Advanced ASME Reports, Code Compliance, and Maintaining Nozzle Positions in COMPRESS

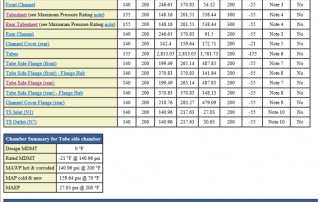

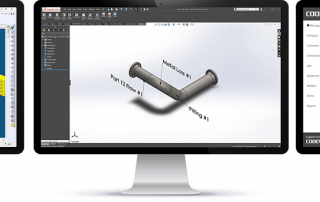

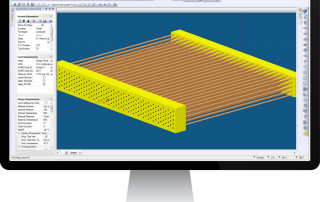

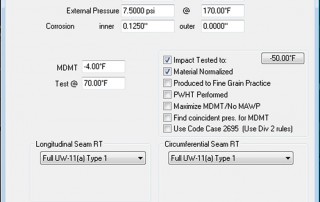

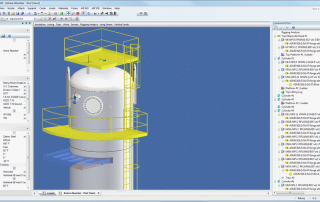

We're pleased to announce the release of COMPRESS 2020 Build 8000. New features include: Compliance with the 2019 Edition of the ASME Code Advanced Report Formatting for easier to read design reports Maintaining nozzle positions when adding or deleting components Please watch the video below to see these [...]