COMPRESS + Shopfloor = More Efficient ASME Fabrication

Using COMPRESS + Shopfloor you can design ASME equipment, estimate its cost, produce fabrication drawings and manage ASME IX welding documents in one consistent, unified system. Expensive custom programming is no longer required to get your Engineering, Estimating, Drafting and Quality Control departments working together.

Estimators are equipped with the COSTER® add-in for Excel®. Drafters harness the power of AutoDesk® Inventor® or SOLIDWORKS® through the Codeware Interface. Quality Control employs Shopfloor to track jobs and manage weld documentation and welders. And of course, Vessel Designers use the standard in pressure vessel design, COMPRESS.

Do you outsource your vessel design work? If your design consultant uses COMPRESS, our XML3D file output provides all the benefits of Shopfloor integration for you too.

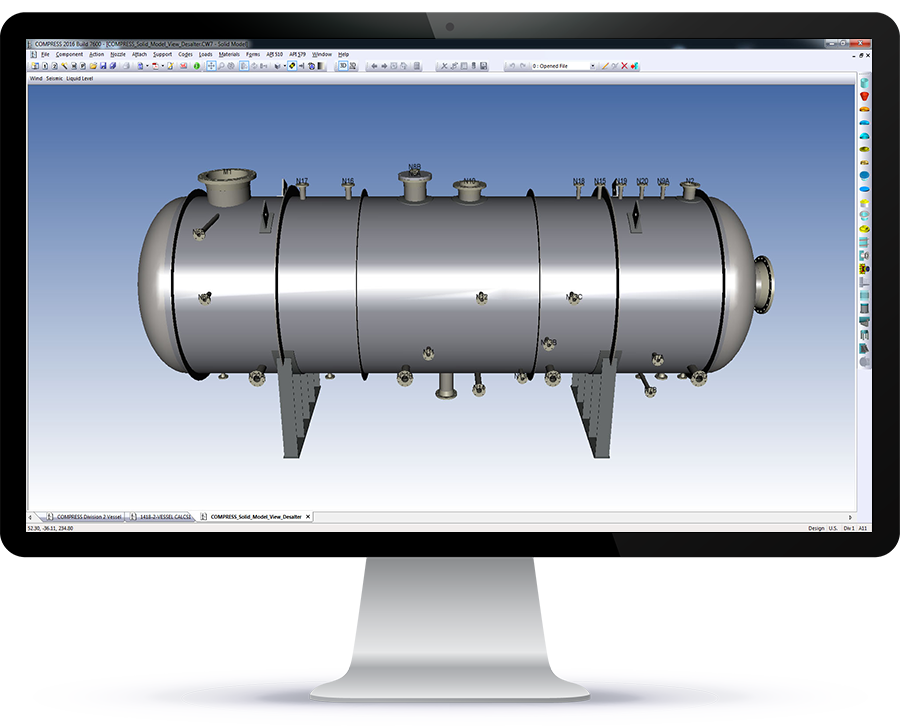

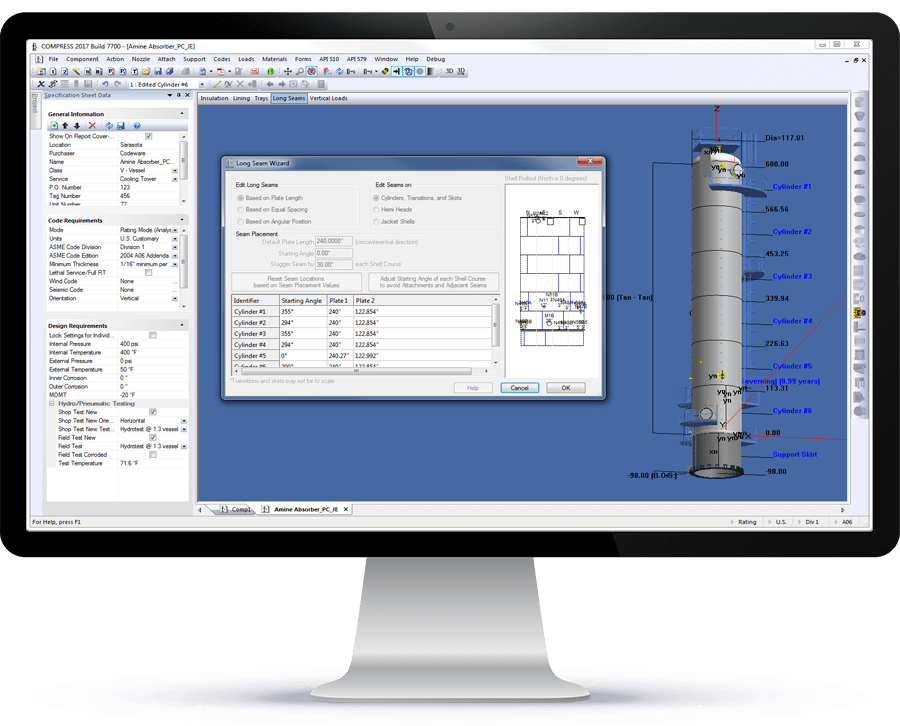

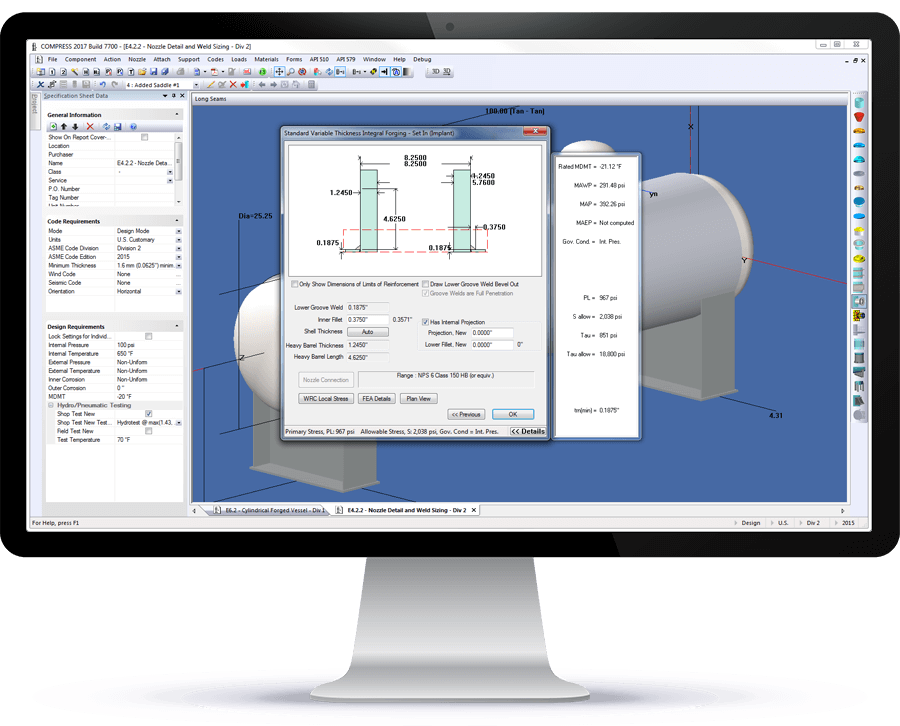

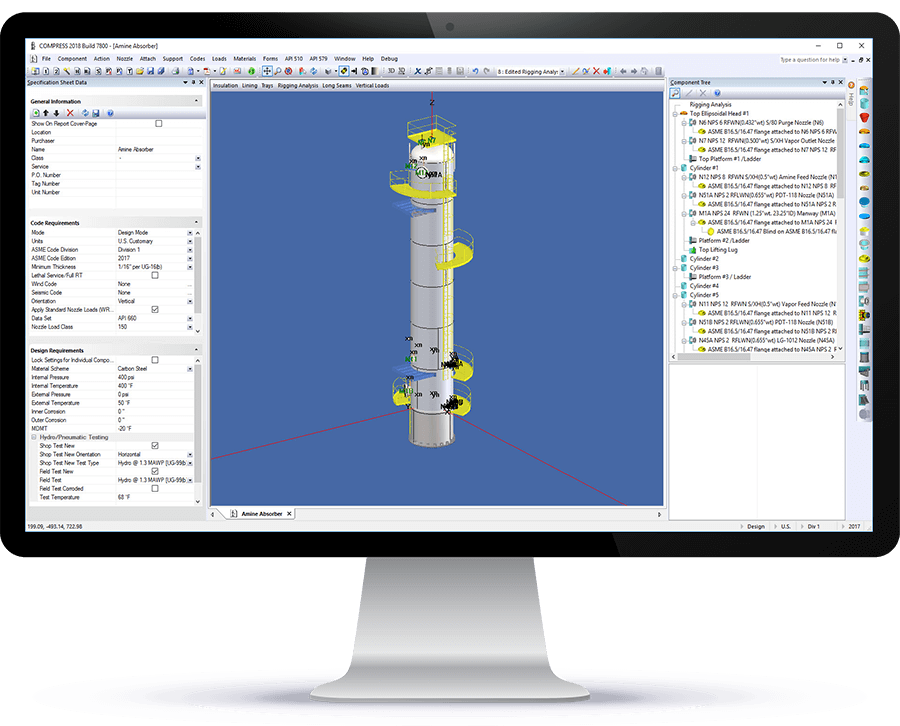

