Save Time With Design Mode

The COMPRESS Design Mode feature saves time by eliminating the manual iterations that would otherwise be required when designing pressure vessels. Design Mode takes your input data and selects component sizes, thicknesses and ratings based on ASME® Code requirements. It is usually used when designing new equipment as it is typically more efficient than Rating (Analysis) Mode. For post construction calculations on existing equipment, COMPRESS also features a Rating Mode. You can switch between Design and Rating Modes in COMPRESS at any time.

Consider what adding or changing the liquid level does to a pressure vessel’s design. It alters the supported weight, changes the static head acting on components below the liquid level and affects the equipment’s natural frequency i.e. how it responds to seismic and wind loads. Design Mode automatically tracks these interactions throughout the vessel’s design and enforces ASME Code compliance.

In Design Mode component required and nominal thicknesses are re-evaluated during the modeling process and updated as necessary to reflect all ASME Code dependencies. This is done because most components including heads, shells, nozzles, vacuum stiffeners and supports are dependent on each other and generally cannot be sized in isolation.

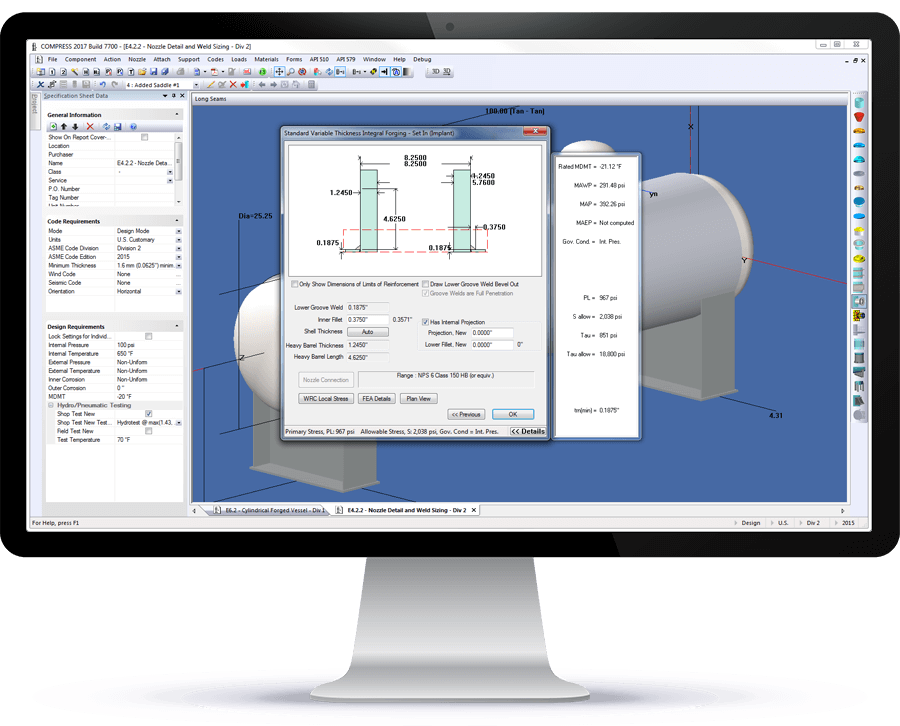

Guidance is provided while creating or editing pressure vessel components. For example, design mode includes interactive nozzle detailing that meets UG-37 reinforcement, UG-45 minimum thickness and UW-16 weld sizing requirements.

Optimum shell thicknesses are automatically selected along the height of the tower\vertical vessel based on combined loads and deflection limits.

Design mode automatically limits tower deflection per end user’s design specifications.

The vessel’s minimum design metal temperature (MDMT) is determined per the rules of UCS-66 or UHA-51 as appropriate.

Warnings and good engineering practice reminders are presented as appropriate.

COMPRESS Pressure Vessel Design Highlights

UG-28 rules for external pressure of 15psig and greater.

Request More Information

To see how COMPRESS can benefit your organization we invite you to contact us today.