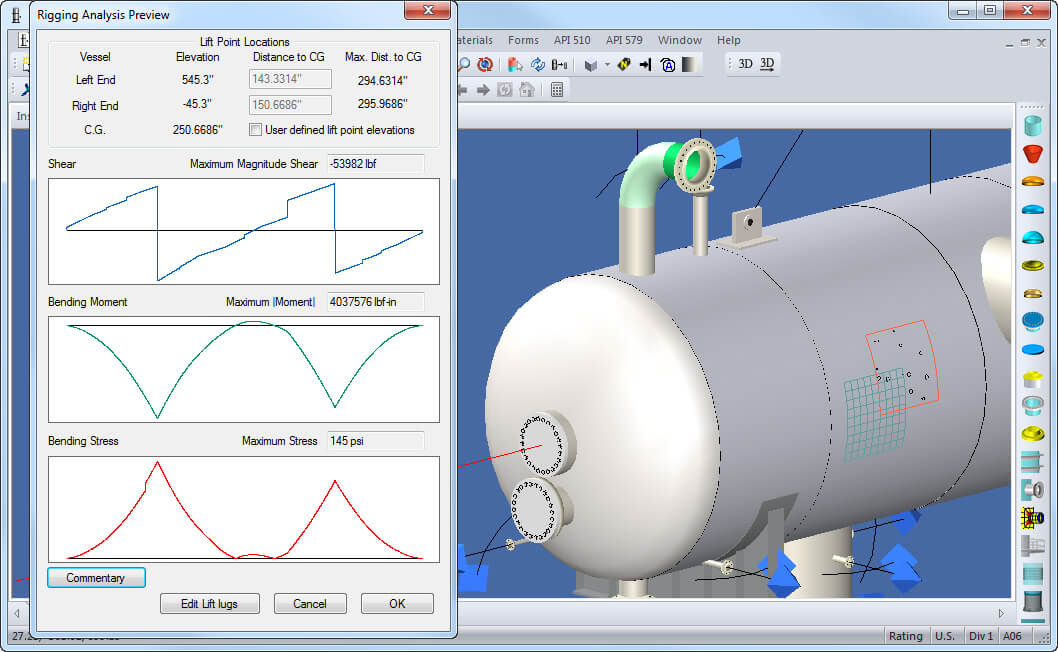

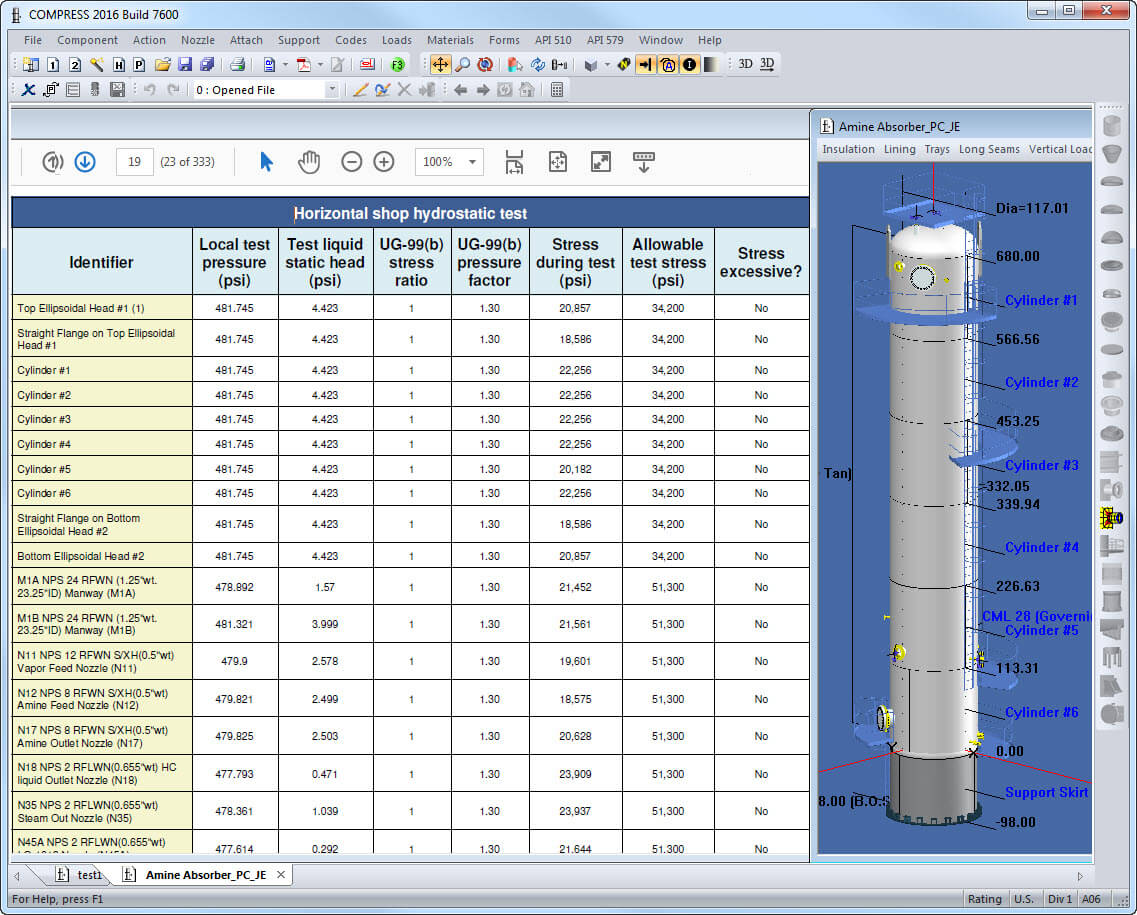

Experienced Vessel Engineers are always in short supply. COMPRESS makes the most of their valuable time by performing calculations that competing products do not offer. It also speeds equipment model creation with features such as nozzle copy and paste and the COMPRESS Vessel Wizard. Unlike other software that provide analysis only, COMPRESS offers both Rating (analysis) and Design Modes. In Design Mode, COMPRESS takes your input data and selects component sizes and thicknesses automatically all based on ASME Code requirements.

Large projects can span several years and new projects are always contracted using the latest ASME Code. COMPRESS easily handles this situation by supporting multiple Code Editions. This saves on IT costs and avoids having to keep track of multiple vessel programs, one for each ASME Code year.

COMPRESS Prevents Mistakes

The ASME Code is a complex set of mandatory rules subject to regular updates. An Engineer specializing in the Code must be familiar, and stay current with, a wide range of technical subjects. Building Codes, related Codes and Standards, good engineering practices, customer specifications not to mention advances in computing make this a challenging area of Engineering practice. COMPRESS has been in widespread use for over 30 years and helps Engineers navigate through this and avoid Code related errors and omissions.

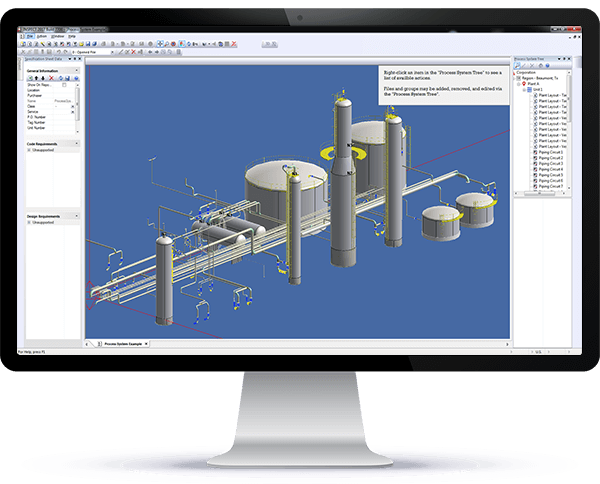

A COMPRESS designed tall tower being installed.

Note the strut used to prevent damage to the support skirt.

Photo Credit: Ken Grakauskas of New Century Engineering & Design