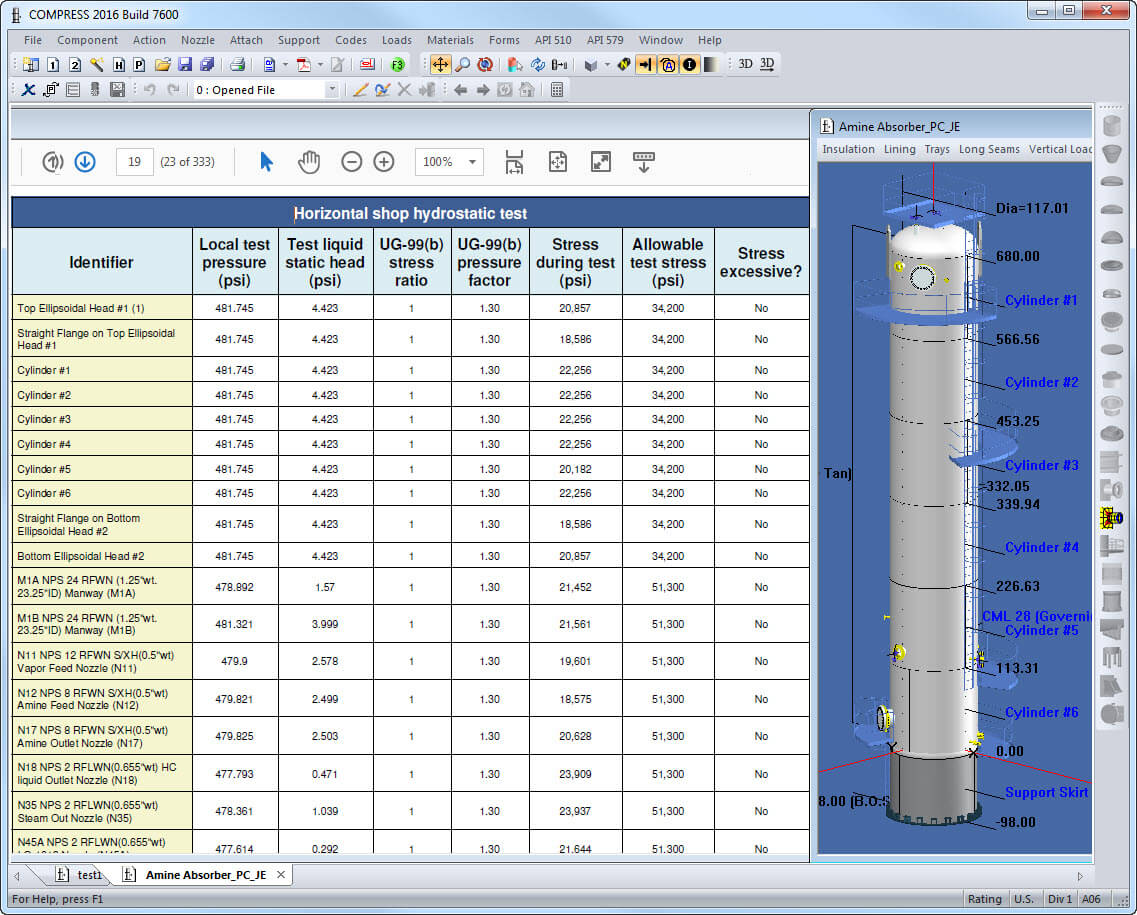

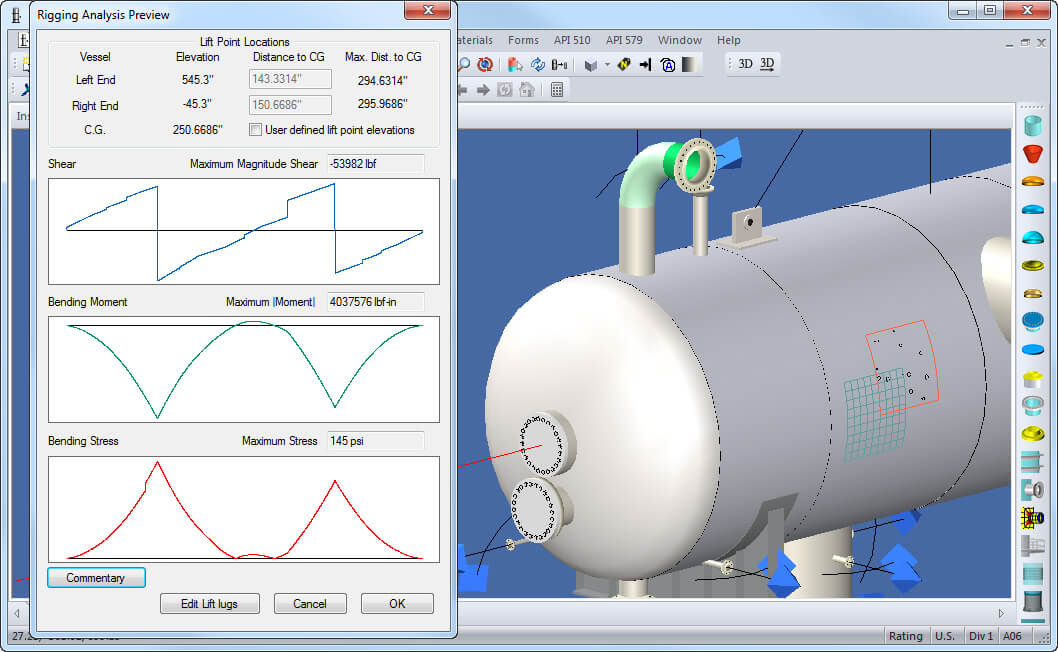

Faster ASME Designs With Fewer Mistakes

The ASME Code is a complex (and sometimes confusing) set of mandatory rules subject to regular updates. It’s challenging to stay current with the ASME Code, building codes, related Codes and Standards, good engineering practices, customer specifications and advances in computing. A sale lost or worse yet, a vessel rejected because something was missed is simply not acceptable in today’s business climate. COMPRESS has been in widespread use for over 34 years because it guides designers through the ASME Code and helps them avoid Code related errors and omissions. COMPRESS is also the best value because it includes capabilities that competing products either do not offer or charge extra for. Time saving features such as nozzle copy and paste, lift lugs, shipping saddles, nameplates, drawings, estimating and even engineering support are either not available or optional with others but come standard with COMPRESS.

