Pressure Vessel Lifting and Rigging Analysis

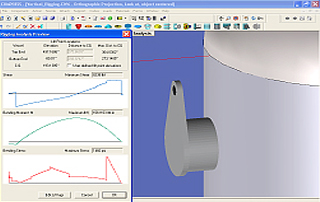

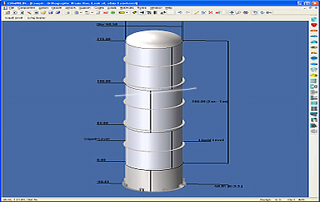

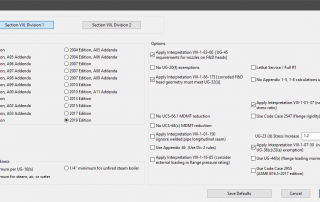

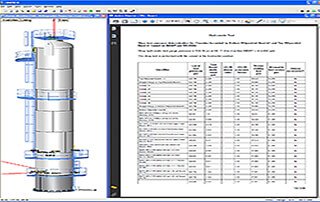

Lifting and Rigging Analysis What use is a highly engineered piece of pressure equipment if you can't safely get it off the rail car and stand it up? COMPRESS and INSPECT include an integrated solution to this complex task. When performing lifting and rigging analysis COMPRESS and INSPECT: Use an accurate weight [...]