COMPRESS

Smarter Pressure Vessel Software

COMPRESS saves companies time and money by helping engineers efficiently design and rate ASME® VIII pressure vessels and heat exchangers.

Benefits include industry-standard ASME calculation reports, no additional charge automatic drawings, cost estimating and the best technical support services in our industry.

INSPECT

Comprehensive API 579-1 FFS Software

INSPECT is a mechanical integrity solution that combines Fitness-For-Service and inspection data management into one integrated 3D software platform. INSPECT helps companies safely extend equipment remaining life and reduce regulatory compliance risk. It documents undocumented pressure vessels and assists Engineers make run, re-rate, repair or replace decisions for pressure vessels, heat exchangers, piping and storage tanks.

INSPECT replaces multiple software packages from different vendors with a single user interface that organizes your facility’s pressure equipment into intuitive and efficient 3D models. When it becomes necessary to repair your pressure equipment, INSPECT’s integration with Shopfloor simplifies that process too.

Shopfloor

ASME IX and AWS Welding Management Software

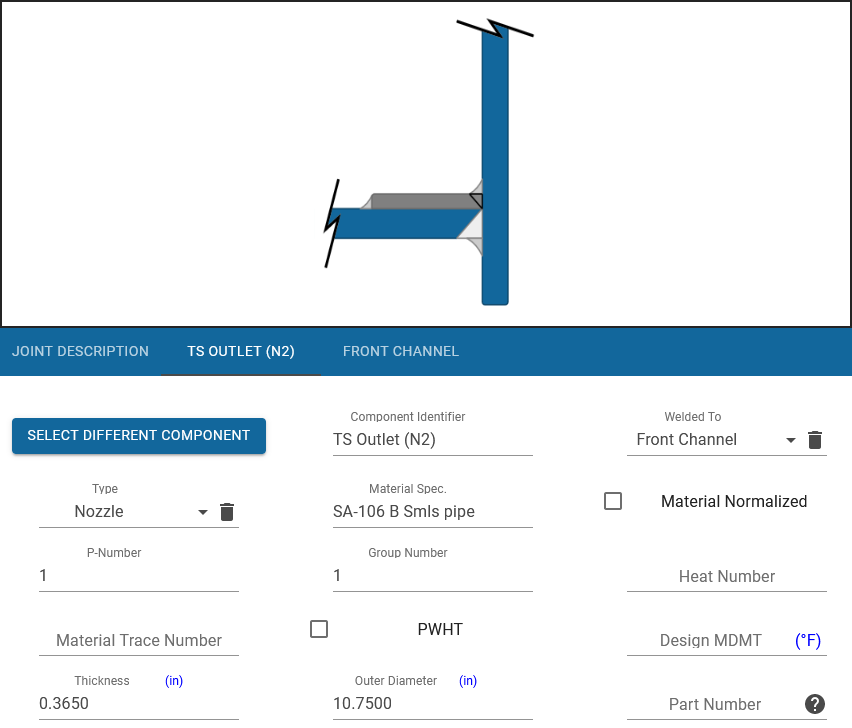

Create and track weld forms, customers, jobs, work locations, welders, bolters and more using Shopfloor’s welding management system. Shopfloor completely replaces paper based systems and bridges the gaps between your Engineering, Drafting, and Quality Control departments.

Shopfloor simplifies welding management and helps fabricators avoid auditor “gotchas”. It features integration with COMPRESS and INSPECT created pressure vessels and heat exchangers. The sharing of WPS information between Shopfloor and COMPRESS results in time savings and fewer errors. Shopfloor is a cloud based welding documentation software application that allows unlimited user access while providing the latest in data management, access, and security.

In addition, the available Shopfloor setup service helps to to get you up and running quickly.