INSPECT and Auto-Refrigeration

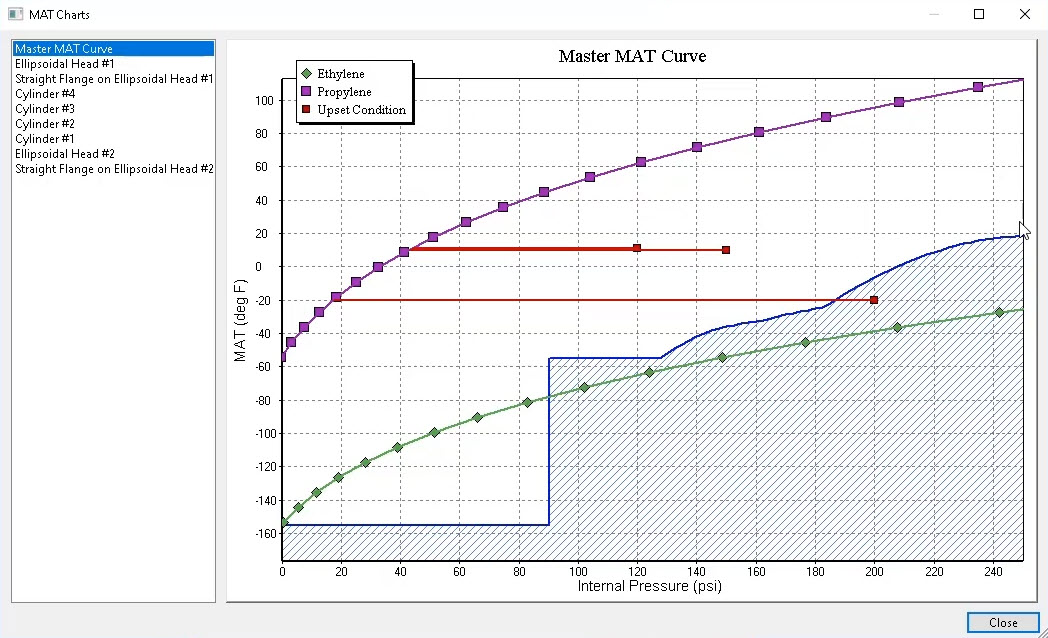

Minimum Allowable Temperature (MAT) curves, also referred to as Minimum Pressurization Temperature (MPT) curves, are used to ensure that carbon steel equipment can safely operate when exposed to low temperature conditions. Common applications include the olefin and hydrocarbon processing industries where safety concerns created by auto-refrigeration may occur. MAT curves are employed to determine which process conditions put equipment at risk of failure by brittle fracture. They are created by performing API 579 Part 3 assessments for all pressure-temperature conditions expected in service. Because of the number of calculations required, this has historically been an expensive, time consuming task. INSPECT automates this RAGAGEP procedure and shows how process conditions interact with the equipment’s Minimum Allowable Temperature (MAT).

INSPECT’s MAT Curve Benefits

Vapor Pressure Curves

Vapor Pressure Curves are sources of process information used by INSPECT to help determine a critical region of the integrity operating window. INSPECT combines equipment MAT and Vapor Pressure Curves to help operators consider the risk of auto refrigeration induced brittle fracture and ensure safe operations.