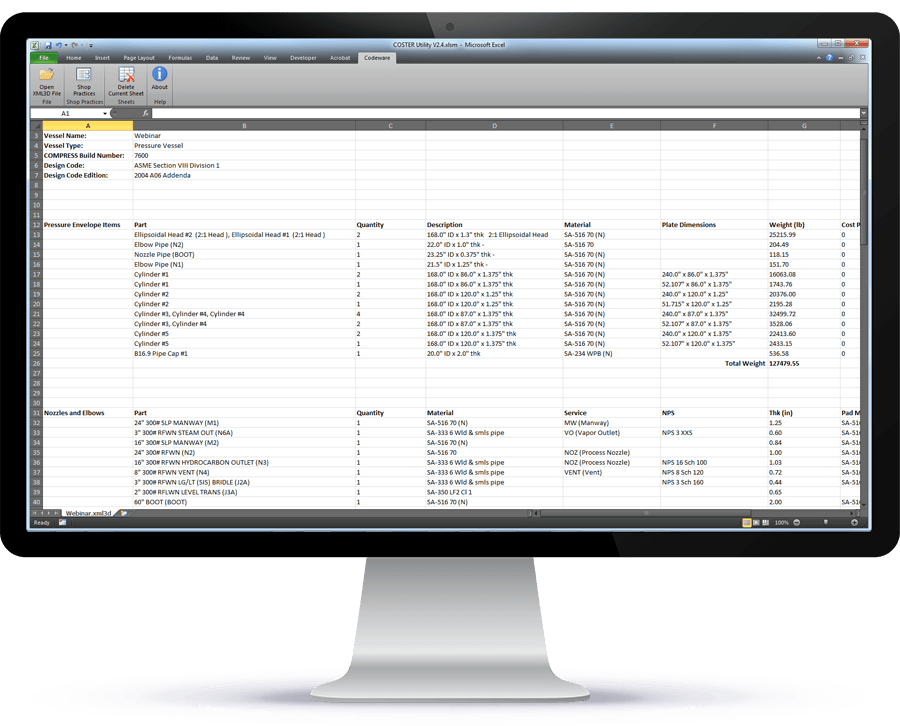

Quicker ASME Fabrication Cost Estimates

Included with the purchase of COMPRESS, the COSTER Excel add-in imports COMPRESS designs and creates customizable cost estimates. Consistent and accurate cost estimating is vital to your company’s bottom line. Too high, you lose the bid and too low, you lose money. Automating the costing function to the largest extent possible is a strategic imperative that is often only appreciated after your Estimator retires or quits.

