Having trouble viewing this video?

Stacked Vessel Design Using COMPRESS

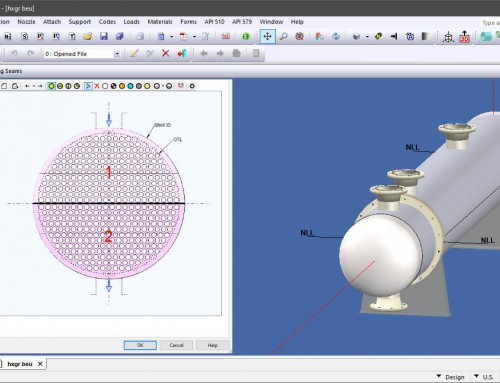

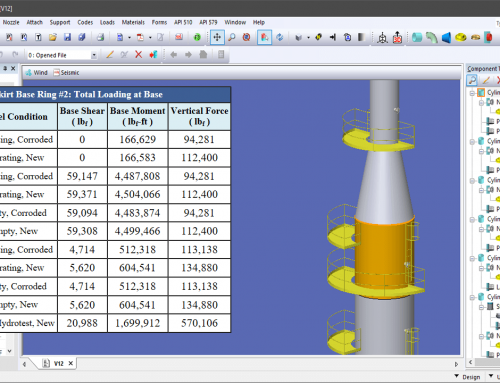

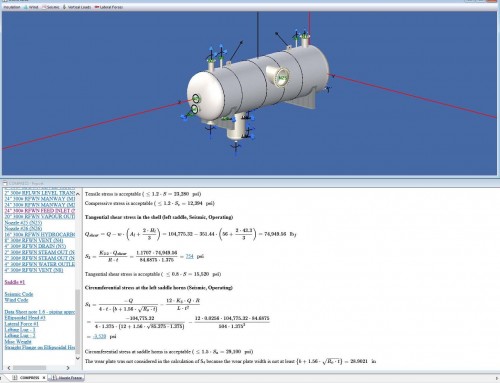

Certain industrial processes require pressure vessels to be built with multiple chambers operating under different design conditions. COMPRESS and INSPECT both support multiple pressure chamber, stacked vessel designs. Benefits of using this feature include:

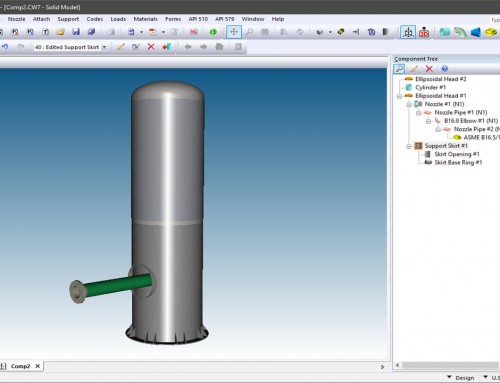

How to Model A Multiple Chamber Stacked Vessel

- Specify either an internal head (check box on head dialog) or an intermediate skirt.

- Establish the chamber’s operating conditions. Add liquid levels, nozzles and other attachments.

- Press F3 to run the code calculations. View each chamber’s MAWP in the Pressure Summary report.