The Advantages of Locating Pressure Vessel Weld Seams

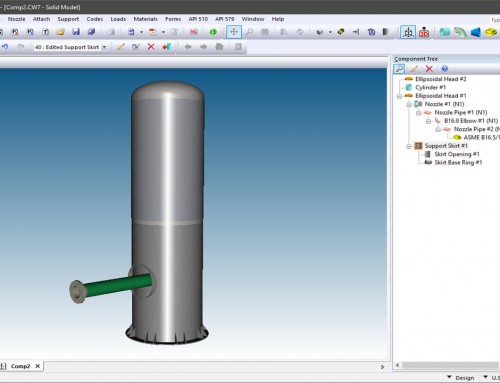

Although not required to perform basic (theoretical) ASME calculations, specifying weld seam locations when designing pressure vessels provides a number of practical advantages:

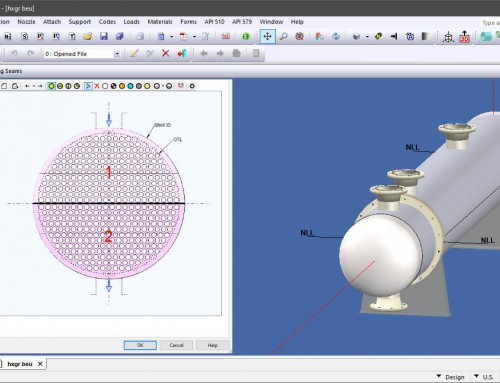

The COMPRESS\INSPECT shell seams feature also creates a shell roll-out sketch that is included in the seams report.

Shell seams are turned on by default for all new pressure vessels created in COMPRESS Build 6310 and later. To view seams on a design created in an earlier Build:

- Open the file in the most recent version of COMPRESS or INSPECT.

- Select Action > Set Mode Options > Defaults > Long Seams.

- Check “Show longitudinal seams on cylinders, transitions, skirts, and hemi heads”.

Pressure vessel weld seams is just one of the many features enjoyed by users of our suite of software products. To find out more email sales@codeware.com or call us at (941) 927-2670 and set up a software demonstration today.

Having trouble viewing this video?