RAGAGEP and ASME® Pressure Equipment

On May 11, 2016 OSHA issued a standard interpretation on the topic of RAGAGEP and its proper application per OSHA 1910.119. For the case of ASME vessels and exchangers, it instructs the employer to identify and use the applicable consensus standards when preparing documentation to show compliance with the Process Safety Management (PSM) standard. Because the ASME Code is a new construction document and PSM addresses post construction use, additional specific standards apply including API 510 (vessels), API 570 (piping), API STD 653 (tanks) and API 579-1/ASME FFS-1.

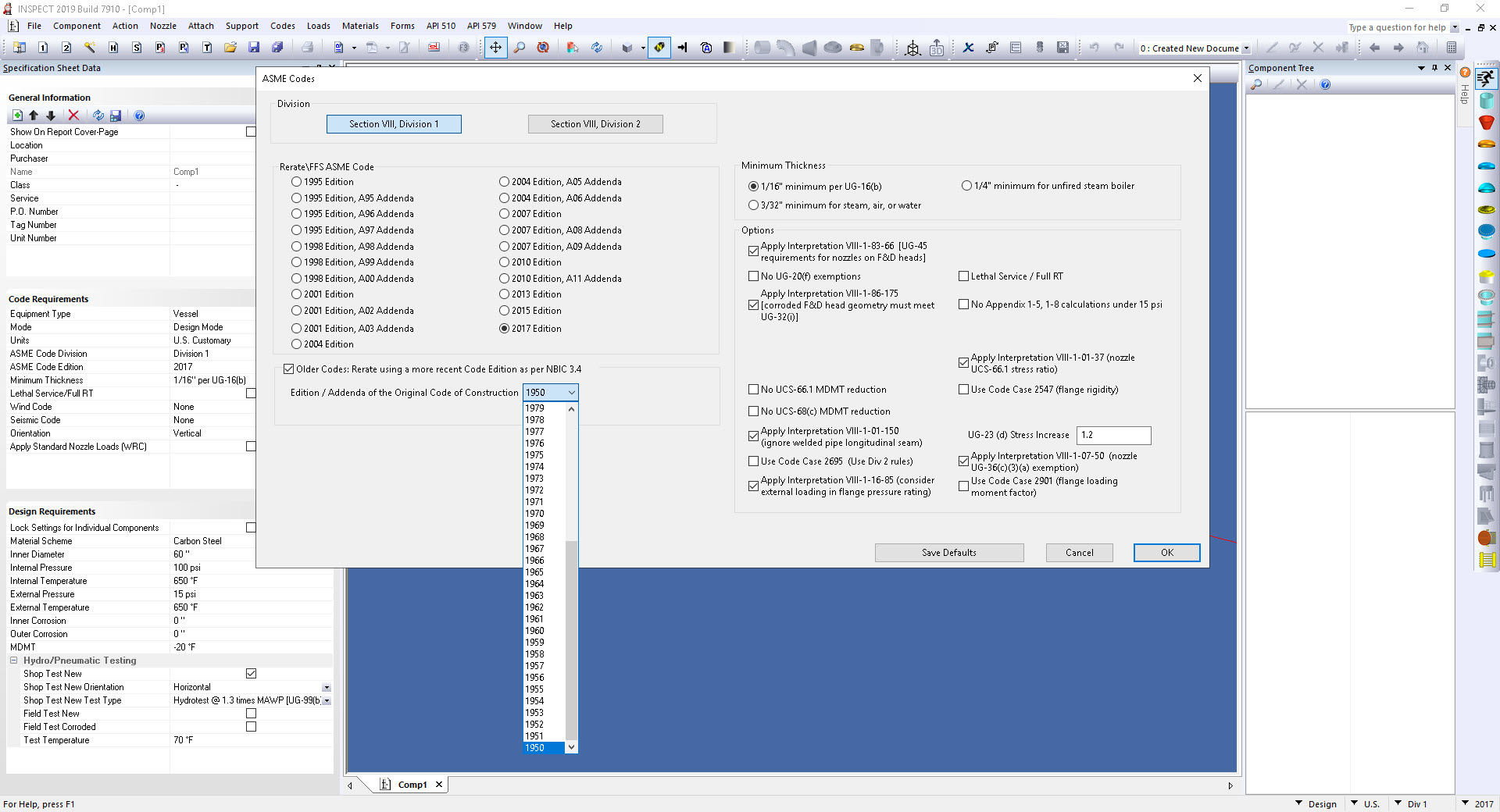

Note that the API documents listed above refer back to the original Code of construction (ASME VIII-1, VIII-2, B31.3, B31.4, TEMA). RAGAGEP specifies the use of the most recent API documents as they are regularly updated to reflect newly acquired information regarding damage mechanisms, operating experience and inspection technologies.

Save Money, Reduce Risk with RAGAGEP

In addition to regulatory compliance considerations, implementing RAGAGEP in your PSM program also makes good business sense. Rigorously following the RAGAGEP listed in NBIC Interpretation 98-14 and API 510 often permits the use of higher allowable stresses and\or joint efficiencies. This then results in lower tmin’s , extended inspection intervals and longer equipment remaining lifetimes.

Most companies commit substantial resources to gathering and storing inspection data. If your measurements and observations are not compared against RAGAGEP, your inspection efforts are not providing realistic results and your PSM program is not as cost effective as it could be.

INSPECT Software Helps Prove RAGAGEP Compliance

- Meet the Mechanical Integrity requirements of OSHA1910.119 (j) and EPA Title 40 part 68.73

Comply with OSHA’s interpretation of RAGAGEP as it relates to process equipment.

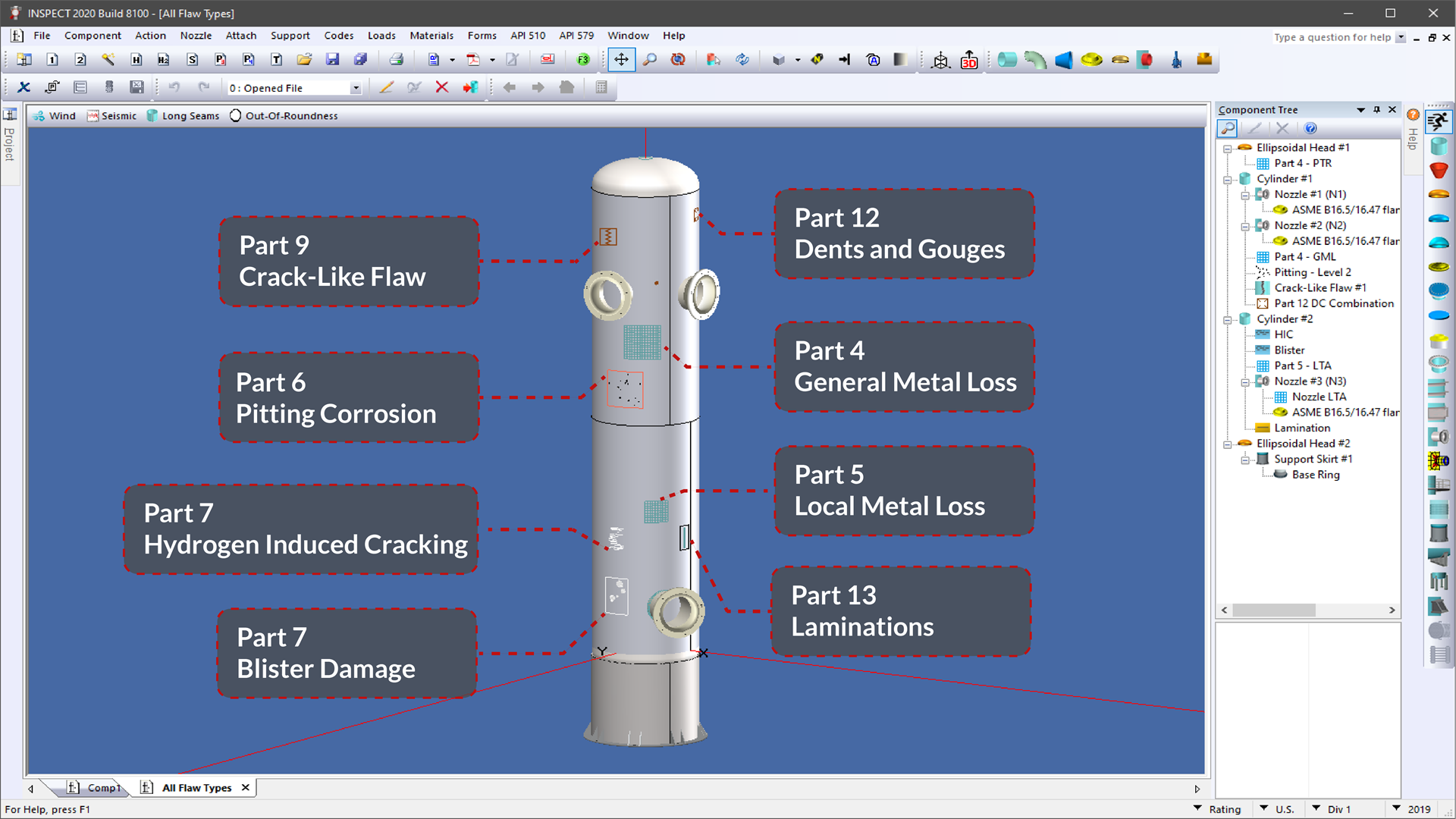

- Address the Fitness-for-Service (FFS) requirements of API 579-1.

Example RAGAGEP ARE:

Using the correct Code allowable stresses, joint efficiencies and equations when determining tmin’s.

Considering all the loads acting on the equipment. In addition to pressure these include liquid static head, weight, wind and seismic loads on the pressure vessel and its supports as well as (piping) loads on nozzle attachments.

Considering brittle fracture as a failure mode for carbon steel equipment using ASME VIII-1 paragraph UCS-66 or API 579-1/ASME FFS-1 Part 3. This may, for example, affect equipment start-up and field hydrotest conditions.

Using all applicable Engineering Methods, Codes and Standards.

Implemented in INSPECT Software.

These ARE NOT RAGAGEP:

- Simplistic internal pressure formulae for calculating tmin or ignoring the external pressure tmin (a very involved calculation).

Nozzle tmin’s arrived at by only considering ASME VIII-1 paragraph UG-45. Area replacement (UG-37), proximity to other openings and more must be taken into account.

Black box computer reports with no way of verifying (auditing) the correctness and completeness of the ASME and API calculations performed.

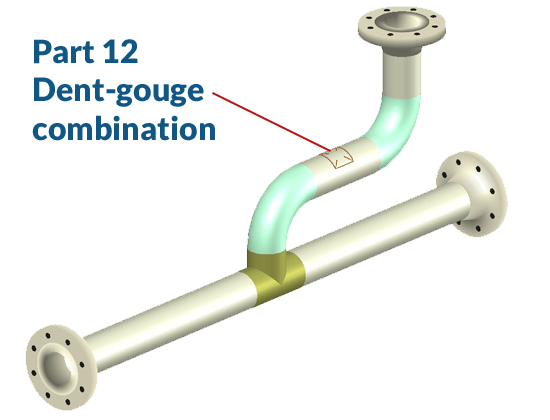

Having no ability to perform fitness-for-service (FFS) assessments. Most competing Inspection Data Management Systems (IDMS) only consider general metal loss. General metal loss is, however, not the only in-service damage experienced by process equipment. Without FFS, how does your company ensure that it is safe to continue operating equipment with pitting, local thin areas, cracks, dents and gouges etc.?

INSPECT Featured Capabilities