Tube-to-Tubesheet Expansion in Shopfloor

Sealing tubes is an essential part of any shell-and-tube heat exchanger manufacturing process, and there are various considerations to make when determining the best tube-to-tubesheet expansion methods.

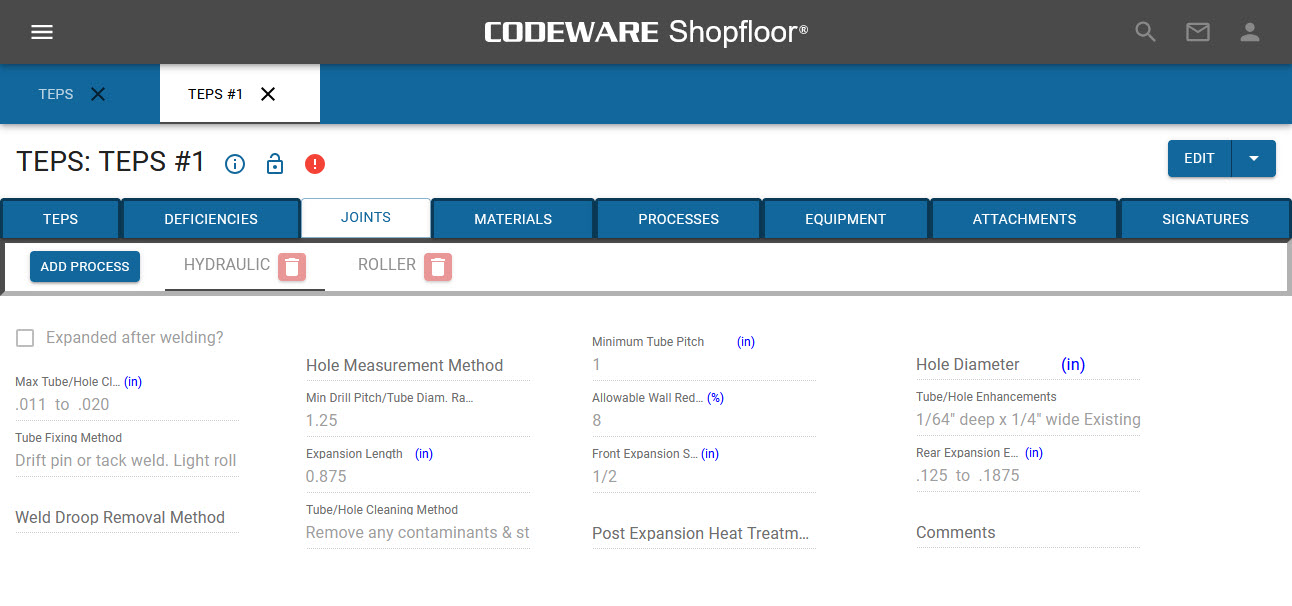

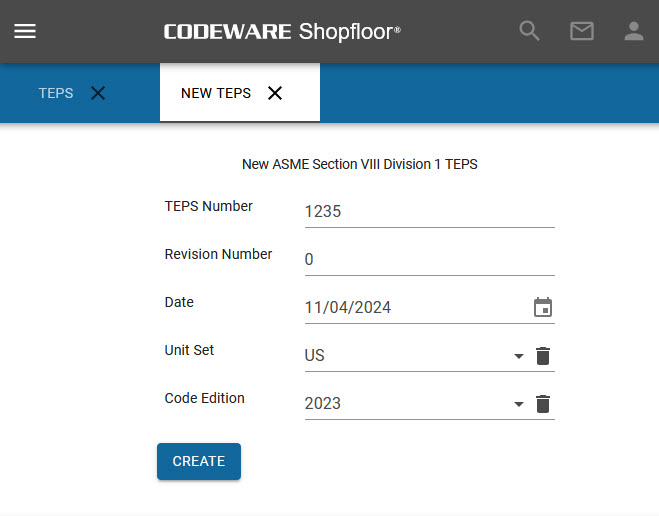

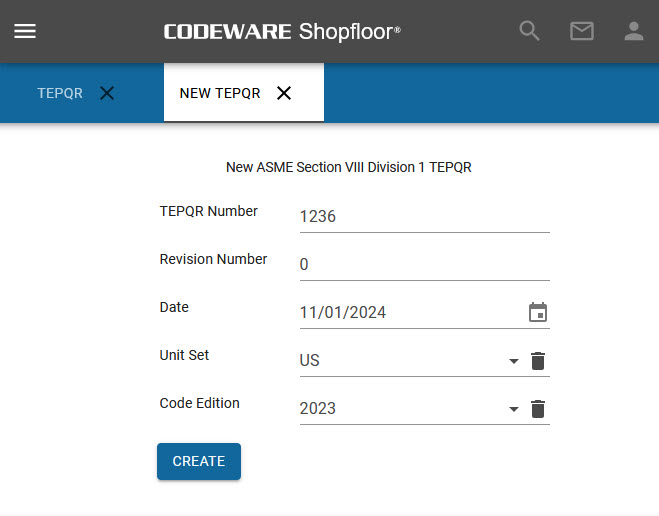

Shopfloor includes tube expanding procedures and qualifications from Nonmandatory Appendix HH of ASME VIII-1 which establishes the requirements for procedure specifications for expanded tube-to-tubesheet joints.

Compliance, Precision, Quality

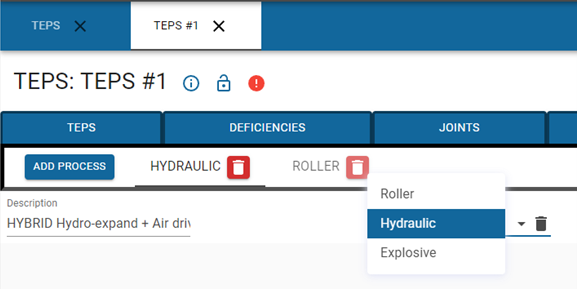

Ensure compliance, achieve precision, and improve quality using Shopfloor’s ASME VIII forms. The tube-to-tubesheet expansion forms available in Shopfloor include TEPSs and TEPQRs.

Optimal Tube-to-Tubesheet Expansion Methods

Shopfloor covers multiple methods of tube expansion:

+1 (941) 927-2670 | sales@codeware.com