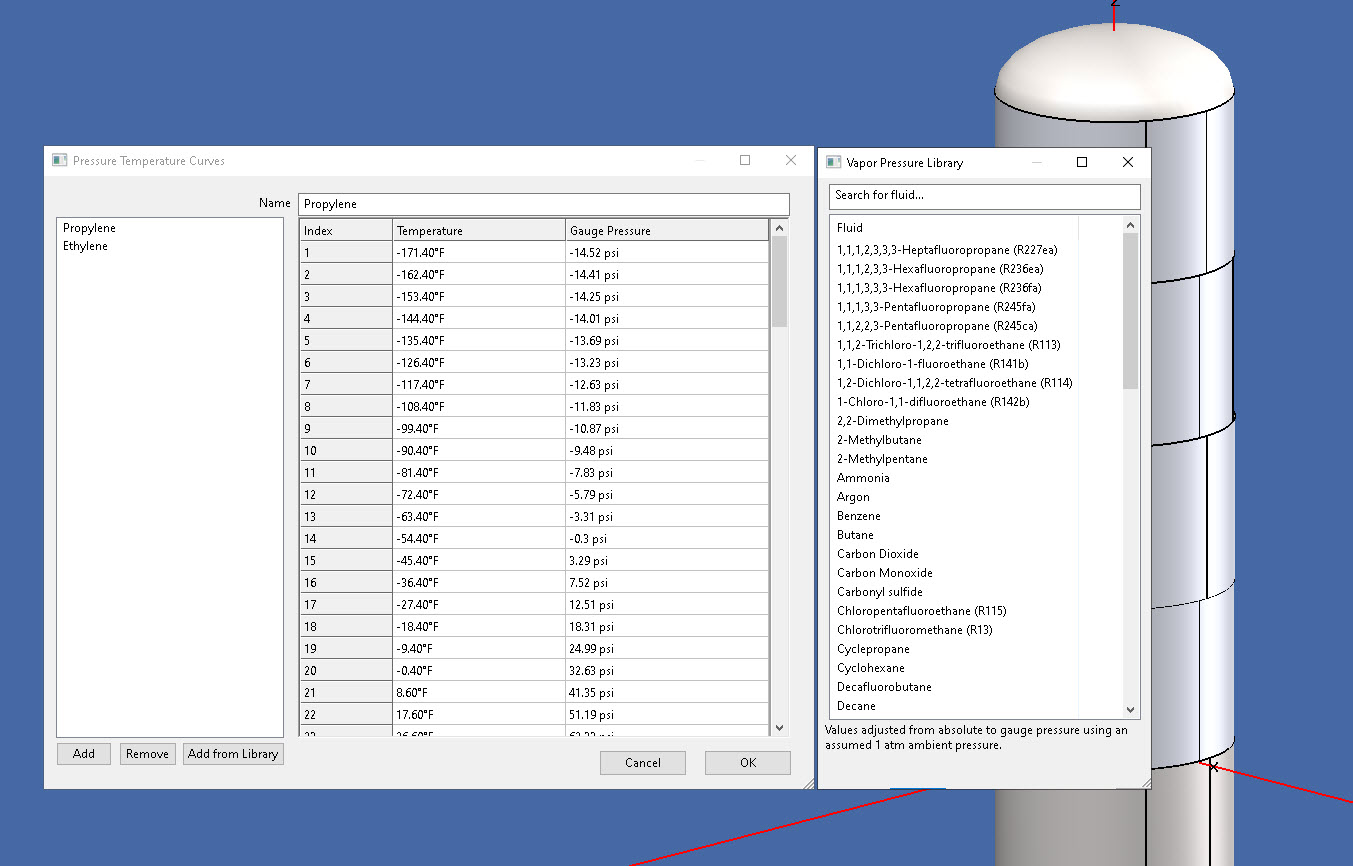

INSPECT provides a Vapor Pressure Curves library that covers fluids commonly used in the process industries. In Addition, INSPECT includes the ability to specify custom Vapor Pressure Curves. INSPECT plots the selected Vapor Pressure Curves on the MAT curve to identify process conditions that exceed the equipment’s MAT.

In addition to being plotted in the MAT, Vapor Pressure Curves in tabular form are also presented in the summary report.

Creating a Master MAT Curve in INSPECT

More information on auto-refrigeration and brittle fracture can be found at:

Prevent Brittle Fracture Failures by Following UCS-66 in COMPRESS and INSPECT

Auto-Refrigeration: When Bad Things Happen to Good Pressure Vessels by The National Board of Boiler and Pressure Vessel Inspectors

Auto-Refrigeration / Brittle Fracture Prevention And Process Safety Mitigation by Inspectioneering

Fitness-for-Service Forum: Minimum Pressurization Temperature (MPT) Curves: Why and How they are Going to Change by Inspectioneering

INSPECT Featured Capabilities