Transferring Thickness Grids Between Excel and INSPECT

Another useful feature of INSPECT is its ability to export\import thickness inspection grids to\from Excel. This streamlines the process of setting up thickness inspection points (CML’s) and improves coordination between Engineers and Inspectors. The INSPECT work flow eliminates manual data entry as copying and pasting data back and forth is not required. It also reduces errors and confusion because the Engineer and the Inspector are always working with the same data.

Transferring Thickness Measurement Grids (CML’s) To\From Excel

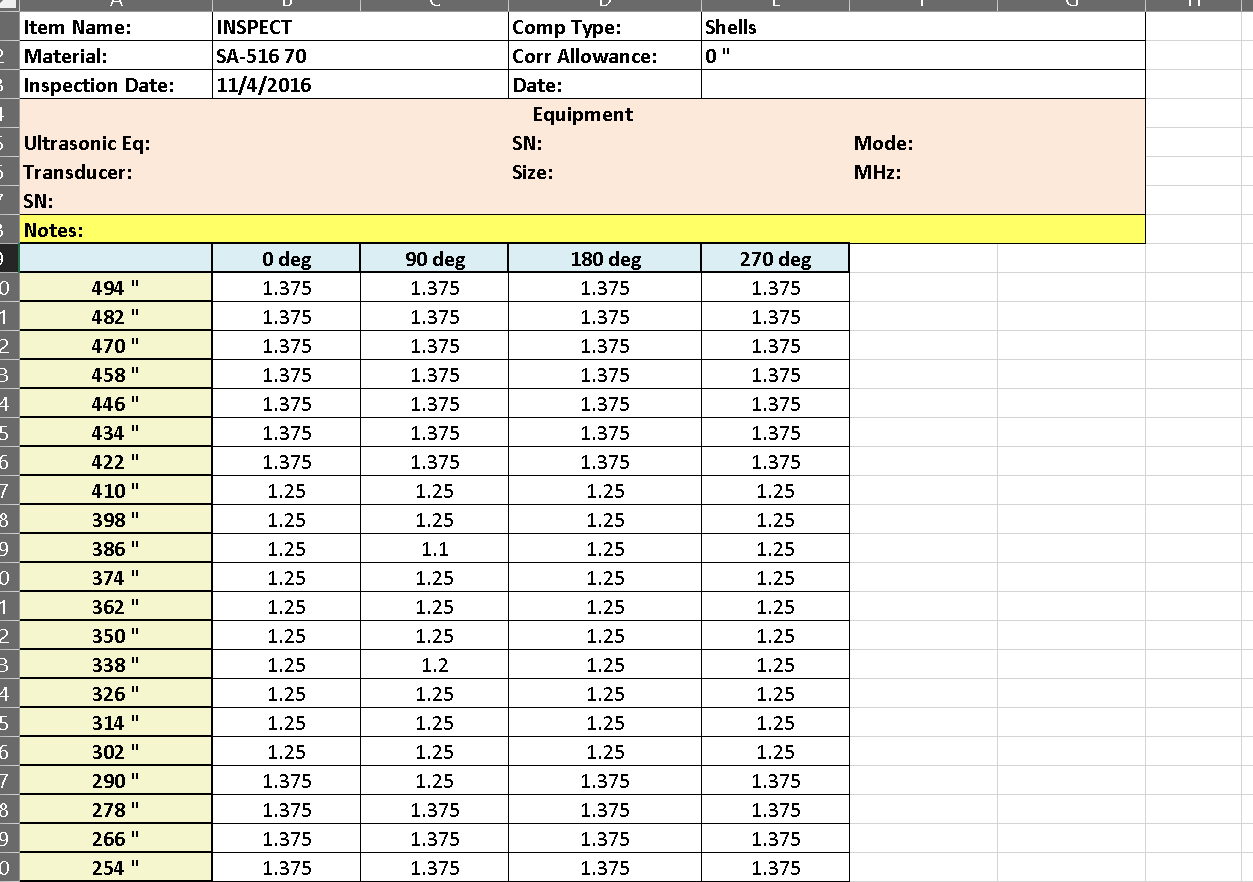

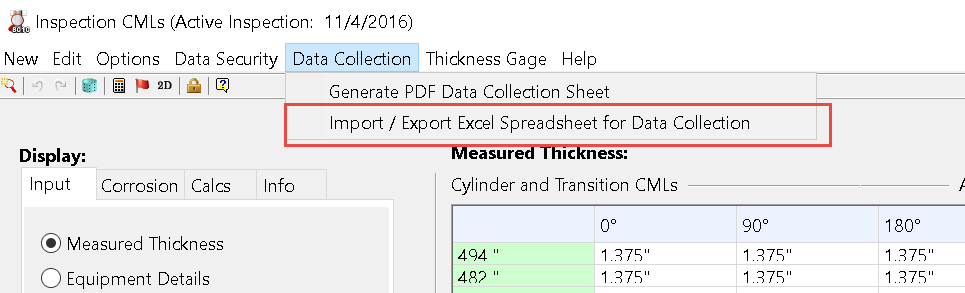

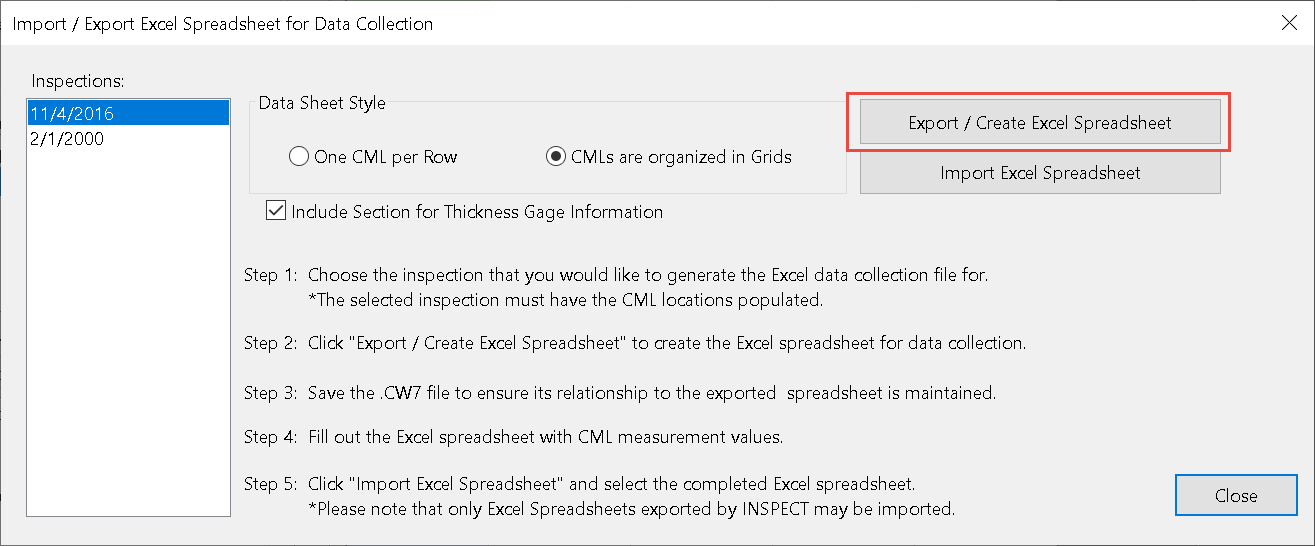

Using INSPECT, the Engineer first specifies the measurement locations on the equipment 3D model. This grid is then exported as an Excel spreadsheet. The measurements are then entered into Excel and sent back to be imported directly back into INSPECT for analysis.

The INSPECT workflow collects thickness inspection data in three easy steps: