Extend Vessel Life By Applying NBIC 3.4

The design margin used to determine allowable stress was reduced from 4.0 to 3.5 in the A99 Addenda of the ASME Code. This often resulted in thinner, lighter vessels. At about the same time, the National Board Inspection Code (NBIC) introduced rules that allowed the use of these higher allowable stresses when re-rating vessels built to Codes prior to the A99 Addenda. Doing so effectively makes additional thickness available as corrosion allowance resulting in extended remaining life for older vessels. INSPECT includes the ability to automatically use the higher allowable stresses per NBIC Section 3.4 as appropriate. For vessels fabricated prior to 1968, INSPECT automatically uses allowable stresses based on the original design margin of 4.0

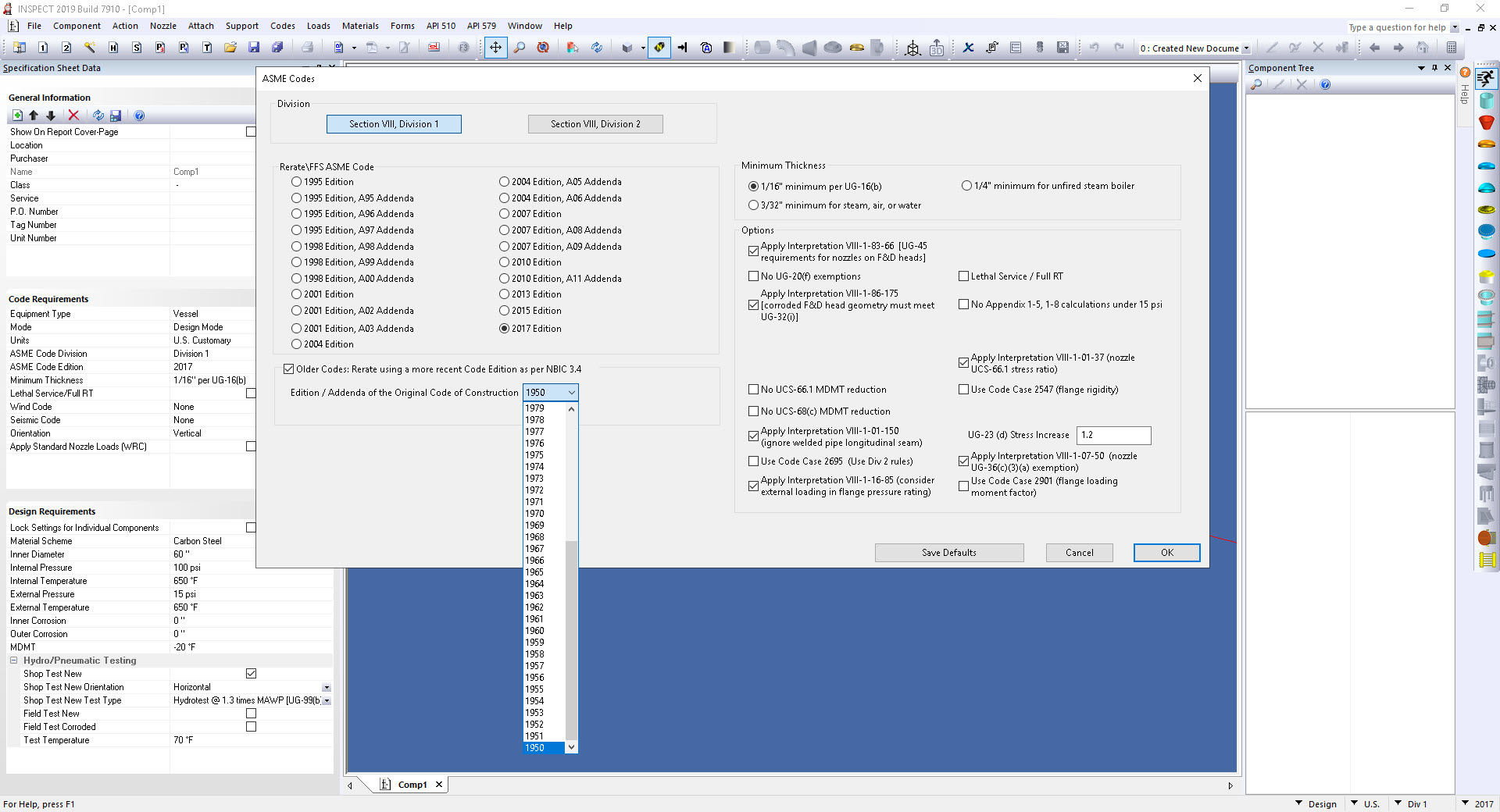

How INSPECT Implements NBIC 3.4

When the INSPECT option to re-rate a vessel using NBIC 3.4 is activated the following checks are made. The higher allowable stresses will be applied if the vessel:

If any of these checks fail, the pre 1999 Addenda stress allowables based on the 4.0 design margin are used. For more information see NBIC 3.4 and NBIC Interpretation 98-14 questions 4 and 5.

Extending Vessel Life by Applying NBIC 3.4 in INSPECT

INSPECT Featured Capabilities

Find Out More