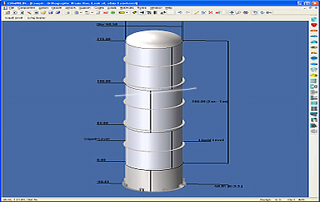

Openings in Support Skirts

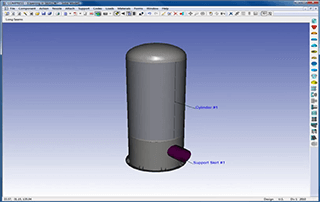

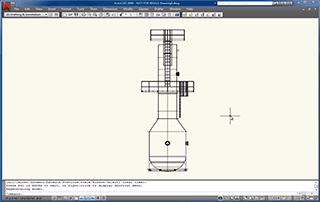

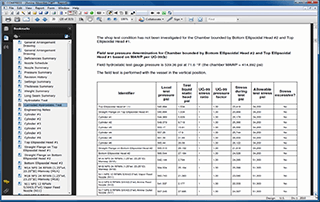

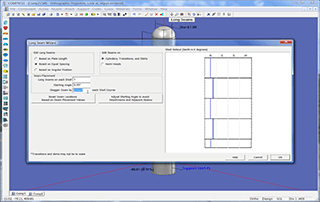

Support Skirt Openings Piping connections to vertical vessels often require additional piping and an opening cut out of the support skirt. COMPRESS includes the ability to specify and check the adequacy of this commonly encountered design detail. Circular pipe sleeves, internal projections, tilt angles, and skirt reinforcing pads can be considered. The ability [...]