Integrate COMPRESS With Autodesk Inventor

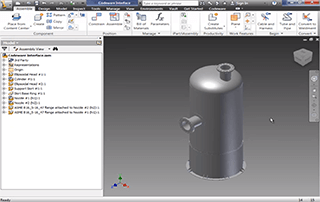

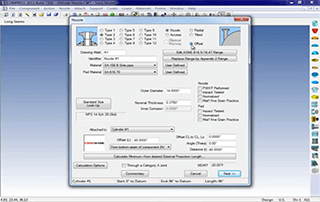

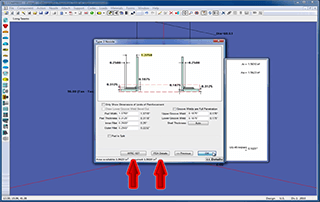

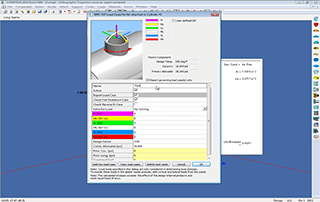

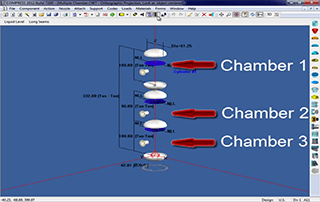

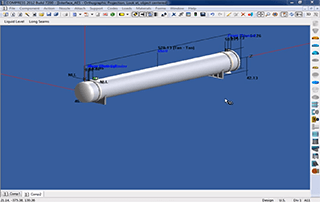

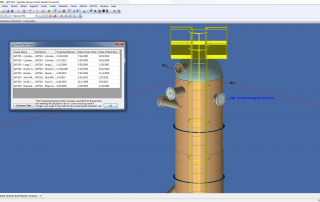

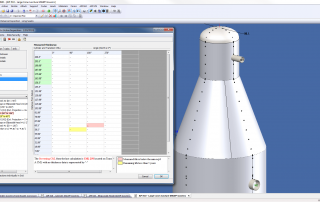

We are pleased to introduce the Codeware Interface®, an add-in for Autodesk® Inventor® or SOLIDWORKS®. The Codeware Interface add-in for Inventor imports your COMPRESS pressure vessel model and manages the associated data through iProperties. There is no additional charge for the Codeware Interface add-in provided that your company has current COMPRESS support. How [...]