Perform API 570 In-Service Piping Evaluations With INSPECT

The API 570 Piping Inspection Code is a widely used document that describes the minimum requirements and guidelines for maintaining the integrity of piping systems after they have been placed into service. INSPECT features 3D inspection data management and calculations that simplify compliance with the mechanical integrity requirements of API 570.

INSPECT’s API 570 Implementation

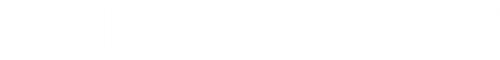

Includes a simple to use interface that speeds pipe model creation.

Can load pipe models directly from any software that exports .pcf files including ISOGEN® and AutoCAD®.

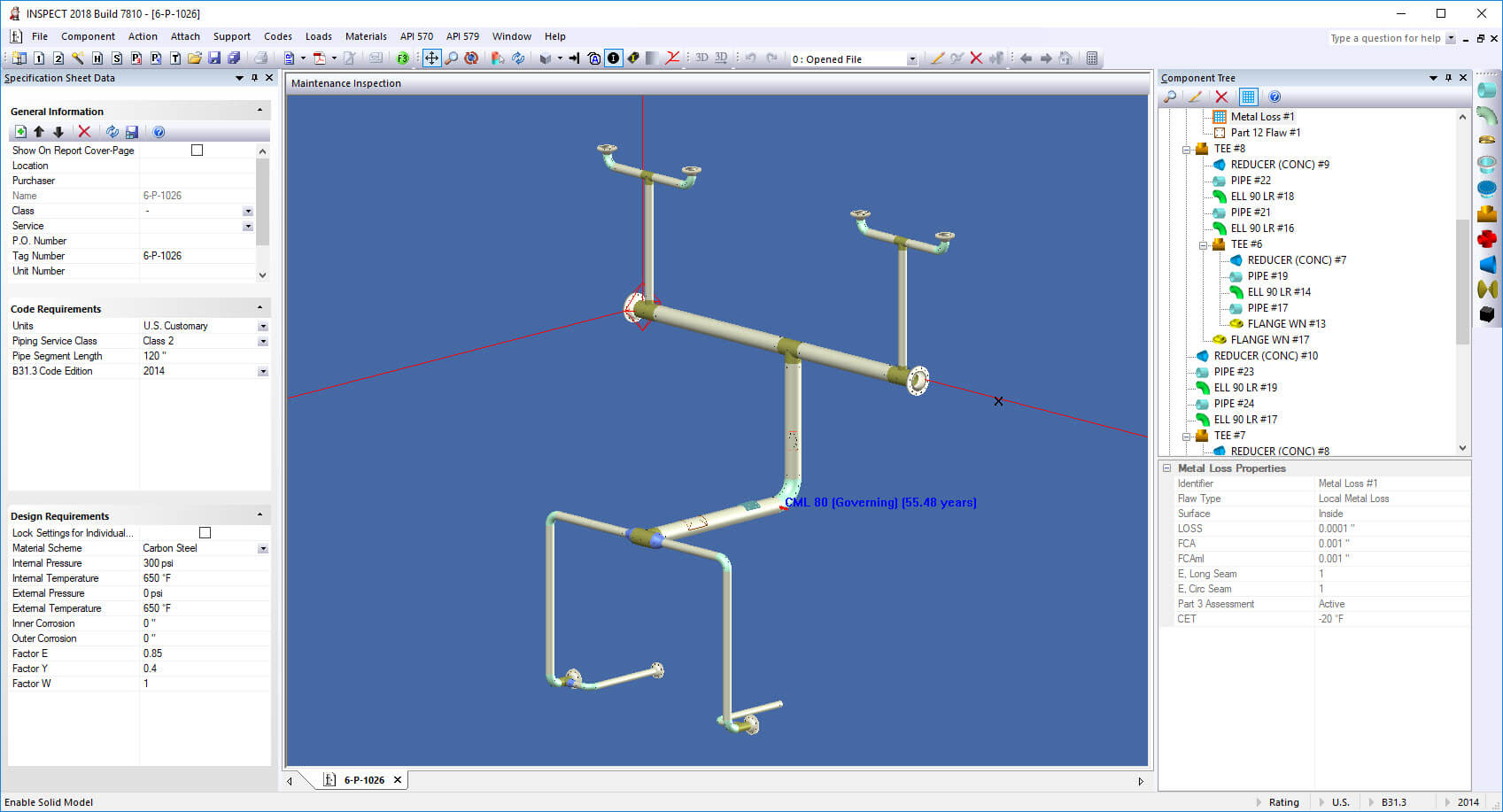

Provides automatic or manual CML (condition monitoring location) placement on pipes and elbows. Inspection locations and flaws are shown on the pipe model in 3D.

Flaw locations can also be displayed in Google Earth by clicking on the GPS coordinates in the corresponding flaw report.

Manages thickness survey measurements and includes data logger (thickness gage) integration.

Performs API 579-1 FFS assessments, as allowed by API 570, on a wide variety of flaws.

Produces API 570 pipe tmin calculations compliant with ASME B16.3 and B16.4.

Features built-in, fully user customizable API 570 checklists.

Determines remaining life times and inspection intervals.

API 579 Fitness-for-Service Piping Assessments with INSPECT

Increase Your Capabilities With INSPECT

Find Out More

+1 (941) 927-2670 | sales@codeware.com