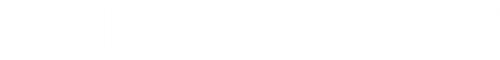

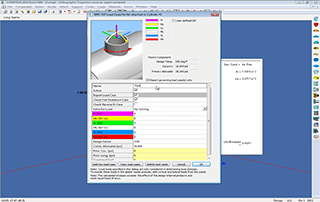

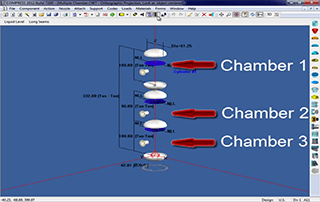

Check Nozzle Loads With WRC 537, WRC 107

Process piping imposes external loads on vessel and exchanger nozzles that must be accounted for (see ASME VIII-1, UG-22). Stresses on pressure vessel nozzles and attachments have historically been checked using the Welding Research Council Bulletin 107. WRC 537 was published in 2010 and was meant to update and replace the widely used WRC [...]

+1 (941) 927-2670 | sales@codeware.com