API 510 Pressure Vessel Evaluations Using INSPECT

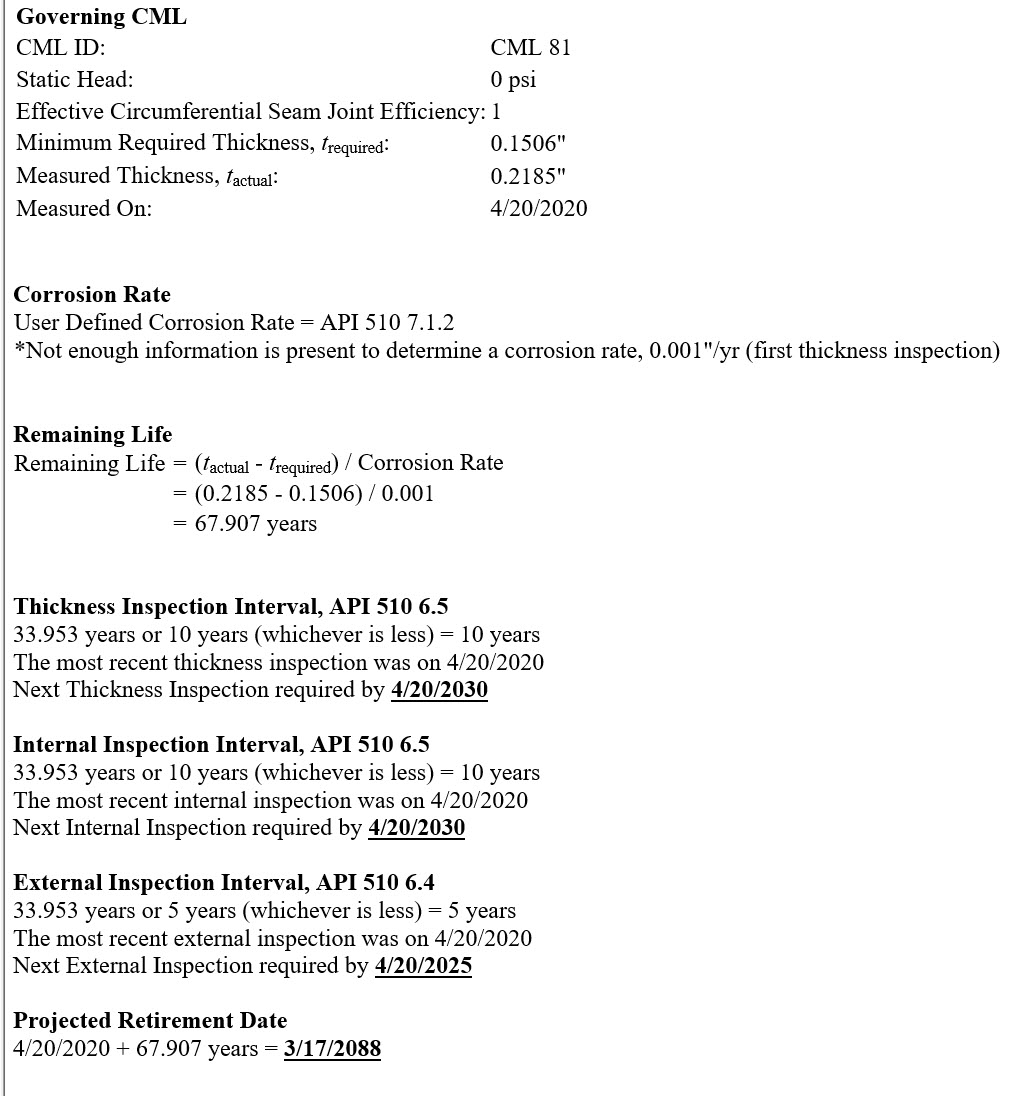

Pressure vessel Mechanical Integrity (MI) calculations and Fitness-For-Service (FFS) assessments are derived from the equipment’s original Code of Construction. INSPECT is built on Codeware’s flagship COMPRESS program and its ASME calculation engine. Because of this, INSPECT supports old ASME Codes of Construction. Like COMPRESS, INSPECT provides detailed audit trail reports that show how the minimum thicknesses (tmin‘s) were determined. For vessels built after 1987, the NBIC often allows the use of the higher allowable stresses permitted by more modern ASME Codes. INSPECT supports these NBIC rules resulting in extended equipment life and inspection intervals.

