Use these 5 tips to save time when designing vessels and exchangers with COMPRESS.

- Quickly navigate using the shortcut keys:

- Insert – Insert a component

- Delete – Delete a component

- F2 – Nozzle design

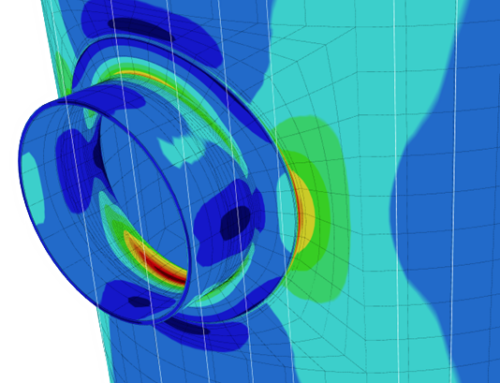

- Ctrl + F3 – Run FEA on nozzles

- F3 – Generate reports

- F4 – Edit a component

- F7 – Set mode options

- F8 – Set the datum

- Utilize the input calculator. COMPRESS automatically converts an input of 6’7″ to 79″. You can also enter data as basic mathematical expressions (1/16″ converts to 0.0625″).

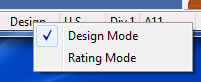

- Use the calculation mode best suited to your project. In design mode, COMPRESS selects thicknesses and ratings to meet ASME Code requirements. In rating mode, COMPRESS calculates the MAWP based on your specified thickness. To change modes quickly, right click the status bar:

- Customize component material lists by adding and removing ASME II-D materials (go to “Materials | ASME Materials”). Once user defined materials have been saved to the COMPRESS database, re-use them by selecting “User Defined” from the top of any material list.

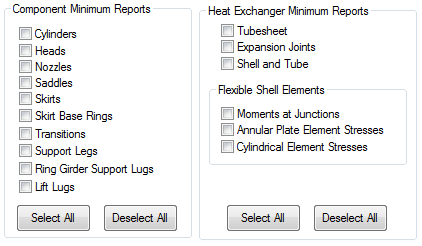

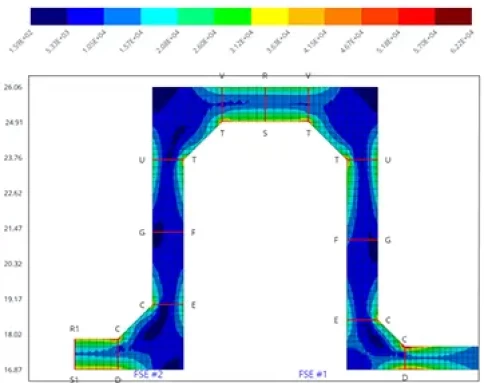

- Use component minimum reports to summarize information. Select “Action | Reports | Report Defaults” to specify which reports you would like shortened.