| API 579-1/ASME® FFS-1 Calculations With Detailed Reports |

|

| Part 3 – Brittle Fracture, Levels 1 and 2, includes Minimum Safe Operating Temperature assessments and curves |

|

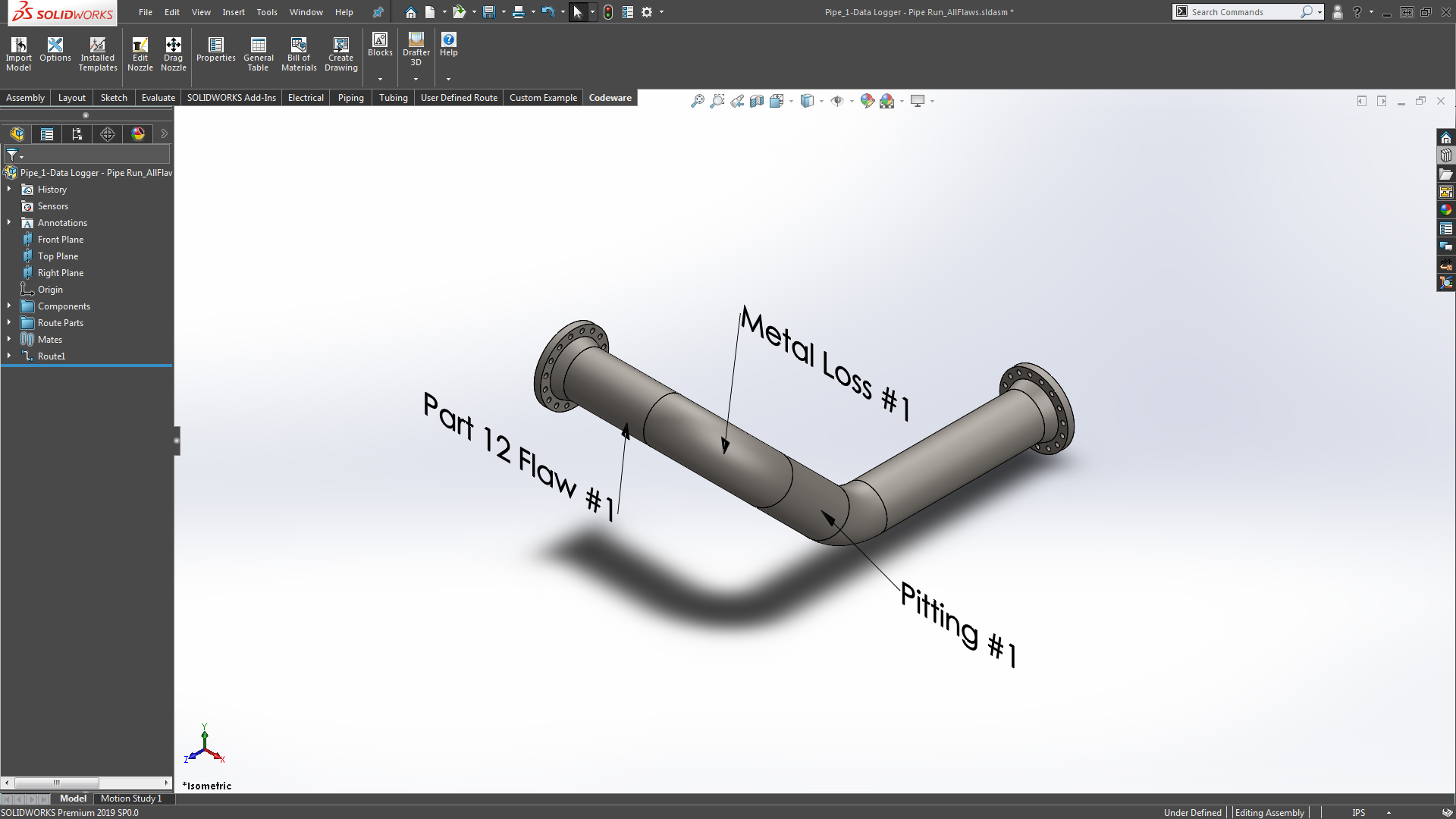

| Part 4 – General Metal Loss, Levels 1 and 2 |

|

| Part 5 – Local Metal Loss, Levels 1 and 2 (includes groove-like flaws) |

|

| Part 6 – Pitting Corrosion, Levels 1 and 2 |

|

| Supplemental loads for Part 5 and 6 |

|

| Combined Local Metal Loss and Pitting |

|

| Part 7 – Hydrogen Induced Cracking (HIC) and Hydrogen Blister assessments, Levels 1 and 2 |

|

| Part 8 – Out-Of-Roundness, both simplified Dmin/Dmax and multiple point Dmin/Dmax assessments |

|

| Part 9 – Crack-like Flaws, Levels 1 and 2 |

|

| Part 10 – Creep assessments, Levels 1 and 2 |

|

| Part 11 – Assessment of Fire Damage, Levels 1 and 2 |

|

| Part 12 – Dents, Gouges and Dent-Gouge Combinations, Levels 1 and 2 |

|

| Part 13 – Lamination assessments, Levels 1 and 2 |

|

| Part 14 – Fatigue assessments |

|

| Integrated 3D Inspection Data Management System (IDMS) |

|

| Automatic and manual inspection point (CML) placement |

|

| Attach images and related documentation to any CML |

|

| User defined CML data fields, as many as required, provide information tracking flexibility |

|

| Governing CML locations highlighted on 3D models |

|

| API 510, API 570 and API 653 calculations and reports |

|

| Minimum thickness calculations (tmin) |

|

| Determines inspection schedules (time based) |

|

| Quickly perform pressure vessel re-rating simulations |

|

| 3D plant modeling for Fixed Equipment Engineers |

|

| Vessel Wizard for fast vessel model creation |

|

| Intuitive user interface for quick piping layout creation |

