Shopfloor

Welding Management Software

Streamline quality control, code compliance, and documentation in one easy-to-use cloud-based platform. Automatically check forms for ASME IX and AWS compliance, track welder continuity with proactive alerts, and generate project deliverables with just a few clicks. With interactive weld graphics, centralized data, and seamless integration with COMPRESS and INSPECT, Shopfloor helps fabricators save time, reduce errors, and stay audit-ready — all from any internet-connected device.

Why Shopfloor?

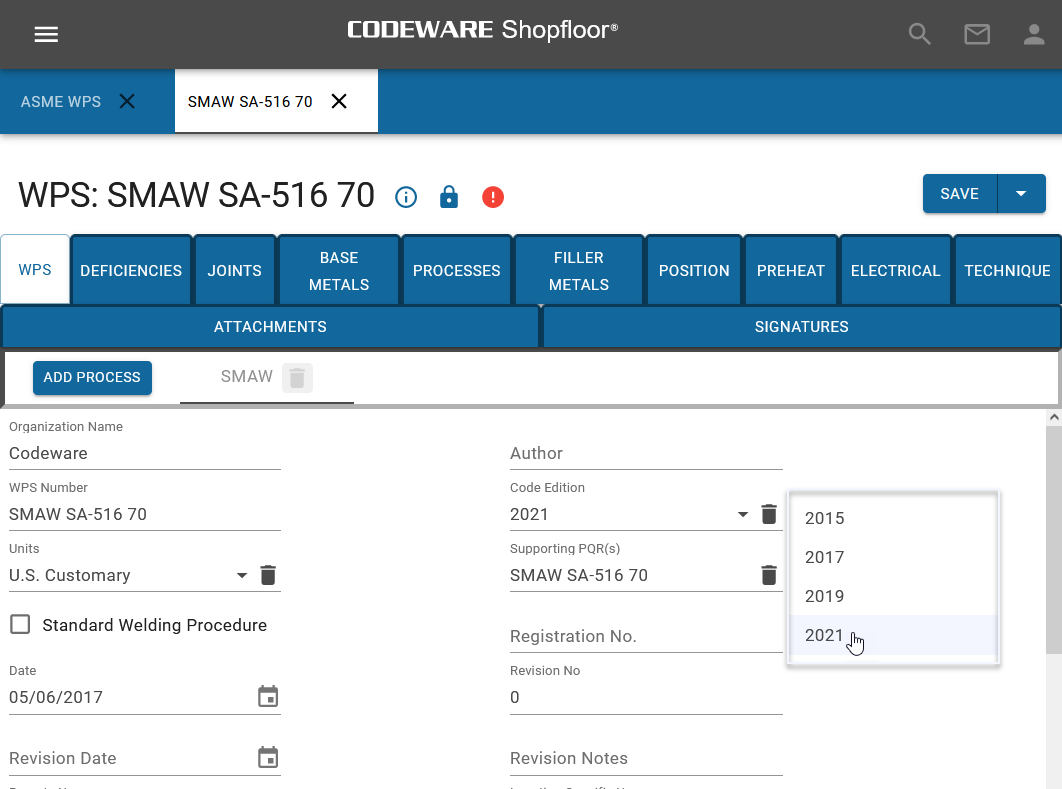

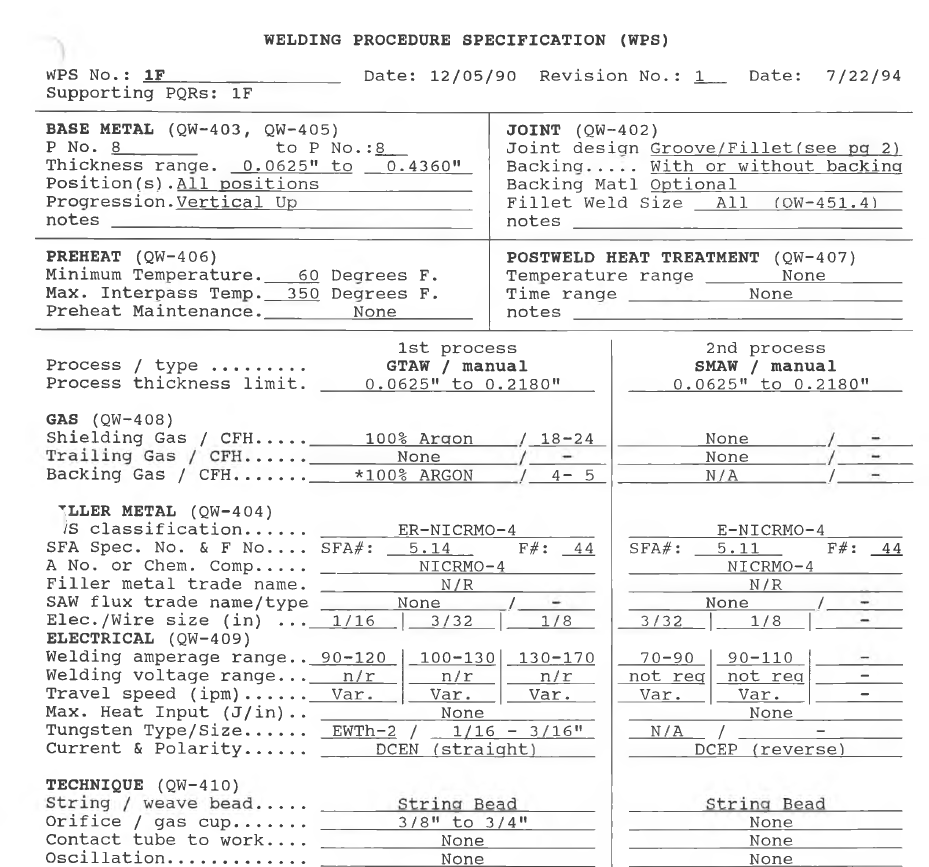

