Code Checks During WPS Creation Using Shopfloor

Code Checks During WPS Creation Using Shopfloor

Quality control is the bedrock of any good manufacturing process. Industry Codes, such as ASME IX and the American Welding Society (AWS), provide guidelines for achieving safety, cost, and operational benefits within a fabrication shop. By ensuring welding procedures comply with Code requirements, Shopfloor helps companies deliver high-quality equipment on time.

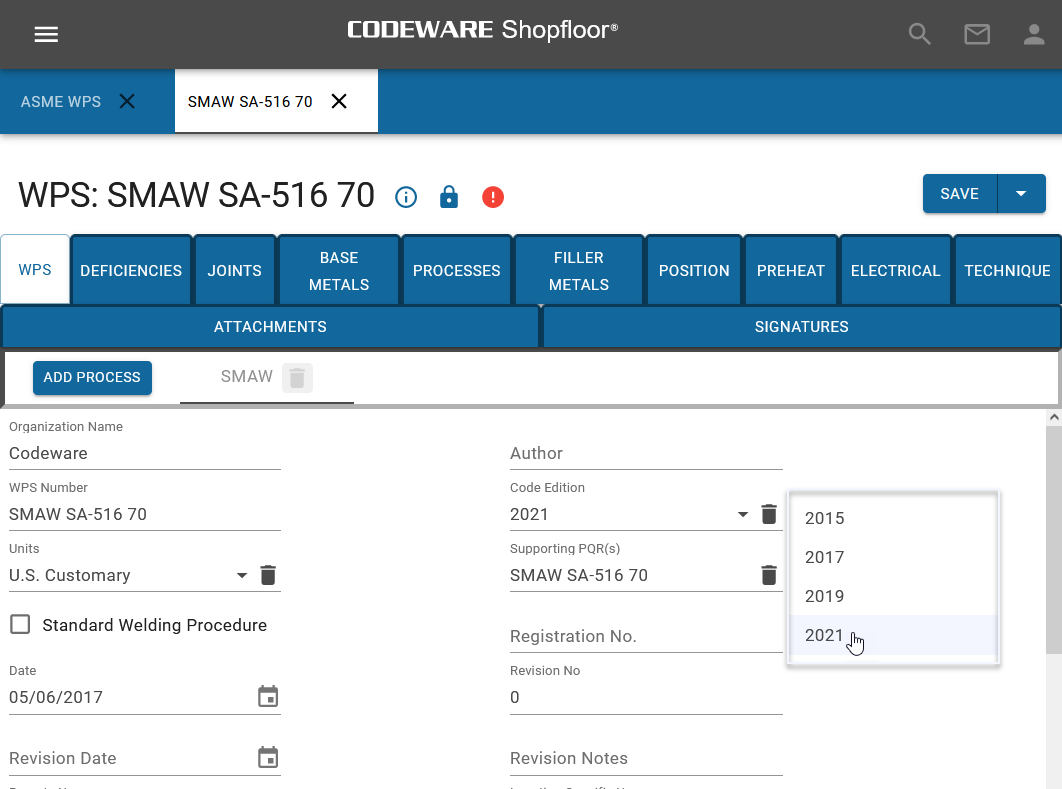

Shopfloor performs rigorous ASME IX and AWS Code checks as welding forms are created. Multiple Code Editions are supported so QC personnel are able to quickly validate and update legacy welding records to comply with the latest Code rules.

