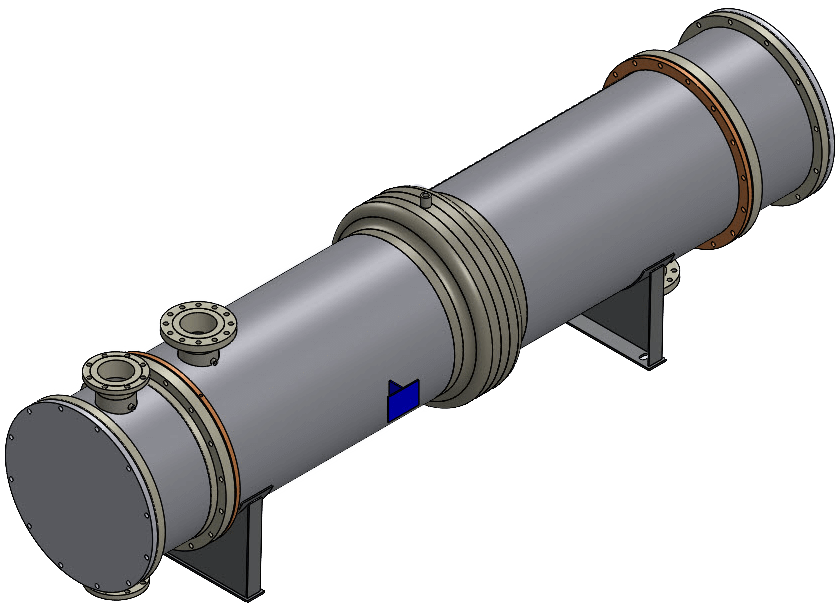

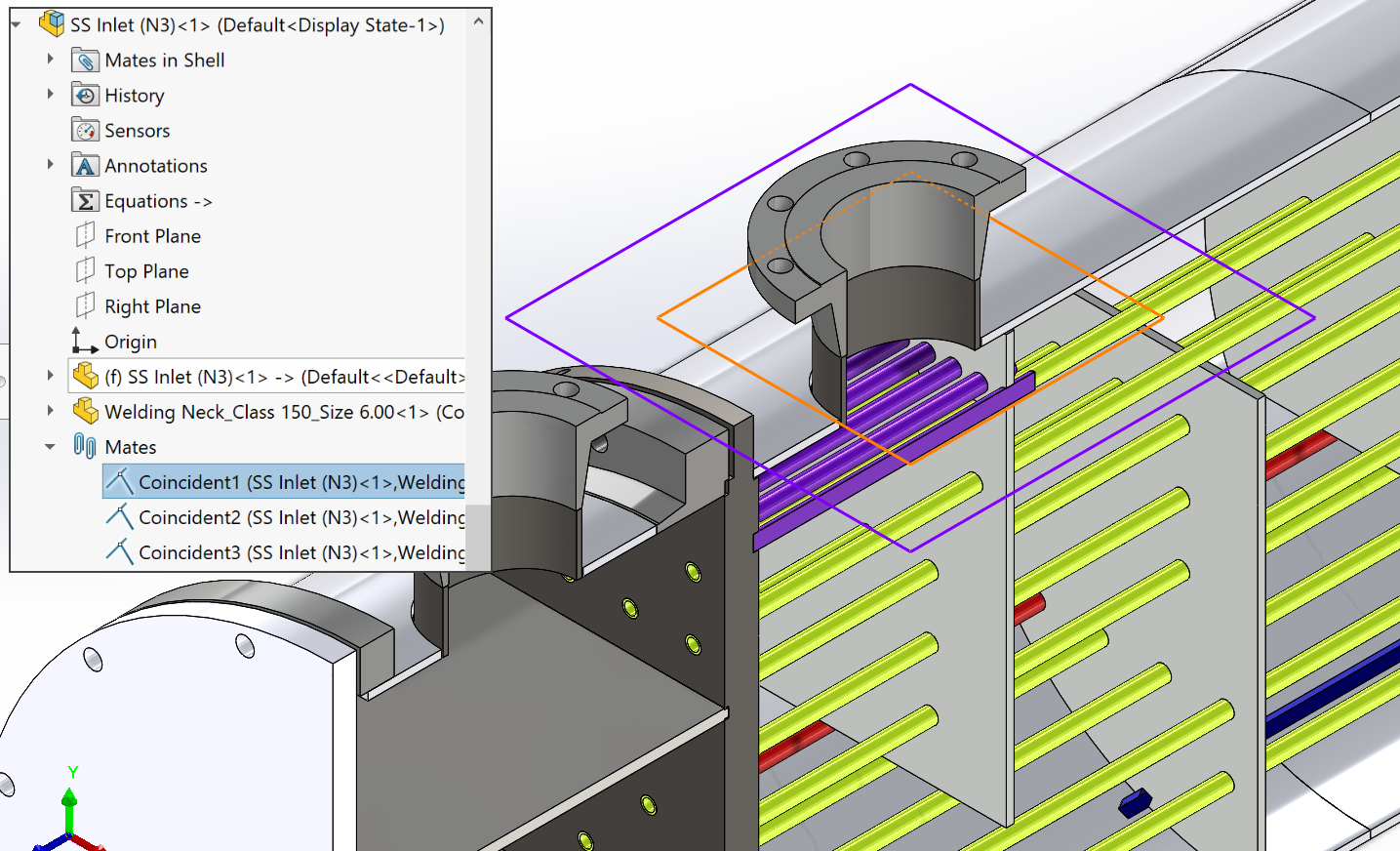

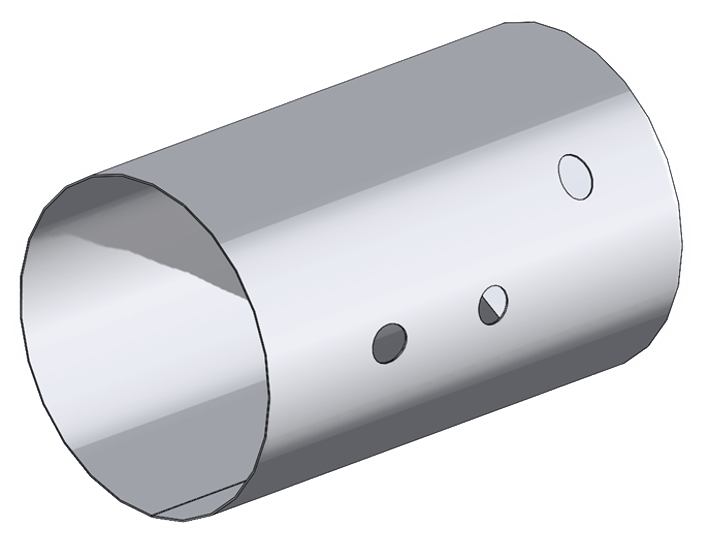

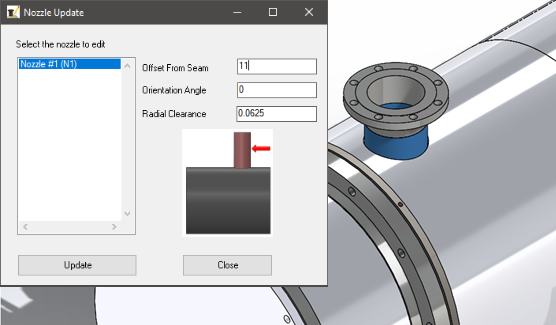

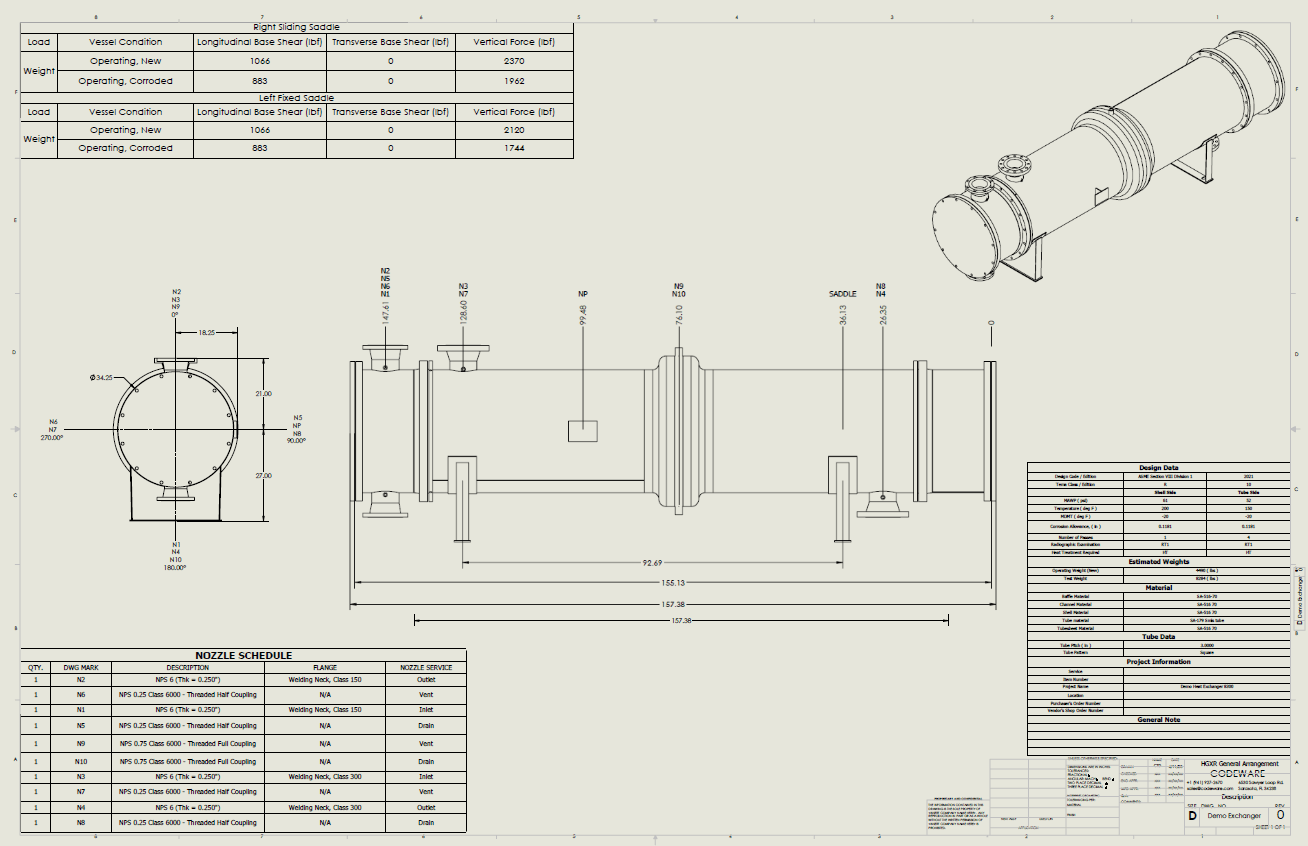

The Codeware Interface (CWI) is a SOLIDWORKS\Inventor add-in that generates pressure vessel drawings and solid models from COMPRESS designs. This time saving functionality is not available from any other pressure vessel design system. The CWI is included at no additional charge with each current COMPRESS or INSPECT license.