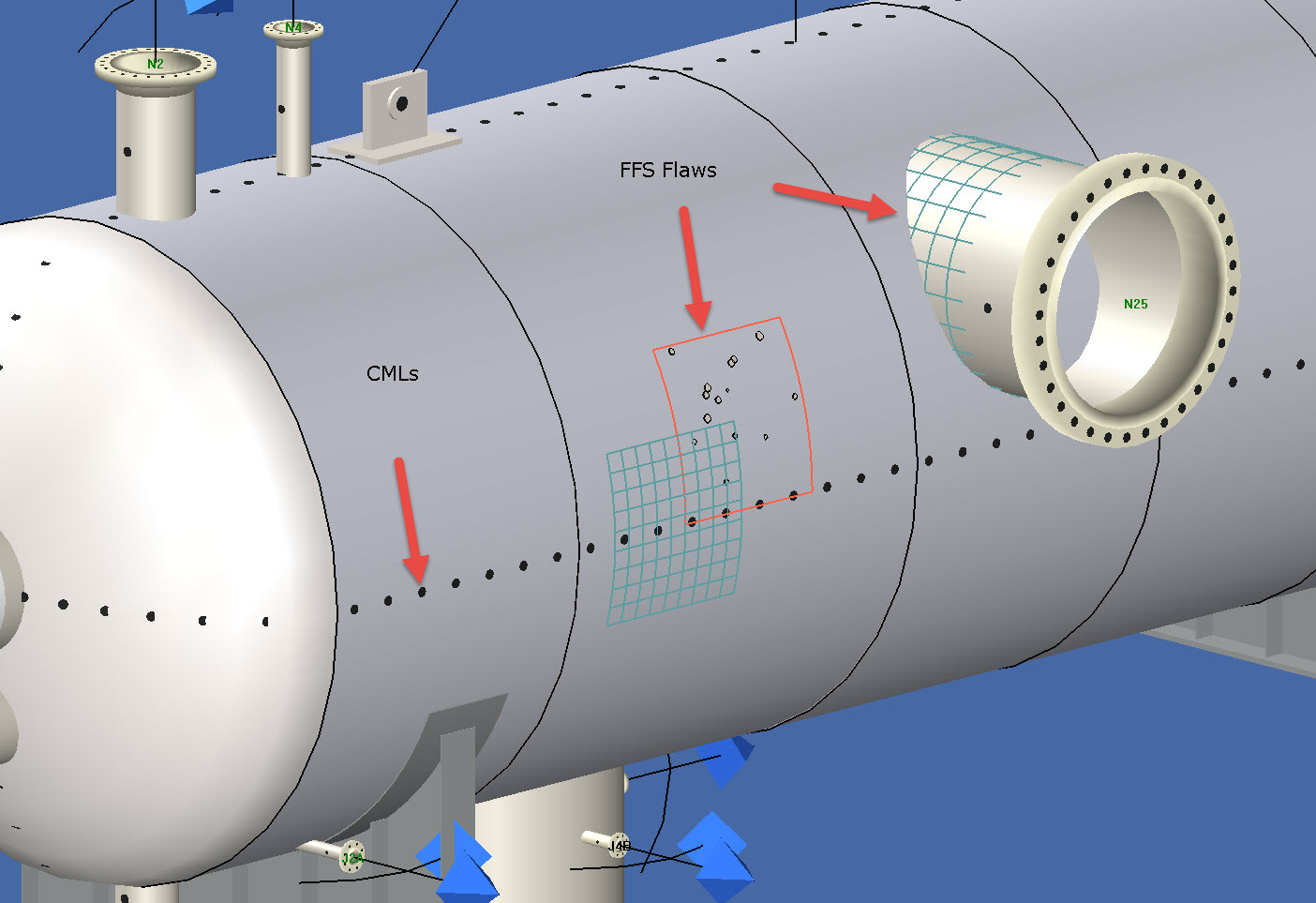

INSPECT performs both API 510 tmin calculations and API 579 FFS assessments within one platform. This eliminates the need for multiple MI and FFS software systems. With INSPECT, everyone works with the same equipment model ensuring that all departments have the same information. This eliminates data duplication and reduces the load on IT. It also eliminates the need to be trained on using multiple software tools.

Mechanical Integrity and Undocumented Pressure Vessels

A key component of any MI program is providing pressure vessel documentation. INSPECT can assist you with your undocumented pressure vessels. The INSPECT vessel wizard takes basic information and creates a working model to get you started.