|

| Ability to copy and paste piping components |

|

| Supporting ASME calculations and reports |

|

| ASME VIII-1 (Division 1) |

|

| ASME VIII-2 (Division 2), includes Class 1 and Class 2 vessels |

|

| ASME UHX heat exchanger calculations |

|

| Multiple ASME VIII Code Editions in one program (1995 – present) |

|

| Multiple ASME II-D Editions, including consideration of table notes (1995 – present) |

|

| API 570 and API RP 579/ASME FFS-1 piping tmin’s calculated using ASME B31.3 and ASME B31.4 rules |

|

| TEMA 7th, 8th, 9th & 10th Ed. heat exchanger calculations |

|

| NBIC R-1, R-2 Repair Forms |

|

| ASME A-1, A-2 Alteration Forms |

|

| Includes all COMPRESS features and options |

|

| Supports equipment design for new construction projects |

|

| Process piping inspection checklists with user-defined commentary |

|

| Associate API RP 970 Corrosion Control Documents with 3D process loops |

|

| Brittle fracture checks as recommended by The National Certified Pipe Welding Bureau (NCPWB) |

|

| Minimum pipe structural thickness check per API RP 574 |

|

| Short term, long term and user-defined corrosion rate trend analysis |

|

| Mechanical Integrity RAGAGEP comply with OSHA 1910.119(d)(3)(ii) and EPA Title 40 Part 68 |

|

| Tmin calculations use local CML joint efficiencies to extend vessel remaining life and inspection intervals |

|

| WRC-489 – Paragraph 4.2.8 Creep and Stress Rupture check |

|

| Documents undocumented pressure vessels |

|

| API 653 tank bottom patch plates (repair plates) |

|

| Exports piping showing flaw locations and types to SOLIDWORKS for fast creation of 3D PDF documents |

|

|

API-579 Part 4, 5 and 6 for API-653 Storage Tanks

|

|