Finite Element Analysis in COMPRESS

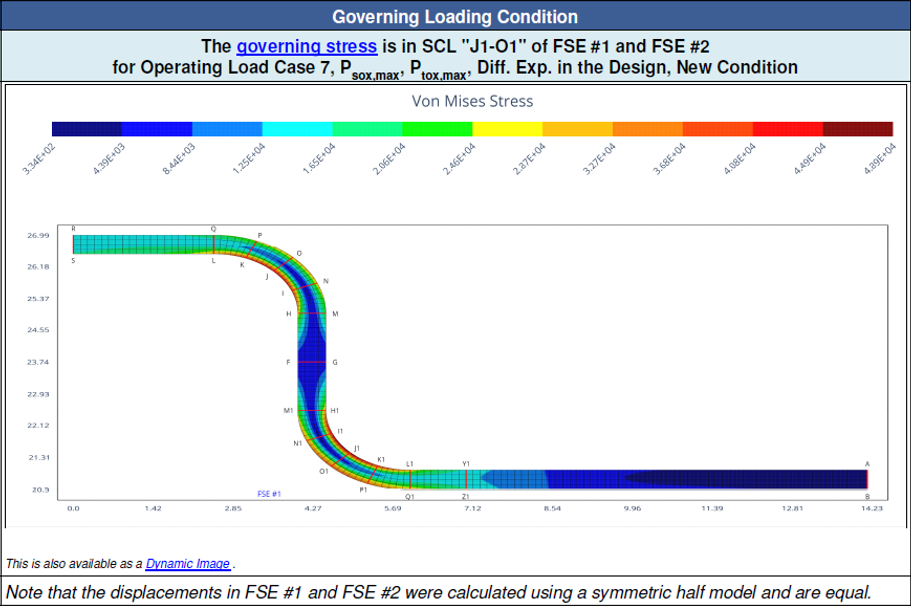

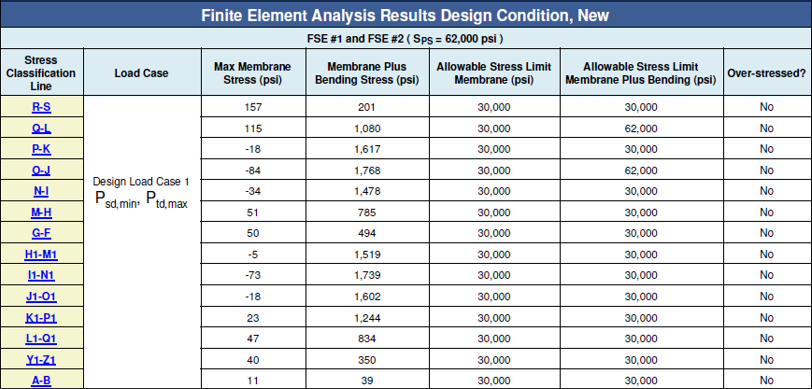

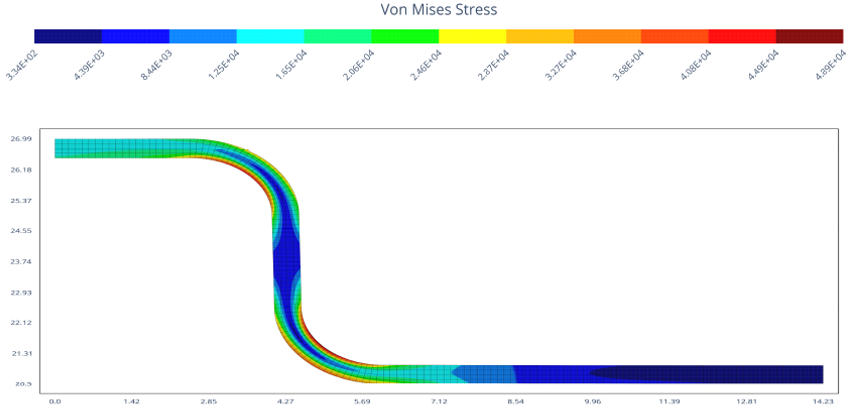

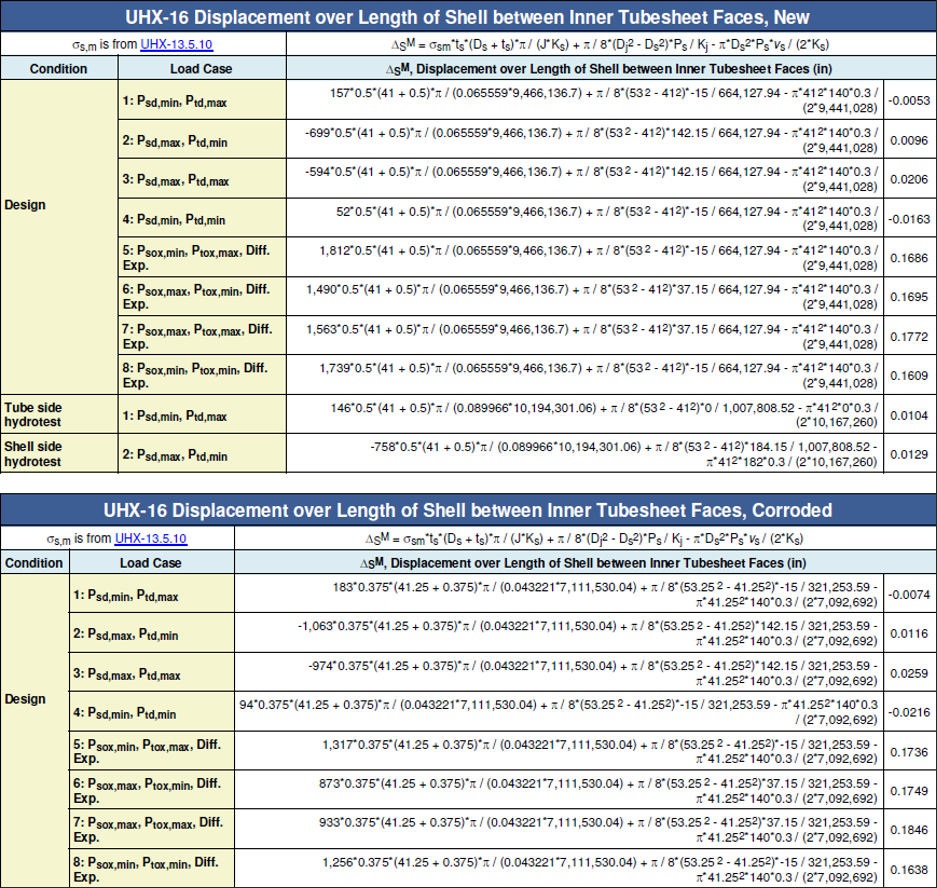

The COMPRESS heat exchanger option now includes built-in Finite Element Analysis (FEA) for TEMA Flanged and Flued Expansion joints. Developed from the ground up by Codeware, the FEA engine provides seamless integration with our COMPRESS and INSPECT platforms. Once the expansion joint is modeled, running FEA is a simple click of a button. All meshing, boundary conditions, and required load cases are run automatically. Our FEA engine takes full advantage of your hardware’s abilities which substantially reduces model runtime when compared to conventional general purpose FEA solutions.

COMPRESS Featured Capabilities

UG-28 rules for external pressure of 15psig and greater.

Find Out More