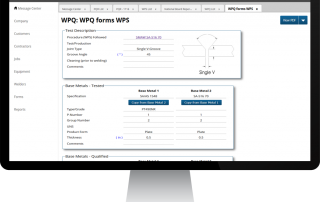

Shopfloor – Maintaining Welder Continuity

Maintaining Welder Procedure Qualifications (WPQ) Shopfloor simplifies the task of creating and tracking WPQ forms and maintaining welder qualifications (continuity). Shopfloor's weld log tracks continuity and helps prevent welder expirations and costly re-qualifications. This tutorial video shows you how to set up a new welder and use Shopfloor's WPQ management tools. Download [...]