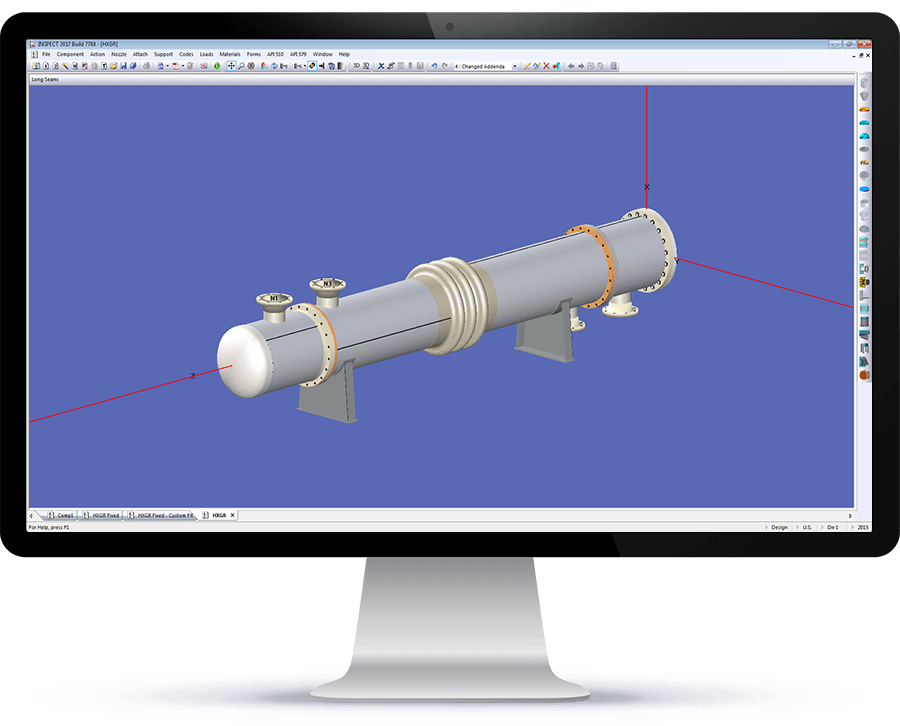

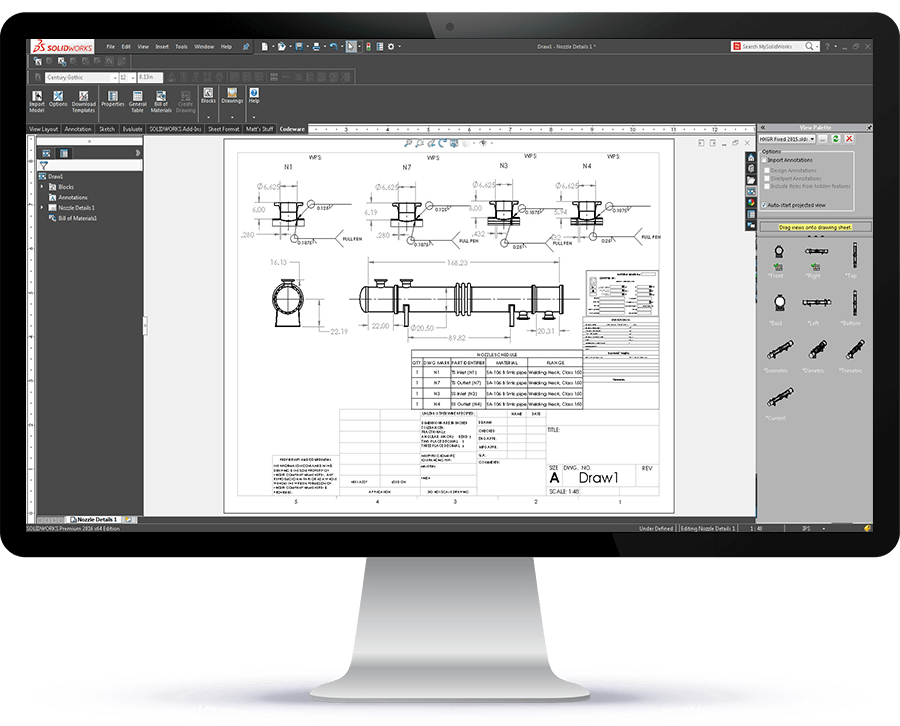

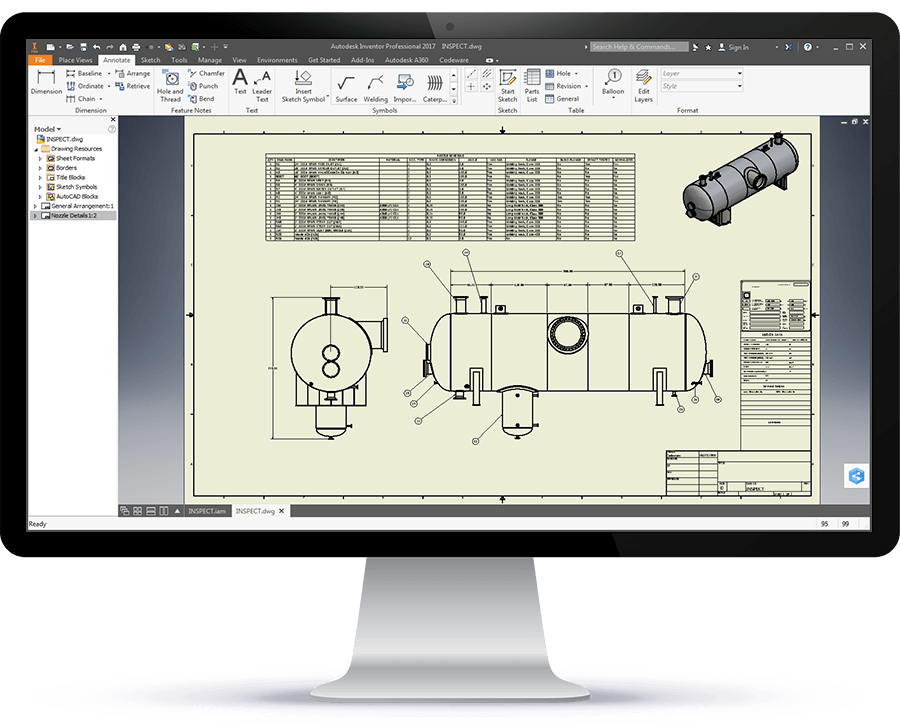

Eliminate the Drafting Bottleneck

Do you need to get more ASME fabrication drawings done but are short on staff? COMPRESS increases drafting productivity by including the Codeware Interface (CWI), an add-in for Autodesk Inventor and SOLIDWORKS. The CWI transfers COMPRESS design data so it does not have to be re-entered into your drafting system. The CWI includes Drafter 3D, a feature that produces to-scale 2D fabrication drawings from COMPRESS solid models. Drafting personnel also appreciate that the CWI supports advanced smart solid modeling techniques including the use of Assembly Representations (Inventor), Assembly Configurations (SOLIDWORKS), features and sketches.

