INSPECT Reduces Risk

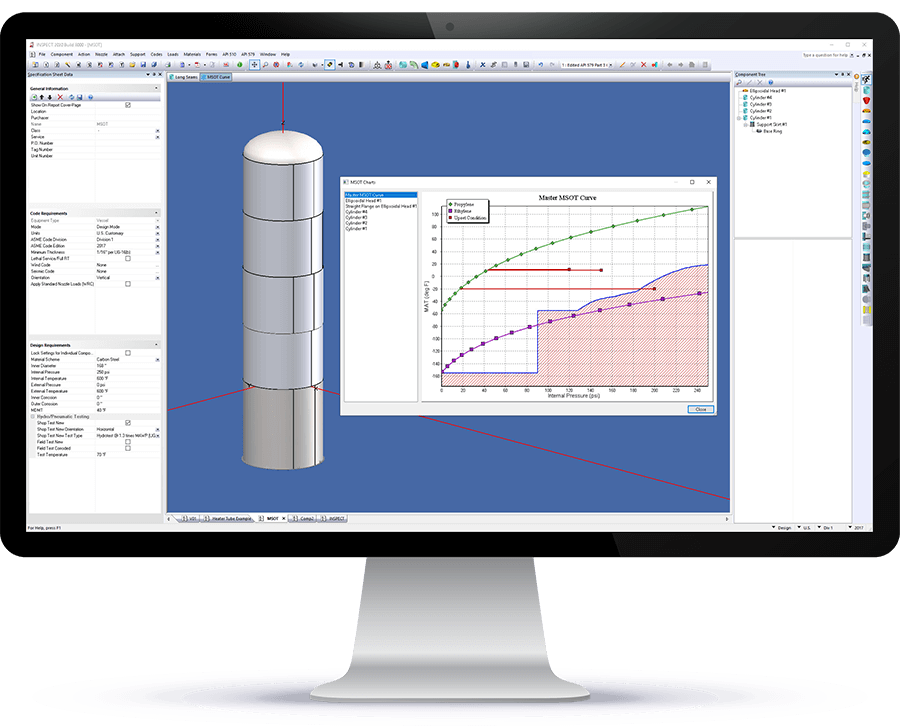

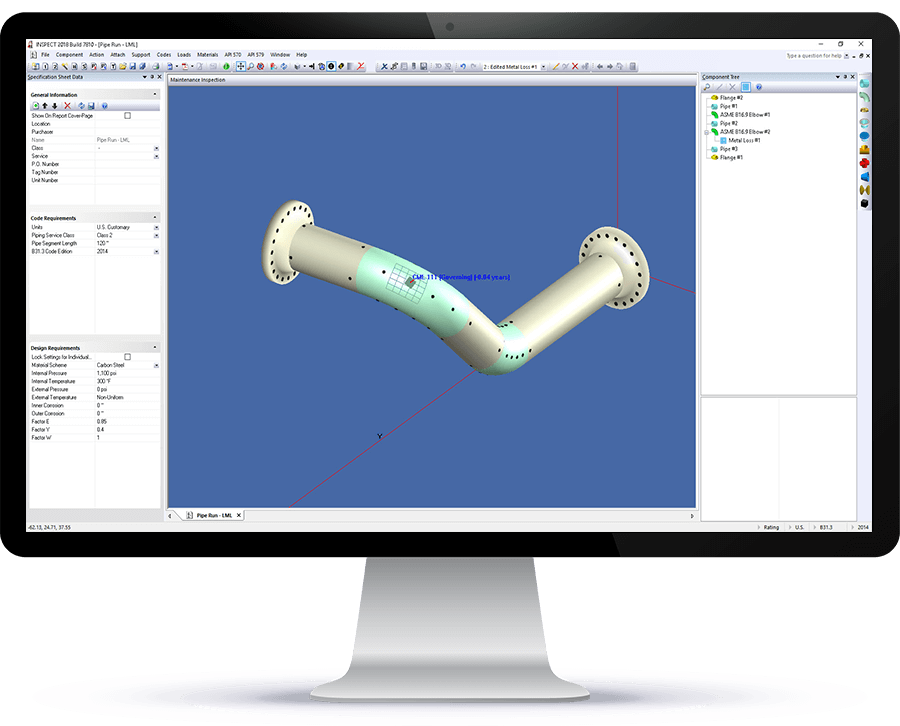

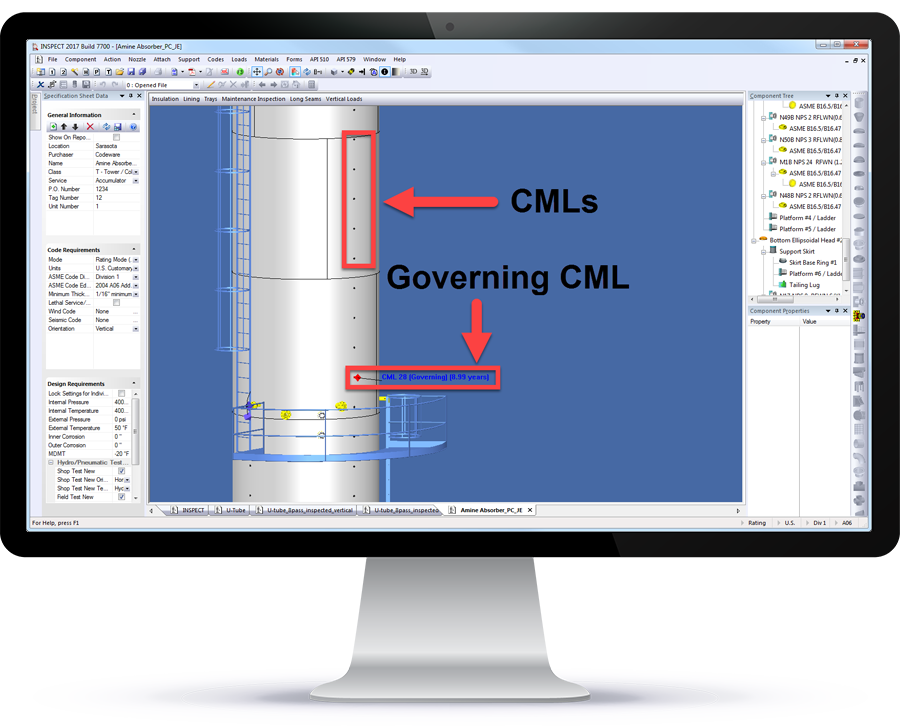

Shutdown inspections often find previously undetected damage and production needs to know if the equipment can be put back into service as soon as possible. INSPECT helps avoid mistakes in these circumstances by providing Engineers with a number of unique features. INSPECT’s 3D graphics provide visual confirmation that the equipment and the damage have been input correctly. INSPECT’s detailed reports allow Engineers to verify the supporting calculations for themselves. The easy to use and yet rigorous fitness-for-service analysis performed by INSPECT reduces the risk of making the wrong decision while keeping things on schedule.

INSPECT: Mechanical Integrity Software That Reduces Costs

INSPECT’s mechanical integrity and fitness-for-service tools help Engineers determine if it is safe to continue operating damaged piping and vessels and avoid un-planned shut-downs. They can also perform ASME® compliant equipment de-rating simulations to find the longest equipment life permitted by Code. These tools help keep process lines running, extend inspection intervals and minimize capital expenditures.

INSPECT is the one program, one install solution for mechanical integrity and fitness-for-service. This single program software architecture reduces IT, training and software maintenance costs by consolidating software modules from multiple vendors. It covers ASME pressure vessels, heat exchangers, piping and tanks – no additional software or custom programming required. INSPECT contains the functionality of COMPRESS so it can be used for greenfield and plant expansion projects too.