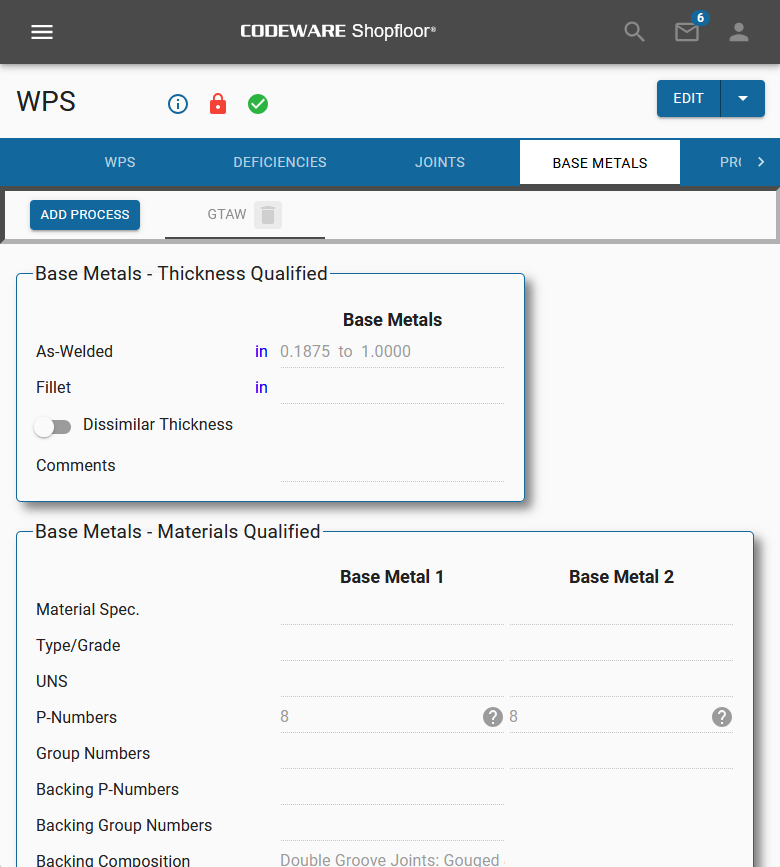

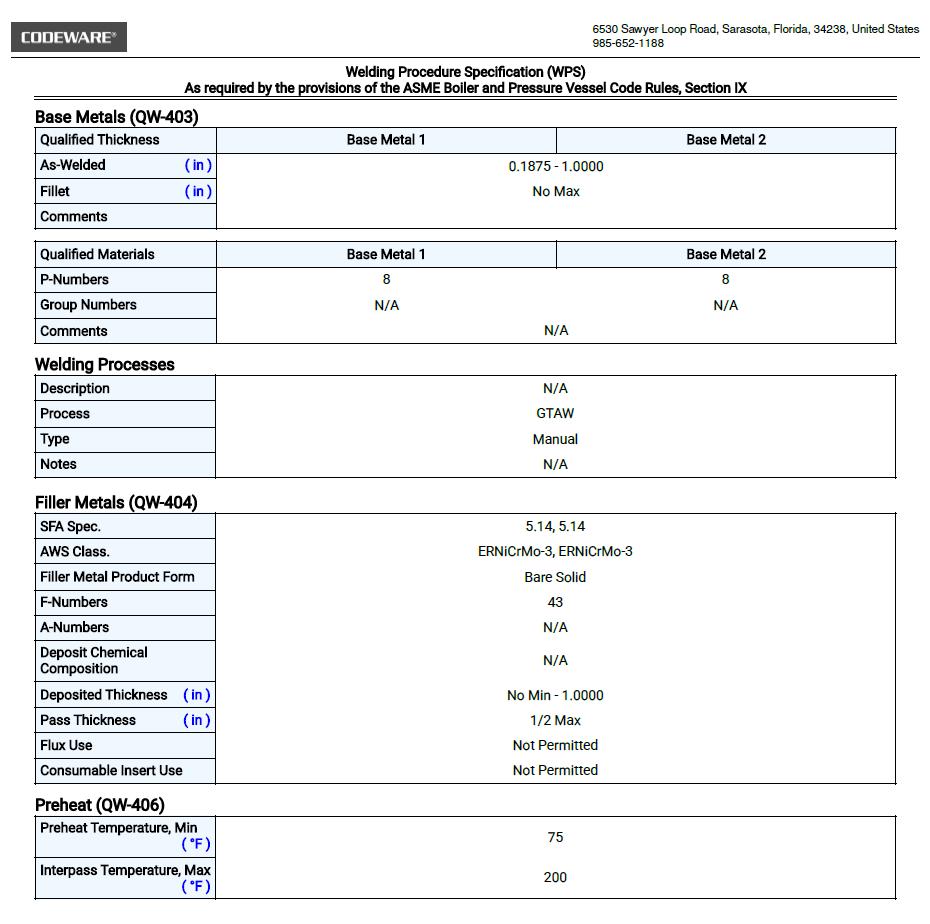

Easily Create Weld Procedures

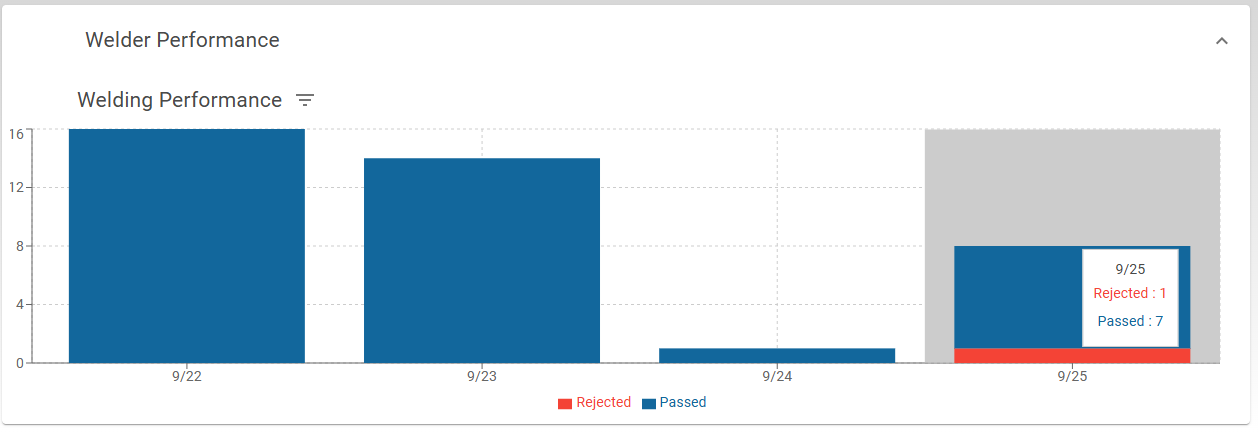

Rigorous Code Checks are performed in real-time to ensure your weld procedures comply with Code requirements. Full support for AWS prequalified welding procedures is provided.