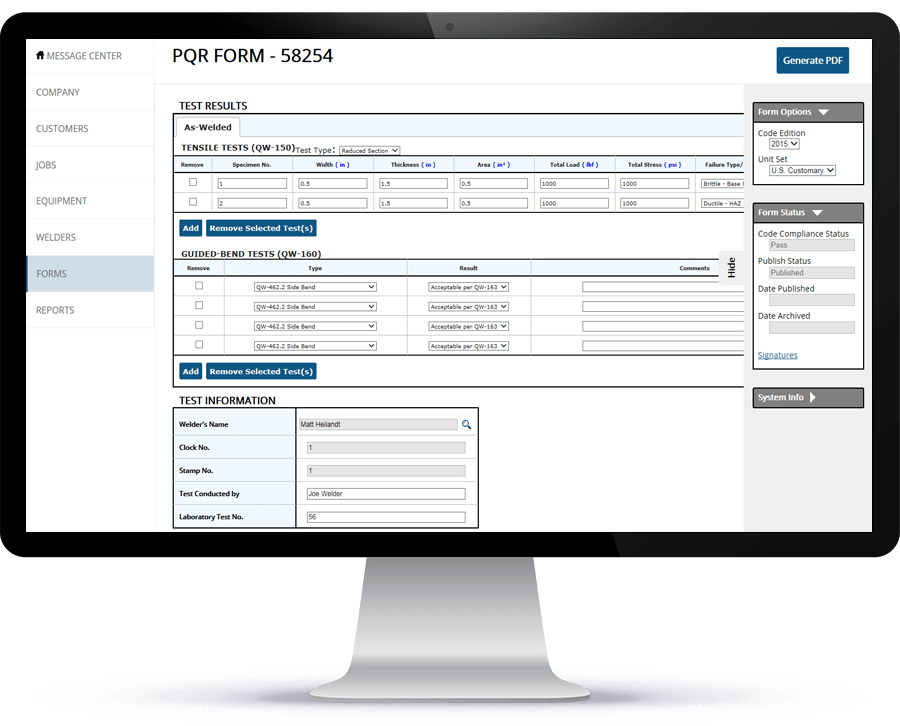

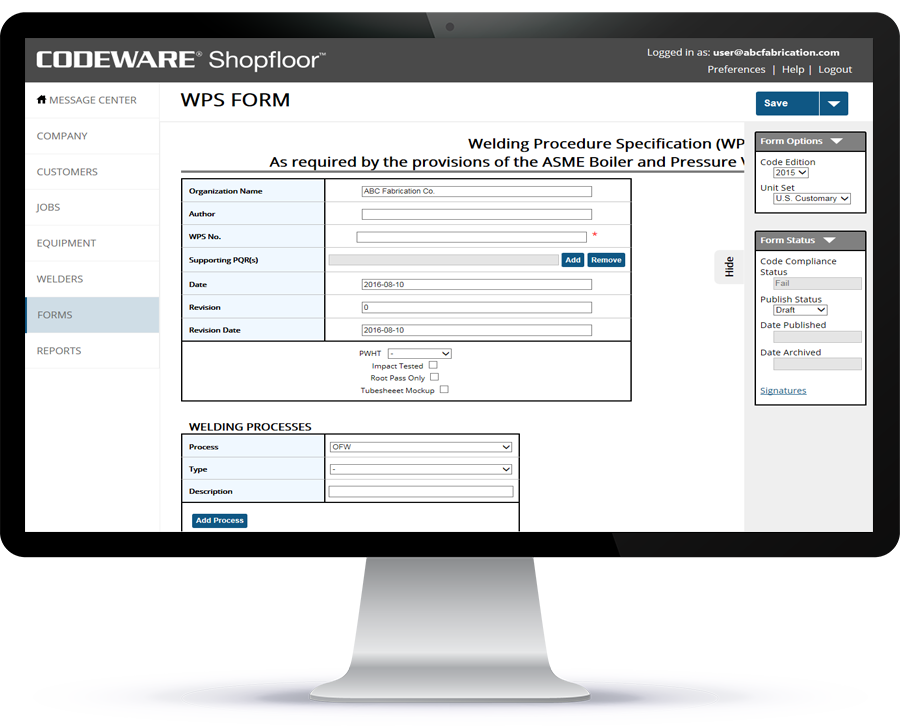

Manage ASME IX Weld Forms, Welders and Jobs

Shopfloor is an integrated solution that connects ASME IX weld forms to both pressure vessel design and drawings. Want to transition from paper or change out your existing welding software? We offer a Shopfloor weld procedure set-up service to input your existing forms and get you up and running quickly.

Just a Few of our Fabrication Clients

“We have been using COMPRESS since its inception. Les Bildy has developed a first rate product. We have found it very user friendly, and can’t imagine our company succeeding without it.”

“In our 20 plus years of using COMPRESS including the design, quotation and fabrication of in excess of 10,000 pressure vessels, we have come to rely on the accuracy and dependability we get each and every time.”