Essential and Supplementary Essential Variables in Shopfloor

Essential and Supplementary Essential Variables in Shopfloor

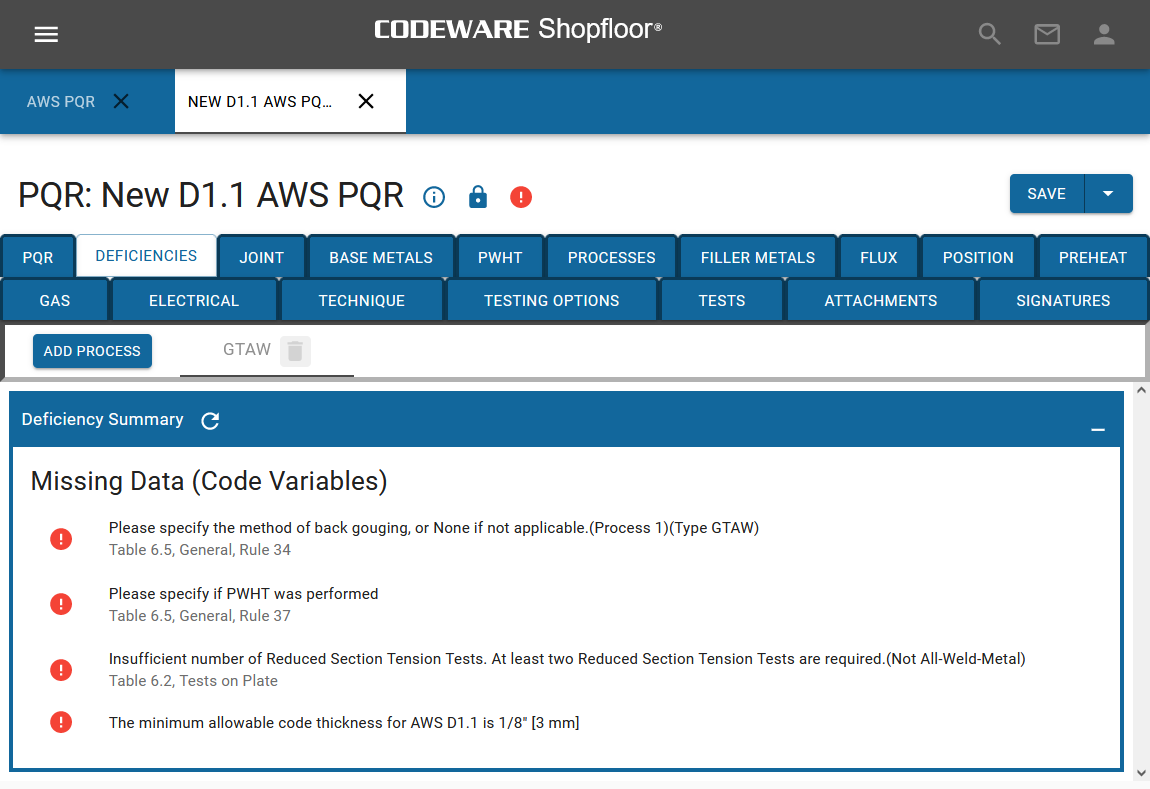

Shopfloor helps ensure Code compliance by pointing out missing Essential or Supplementary Essential Variables. Code deficiencies detected are reported with references to specific Code paragraphs for further review. Having Code checks built-in helps prevent the information “silos” that are sometimes encountered within QC departments. They also serve as an important training resource for new employees and provide Code reminders for experienced staff.

As a cloud-based application, Shopfloor can also be used as a repository for managing digital copies of manuals, work instructions, and other job related documents.

Code Checks Help Streamline WPS Generation

Code Checks Help Streamline WPS Generation

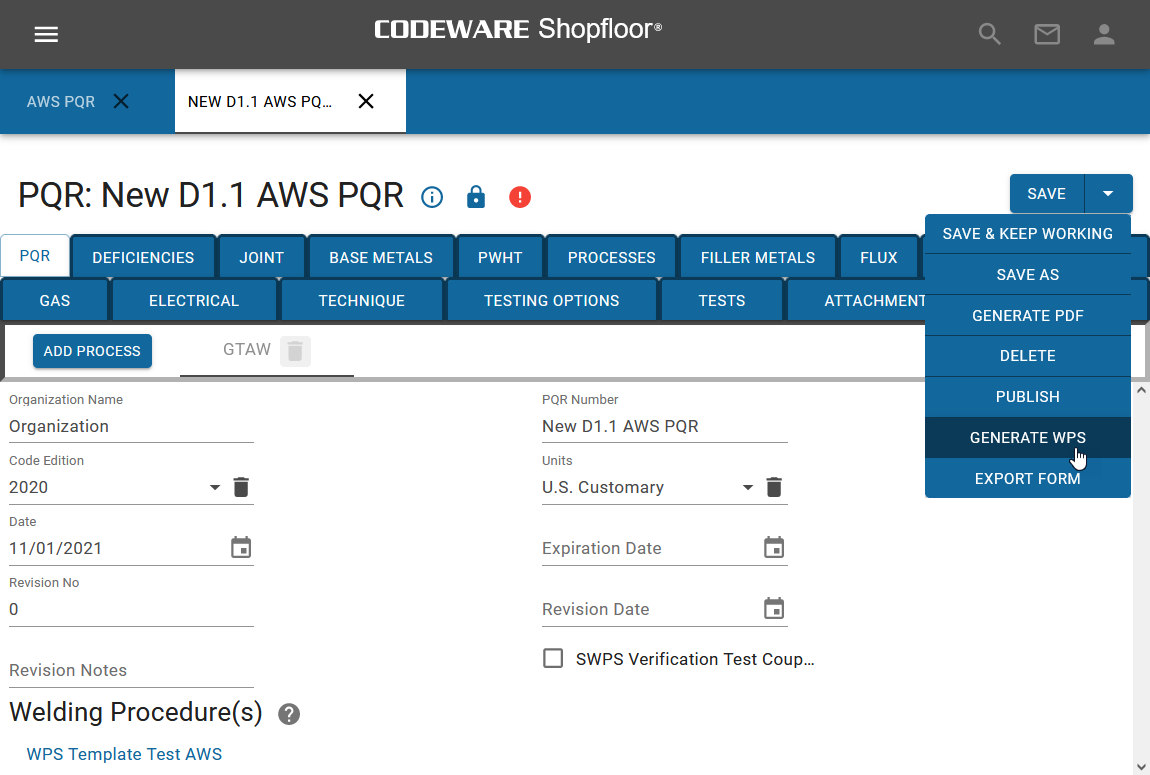

Shopfloor simplifies WPS generation by using data from existing PQR’s when generating welding procedures. It automatically determines qualified base metal materials and thickness ranges from the referenced PQR. This feature enhances productivity and helps prevent the costly mistake of duplicating and then re-qualifying existing welding procedures.

Shopfloor can also save time and reduce errors by loading COMPRESS pressure vessel design files. In this case Shopfloor will match the welds as specified in the COMPRESS design file with existing WPS’s. Welds that have no matching WPS are presented in a convenient list for further action.