Extend Equipment Life, Reduce Compliance Risk

INSPECT helps Engineers safely extend equipment remaining life and inspection intervals. It can determine if your pressure equipment can support changes to process variables like temperature, pressure, and fill height. INSPECT also helps your facility meet OSHA and EPA requirements by producing detailed RAGAGEP compliant documentation for pressure vessels, heat exchangers, piping, and above ground storage tanks.

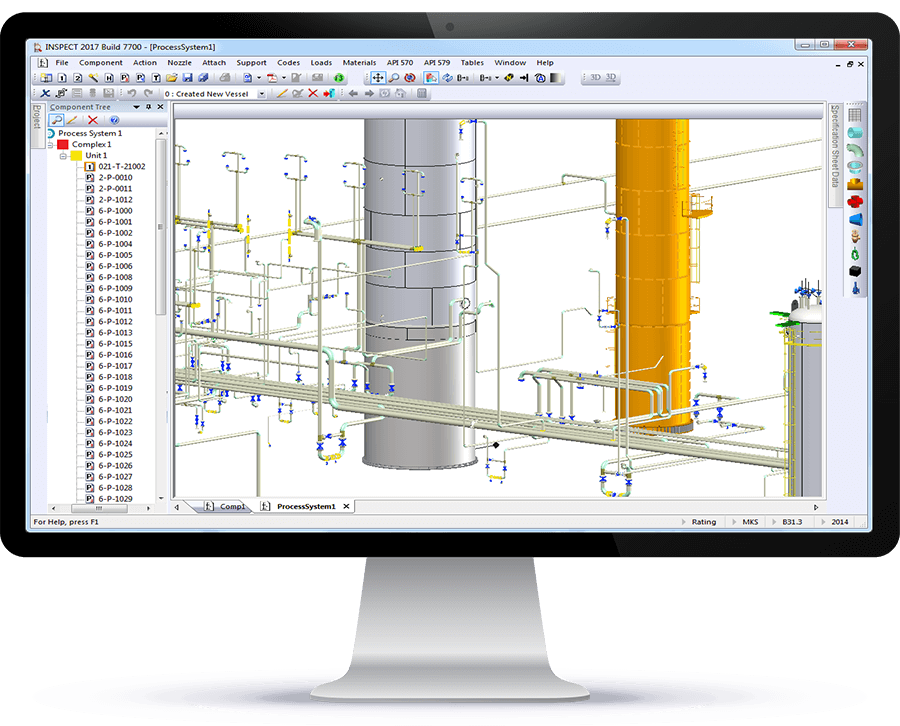

INSPECT manages your inspection data and shows it on the equipment in 3D. Our exclusive 3D plant modeling for Inspection and Pressure Equipment Engineers can organize corrosion loops into one 3D interface and specify which API RP 970 Corrosion Control Document applies. Perform a fitness-for-service damage assessment on a single shell or model an entire process system – with INSPECT it’s up to you.

INSPECT Increases Efficiency

3D plant layout programs are great for new construction activities; they were developed for that purpose. But what about your facility’s on-going maintenance needs? INSPECT addresses this by providing 3D plant modeling specifically for Inspection and Pressure Equipment Engineers. Engineers throughout your company can use INSPECT’s Process System Document to organize corrosion loops into one intuitive 3D interface. No need to search through endless, text-based tree lists. Quickly find what you need when you need it.