Shopfloor Generated Drawings and Weld Maps

Shopfloor Generated Drawings and Weld Maps

Note: The Codeware Interface is included at no additional charge with each current license of COMPRESS or INSPECT. If your company has COMPRESS or INSPECT, you already have access to the efficiencies provided by the Codeware Interface.

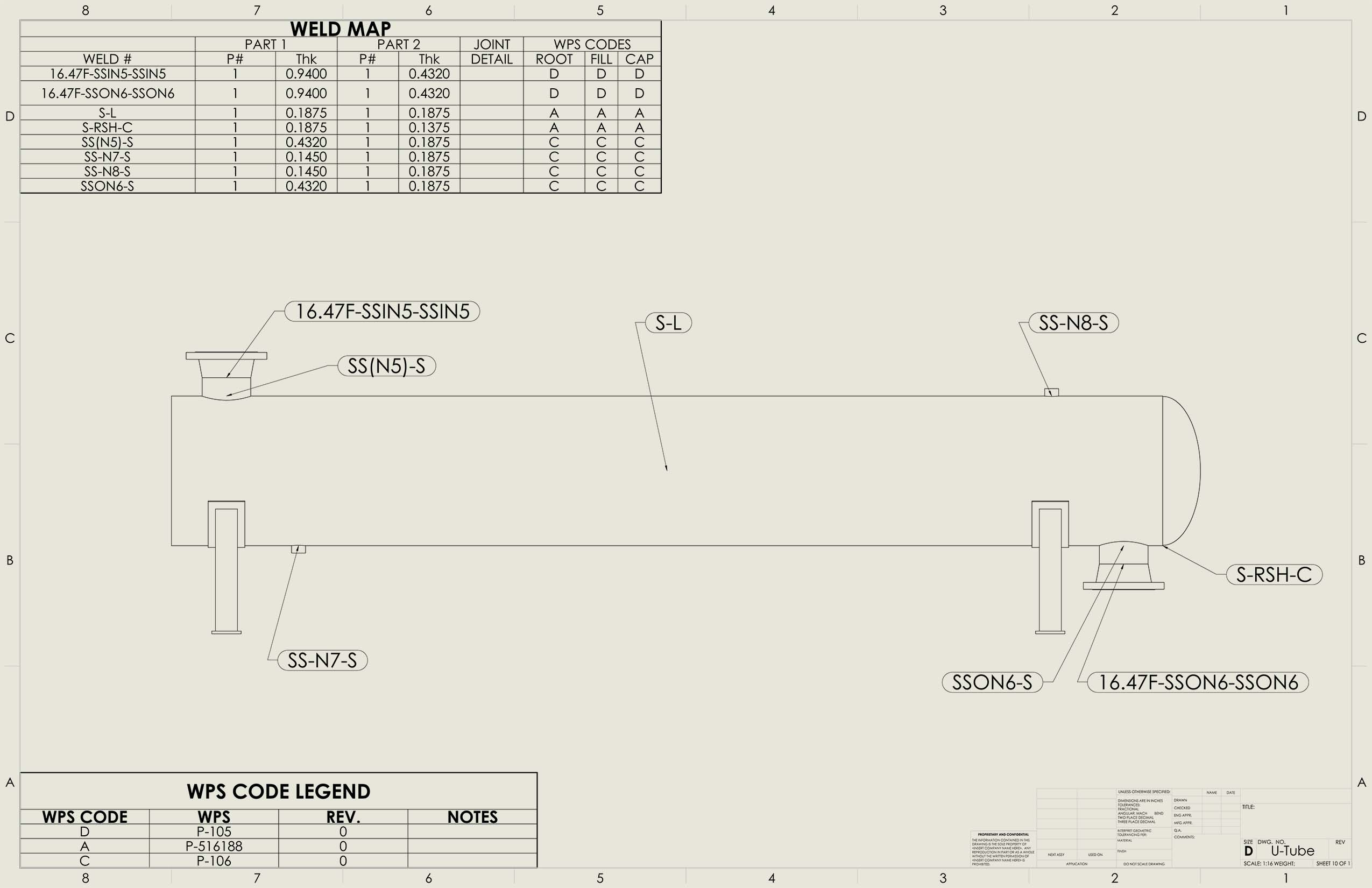

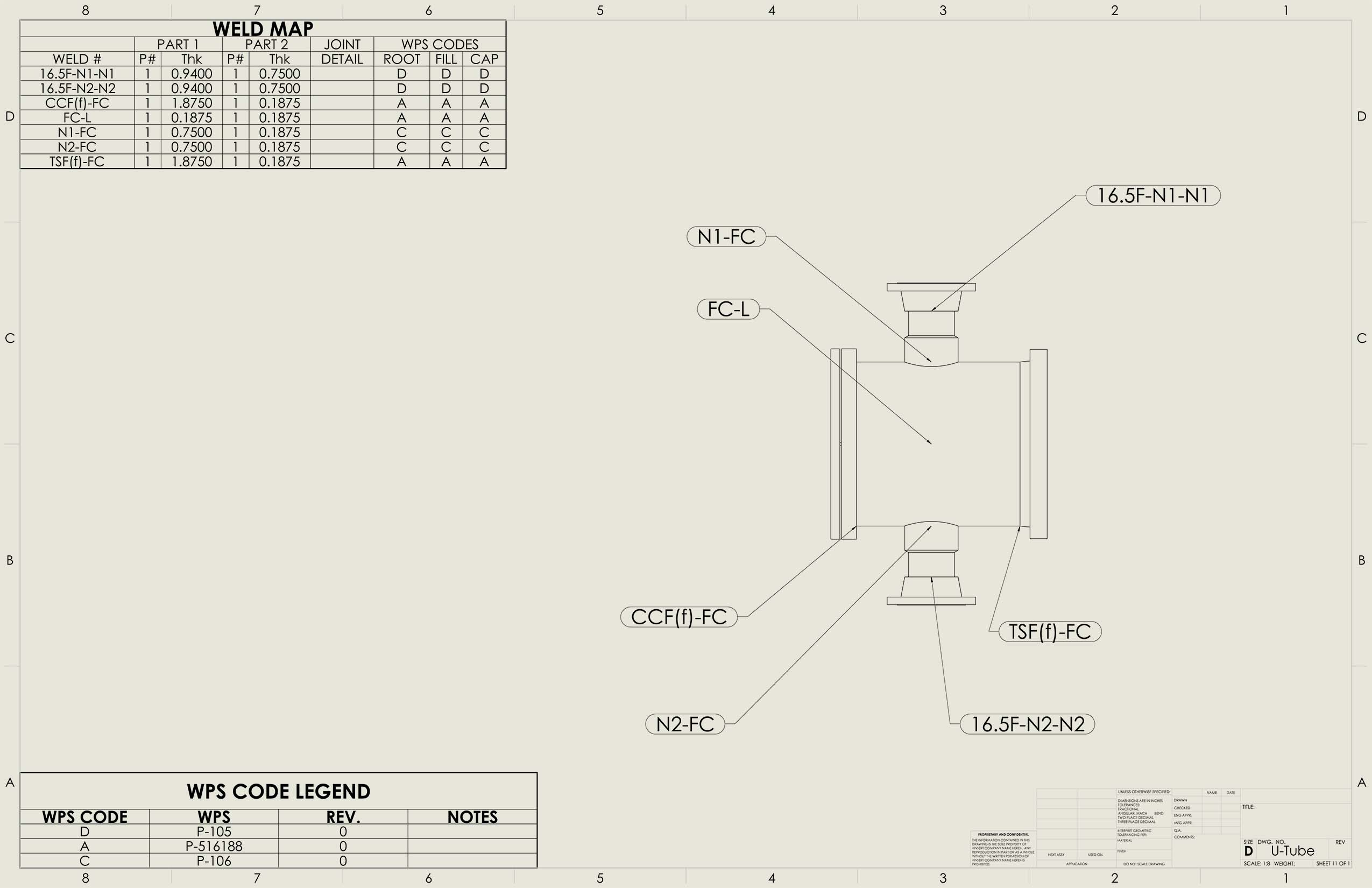

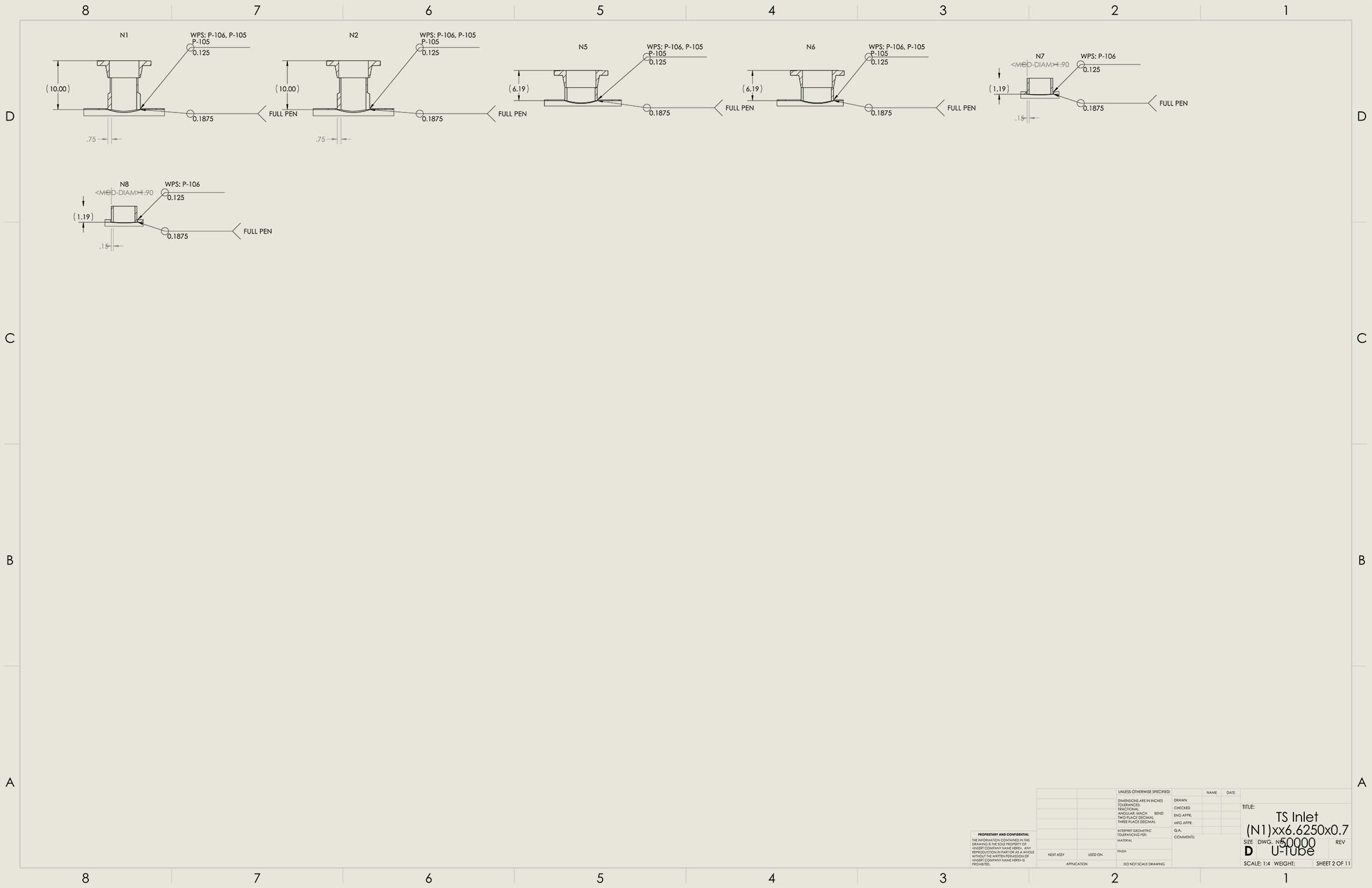

Weld Maps & Drawings Easily Customized To Suit Your Requirements

Weld Maps & Drawings Easily Customized To Suit Your Requirements

Another benefit of Shopfloor’s integration with the Codeware Interface is how it leverages the power of SOLIDWORKS. It does this through the use of advanced solid modeling techniques including Assembly Representations, Configurations, Features, Sketches, Sheet Metal, and Mates. All of the data imported from COMPRESS and Shopfloor is easily accessible from within SOLIDWORKS. Don’t like the way your drawings or weld maps look? Need more or less data shown in your tables? Changing these and other details on Codeware Interface created drawings is easy to do using built-in SOLIDWORKS tools. For those new to SOLIDWORKS, the Codeware Interface also includes a selection of standard detail drawing templates to help get you started.