INSPECT API 579-1 FFS Overview

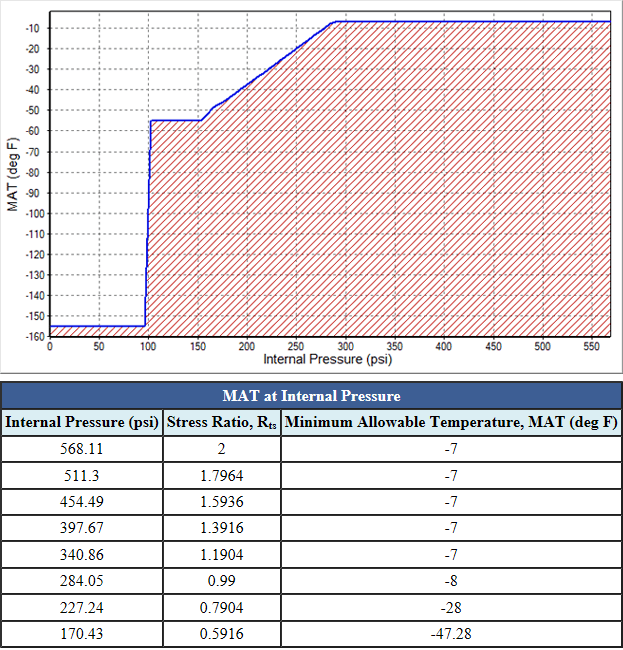

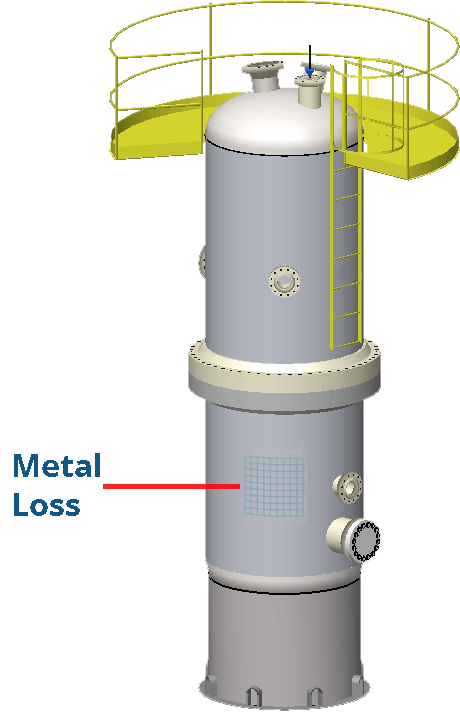

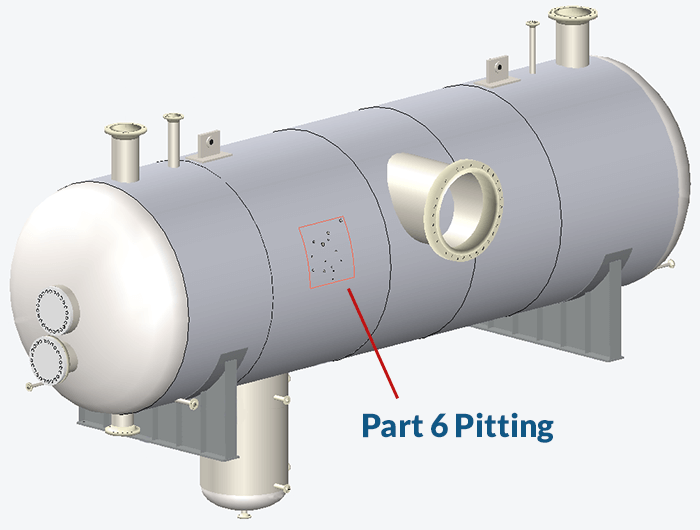

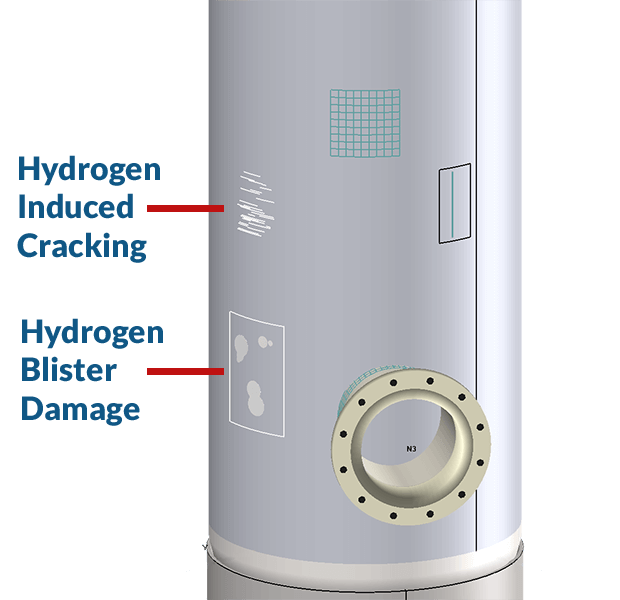

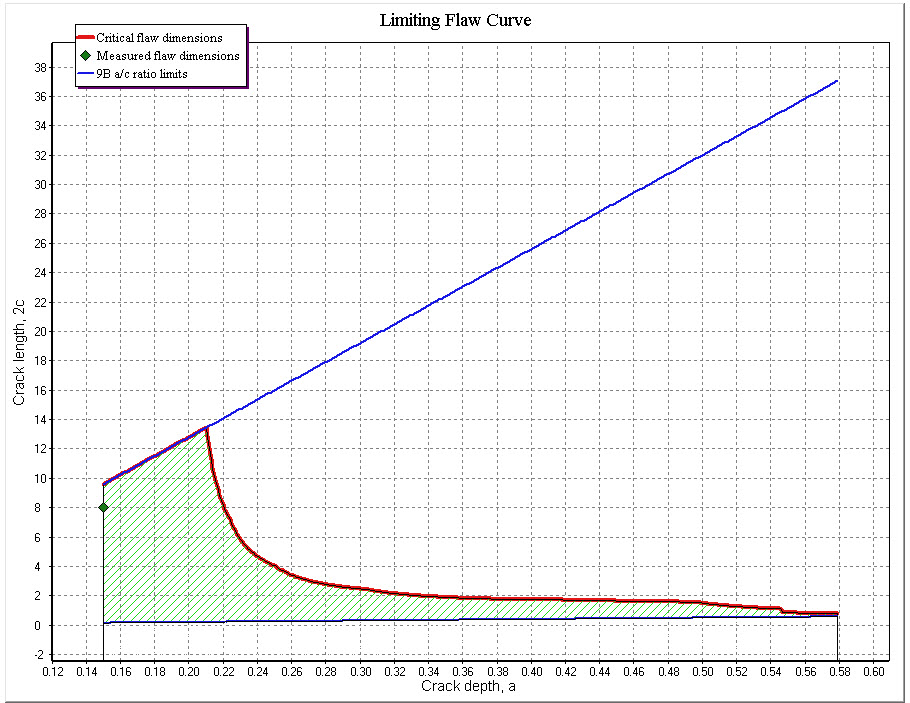

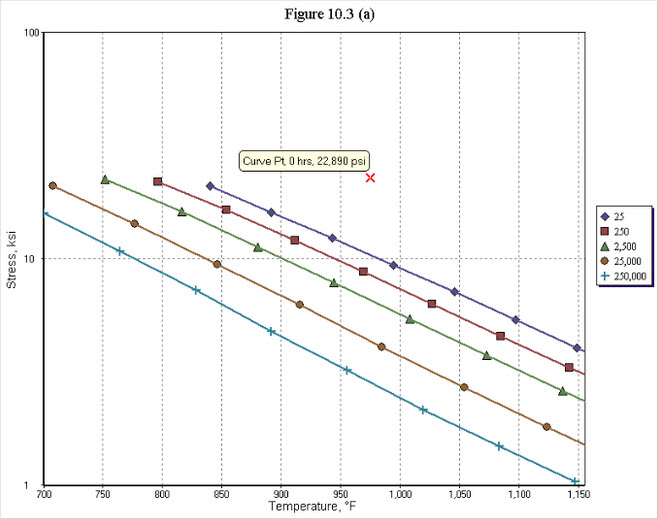

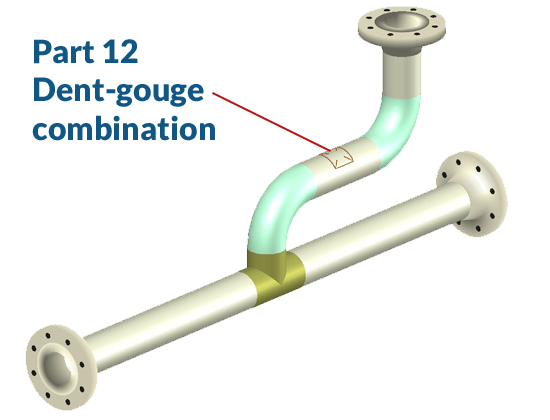

INSPECT’s API 579-1 FFS can assess individual components, complete vessels, or model entire process systems. Pressure vessels, heat exchangers, piping and tanks are covered within one program. INSPECT performs rigorous tmin calculations that can extend equipment remaining life and inspection intervals. INSPECT also organizes and adds context to your inspection data by showing CML’s and flaws on its 3D equipment models.

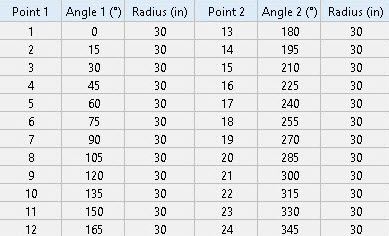

Below is the complete list of API 579-1 parts available in INSPECT.