Perform API 579-1 Part 13 Lamination Assessments With INSPECT

Laminations may be defined as a lack of internal fusion that occurred at the mill when the steel plate was rolled. Sub-surface laminations are typically encountered in older vessels and may have been present for years before detection. Finding laminations during a plant shutdown/inspection is often “one more thing” that needs to be added to a previously planned, often very tight, work schedule. INSPECT quickly models laminations and provides rapid results so you can make the necessary mediation decisions with confidence.

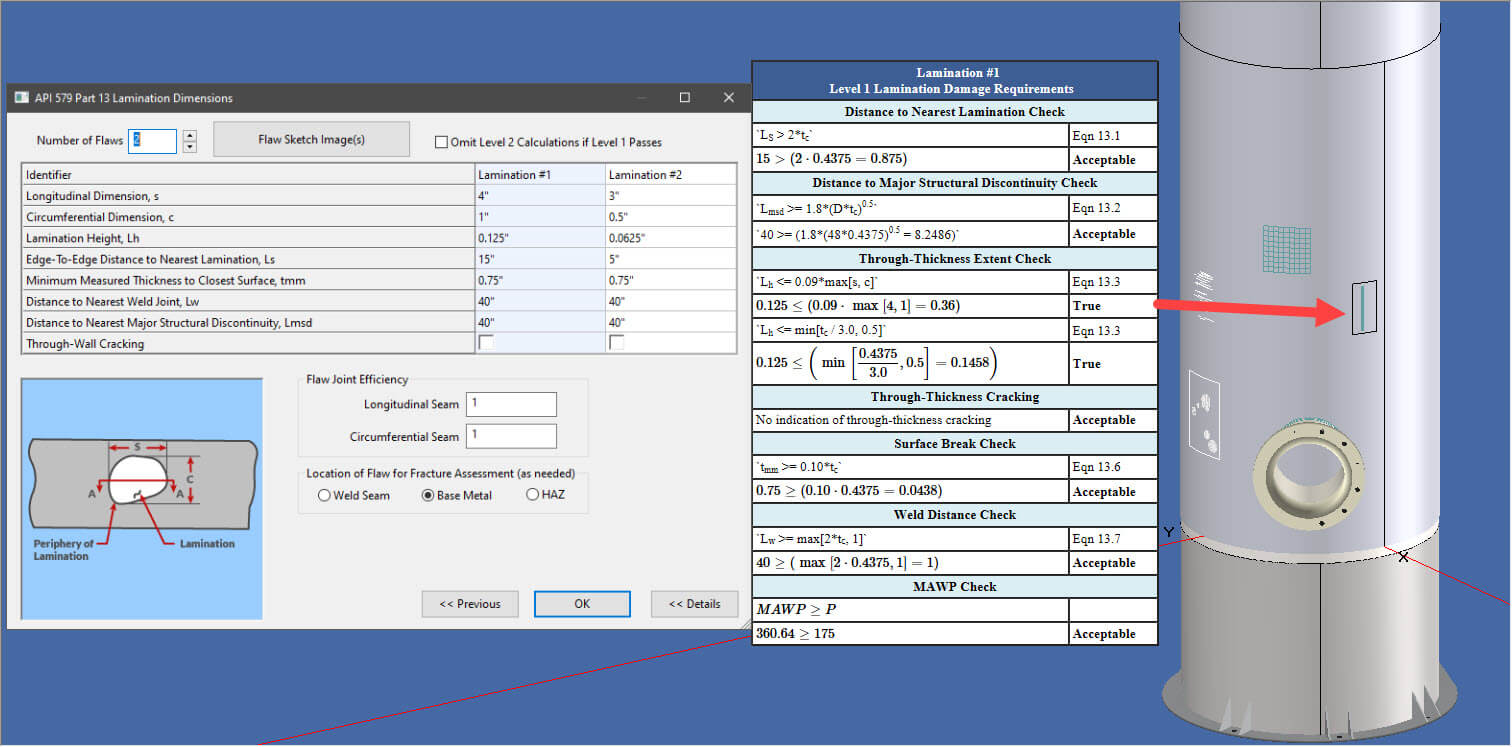

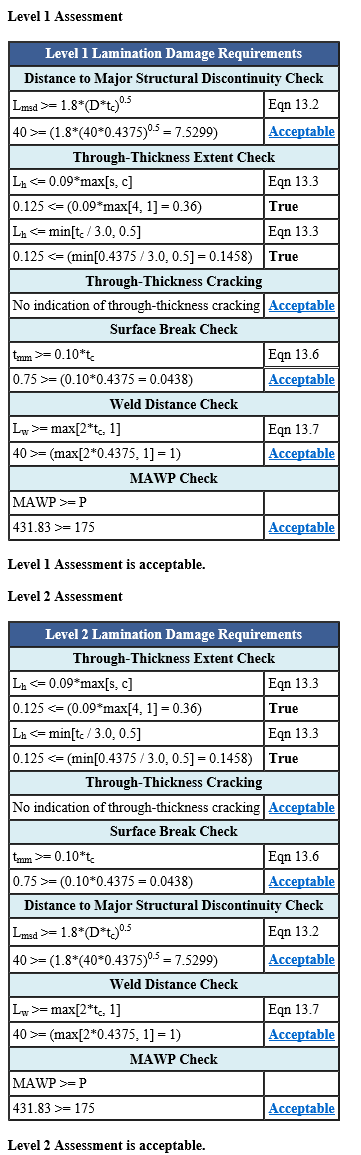

In INSPECT simply model the locations and descriptions of the laminations to be assessed. Interactive Level 1 results are then automatically shown while still in the Part 13 data entry dialog.

Laminations Shown on Vessel Models

3D representations of all flaws, including laminations, are presented by INSPECT as a reference. As is the case with all flaw types in INSPECT, multiple Laminations can be specified on one component (or vessel). These unique graphical features increase productivity and ensure factors including supplemental loads, nearby flaws and structural discontinuities are taken into account.