The INSPECT workflow documents undocumented pressure vessels in three easy steps:

Mechanical Integrity And Nozzle Openings

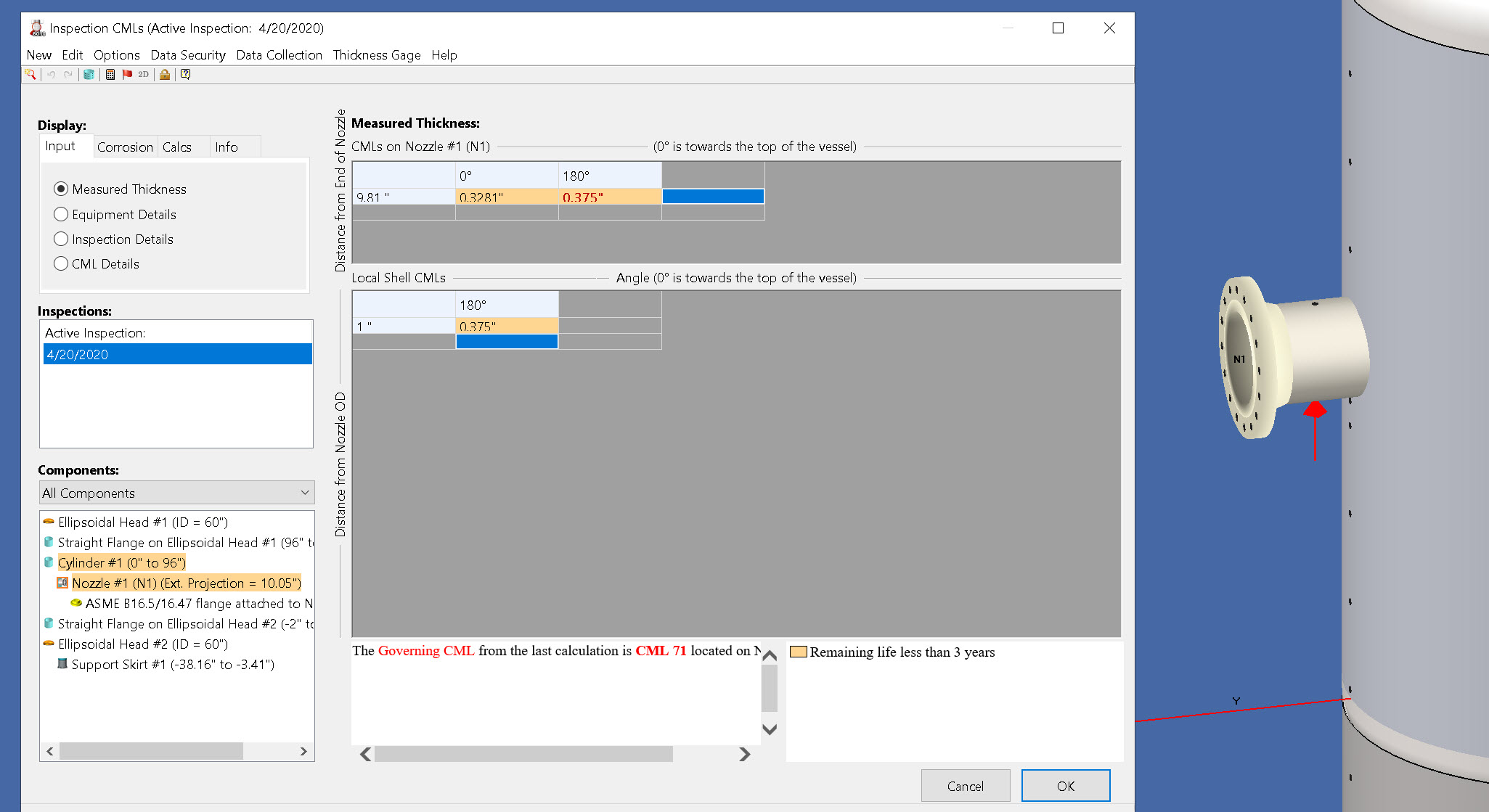

The proper assessment of nozzles and manways is a vital, but often overlooked, part of any pressure vessel MI inspection plan.

Take, for example, the simple vessel shown on the right. Normally a few points would be taken on the cylinder and the assessment would be performed. But in this case the nozzle governs. This then affects the remaining life of the entire vessel. INSPECT allows thickness measurements to be entered on and around the nozzle. This feature allows INSPECT to perform ALL the nozzle calculations required ensuring that both the tmin and area replacement rules are considered.