With Shopfloor you can create and archive:

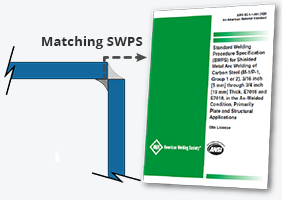

Does a Standard Welding Procedure apply?

Developing and testing new welding procedures is costly and time consuming. The American Welding Society (AWS) has created a number of inexpensive Standard Welding Procedures (SWPS) to address this.

Codeware has partnered with the AWS to quickly answer this question. With our exclusive AWS LookUp App you can:

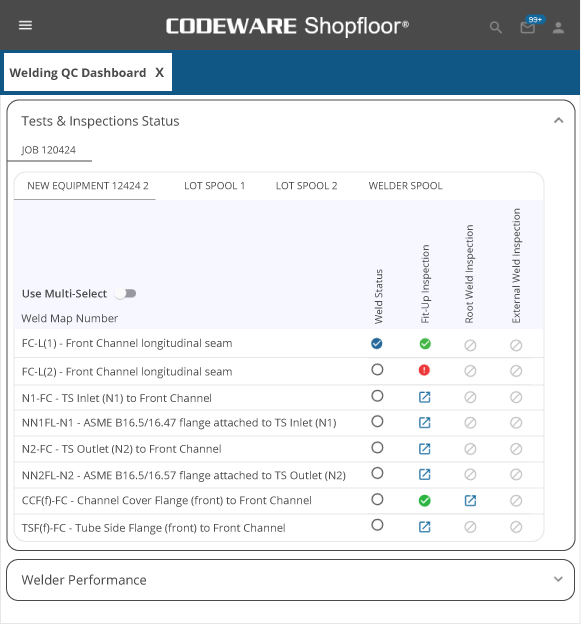

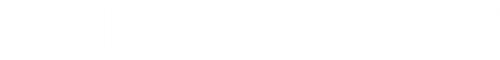

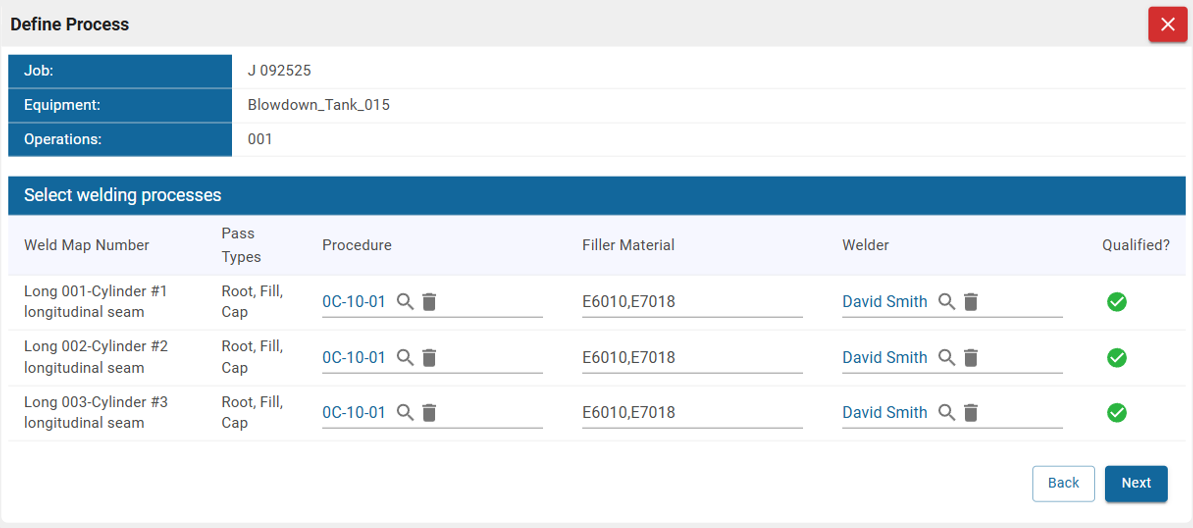

Equip Your Team With a Clear, Centralized View of Welding Quality Control

Stop digging through spreadsheets, emails, and PDFs. The Welding QC Dashboard gives your team a clear, centralized view of welding quality control – so you can catch issues early, stay audit-ready, and keep projects moving.

