INSPECT Data Logger Integration

How much time would you save and how many errors would you avoid if you could access your data logger’s grids and thickness surveys directly from your Fitness-for-Service software? INSPECT’s data logger integration makes setting up and retrieving inspection grids from thickness gages fast and easy. INSPECT’s unique 3D flaw modeling and data logger integration simplify the API 579-1 flaw assessment workflow to:

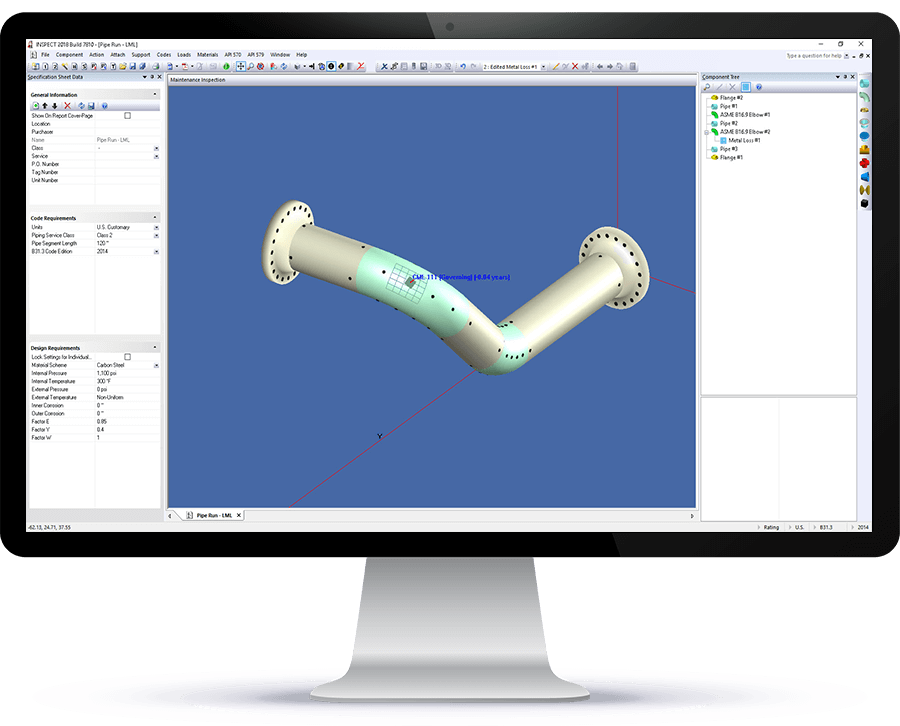

Data Logger and Flaw Assessment Demonstration Using INSPECT

In this brief video, Codeware’s General Manager, Matt Heilandt P. Eng., illustrates the use of INSPECT’s thickness gage integration by performing an API 579-1 Part 5 local metal loss flaw assessment on a pipe elbow.

INSPECT Featured Capabilities

Find Out More