With Shopfloor’s Welding QC Dashboard, you can instantly monitor the status of welds across all active jobs – including pass/fail rates, inspection statuses, and schedules. It’s designed for welding supervisors, QC managers, and compliance officers.

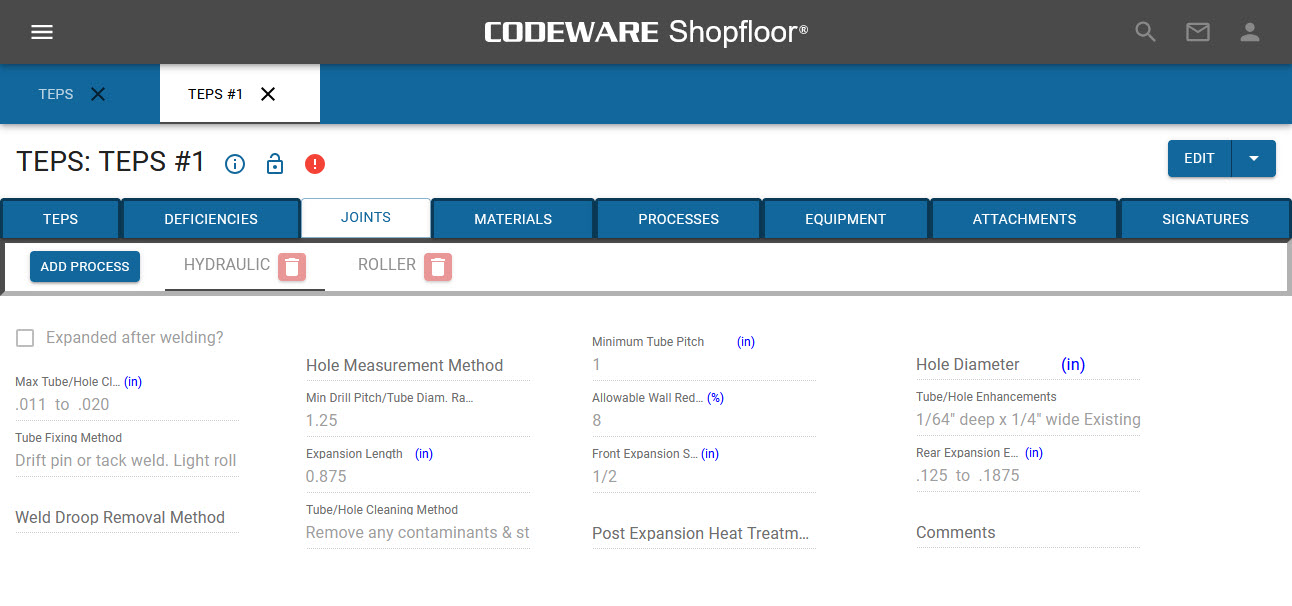

Stay Organized, Stay Standardized

Shopfloor is easy to learn and simple to navigate. Quickly find what you’re looking for with the platform’s powerful search functionality. Organize jobs by location, create the required welding procedures and forms, and track welder continuity.

Prequalified Welding Procedures (WPS)

Shopfloor supports and validates welding procedure creation according to the latest editions of the AWS Code, ensuring clarity and completeness. Organizations utilizing Shopfloor to prepare welding procedures realize the following benefits:

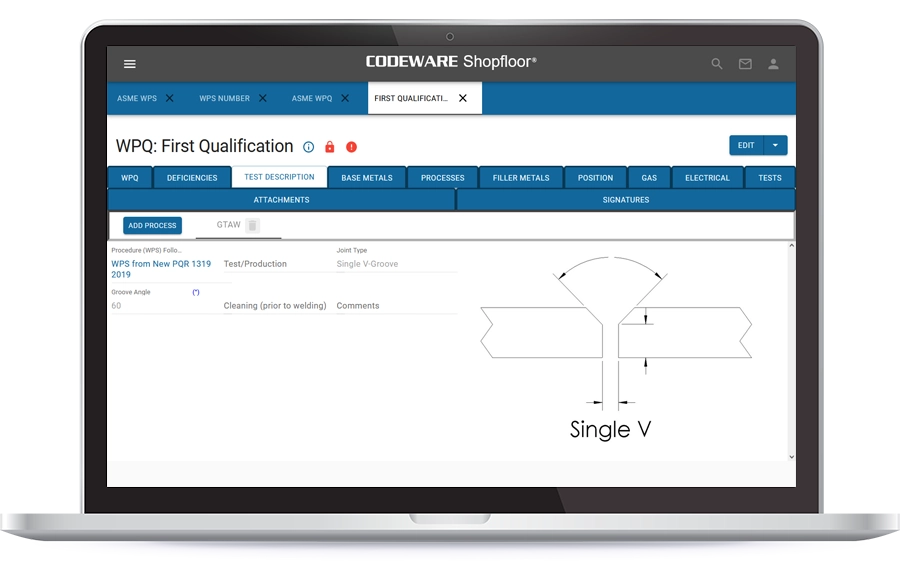

Maintaining Welder Procedure Qualifications (WPQ)

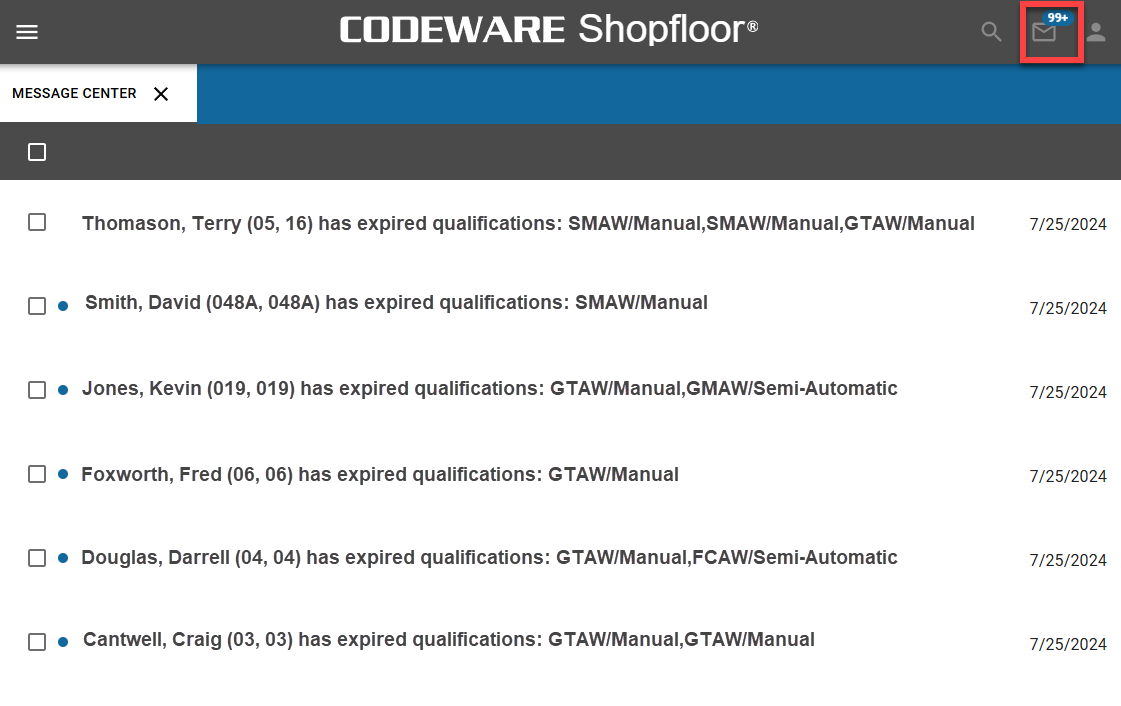

Shopfloor simplifies the task of creating and tracking WPQ forms and maintaining welder qualifications (continuity). Shopfloor’s weld log tracks continuity and helps prevent welder expirations and costly re-qualifications. Shopfloor makes tracking welders easy with:

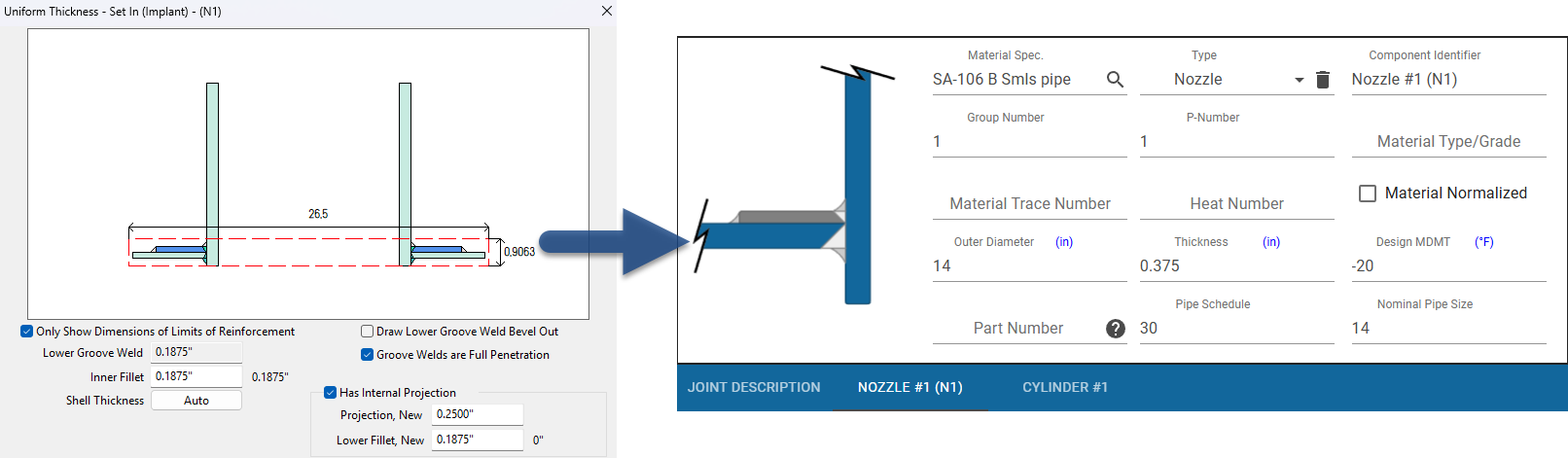

Design with COMPRESS, Manage with Shopfloor

Shopfloor is a native cloud-based ASME IX project management system. It works with COMPRESS and INSPECT to track welder continuity, perform Code checks and quickly determine if you’ll need to qualify additional weld procedures and/or welders.

Free Setup Service

Our setup service takes the hassle out of upgrading your legacy welding system to Shopfloor.

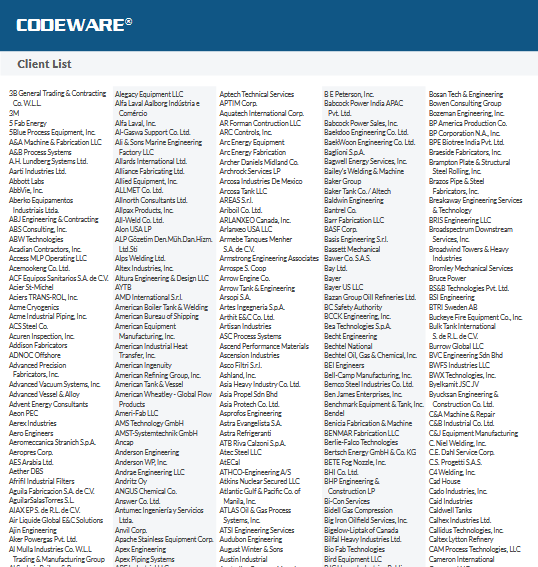

Increase Your Capabilities With Shopfloor

American Welding Society (AWS) Partnership

Exclusive Technical Partner

The American Welding Society (AWS) selected Codeware as the exclusive developer of its official certification management application for welding professionals. WeldCertPro, the digital platform for QC47 compliance and welder credential management, is built on the Shopfloor platform.

AWS Standard Welding Procedures

Codeware and the American Welding Society have partnered to distribute AWS Standard Welding Procedure Specifications (SWPS) to end-users and welders. Find and purchase the right AWS B2.1 Standard Welding Procedure for your job through Codeware’s advanced AWS LookUp App. If you are a Shopfloor customer, SWPSs purchased through the app will automatically be added to your Shopfloor account.

Unlimited Team Access – Get Started Today

Provide your team with as much or as little access to your welding platform as you’d like. All employees tracked by Shopfloor can be assigned login credentials and individual administrator-defined permissions. Because Shopfloor is cloud-based – it does not require Microsoft Remote Desktop to function – there’s nothing to install. Your valuable information is protected from threats like hard disk crashes and ransomware.

+1 (941) 927-2670 | sales@codeware.com