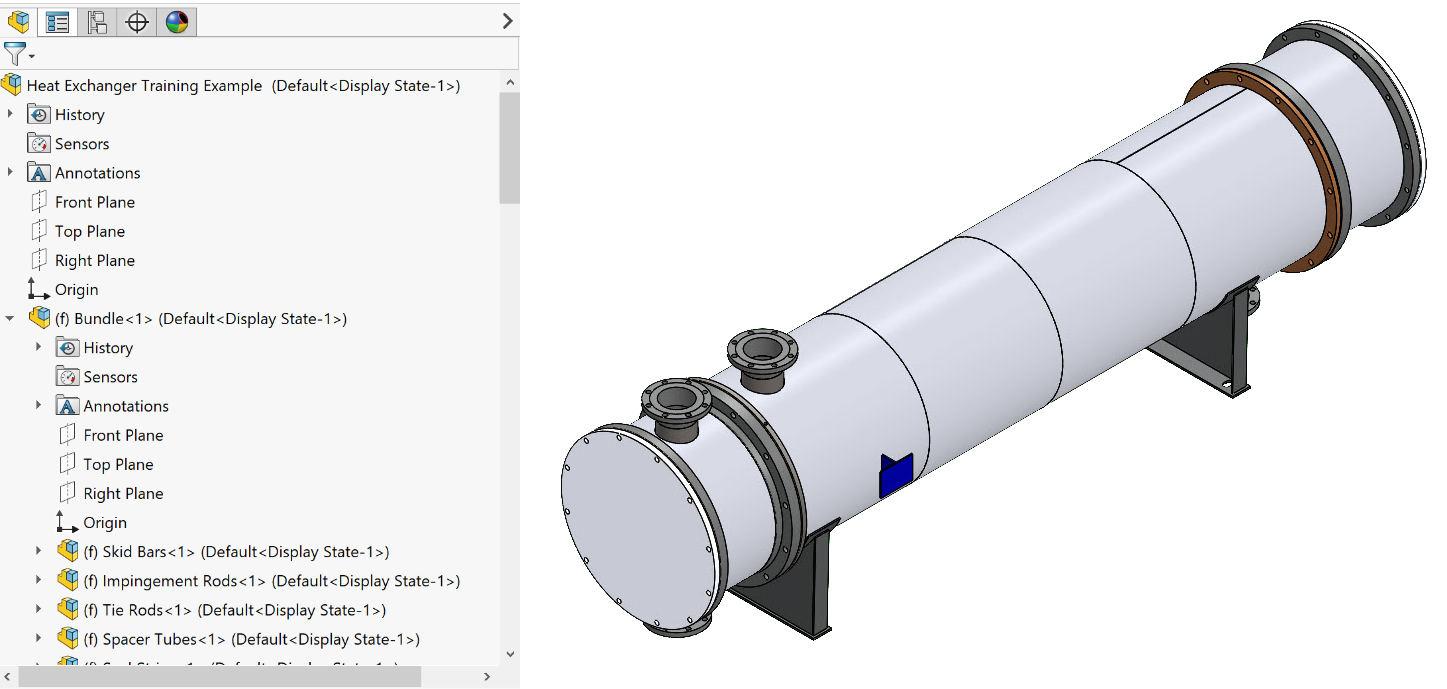

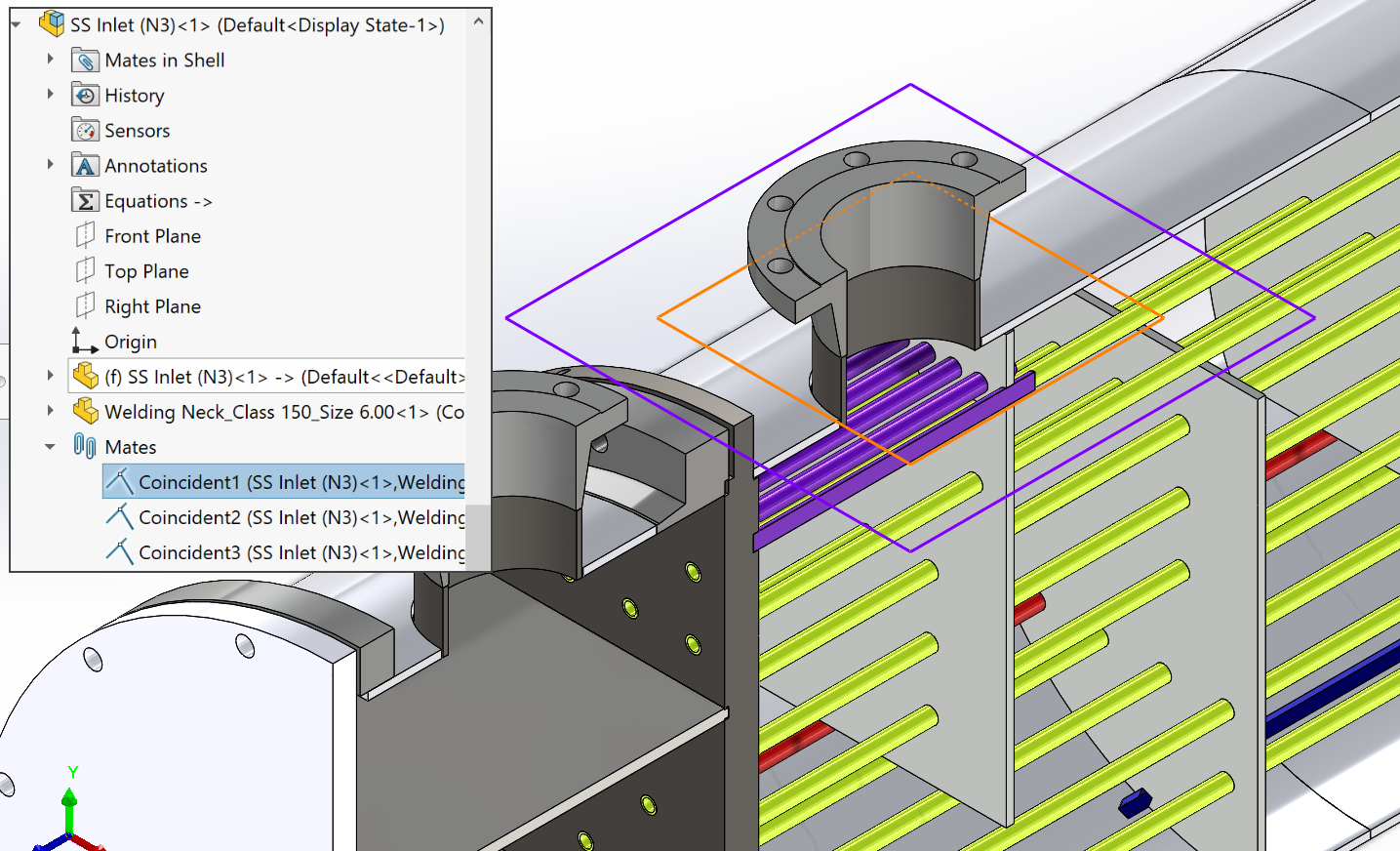

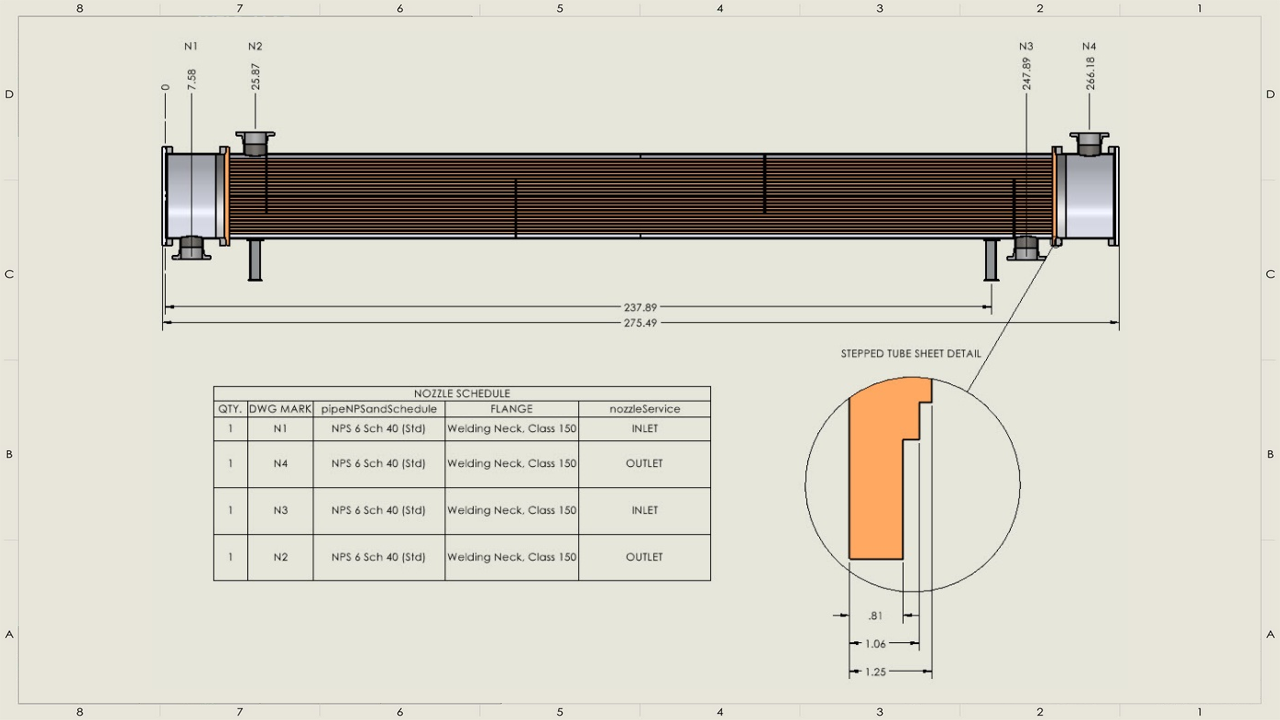

Sheet Metal and Mates

Competing software may claim to support SOLIDWORKS but before you decide ask if their models support SOLIDWORKS operations like Sheet Metal or Mates. Key features like these are required if you want to take full advantage of the time saving power of the SOLIDWORKS platform.

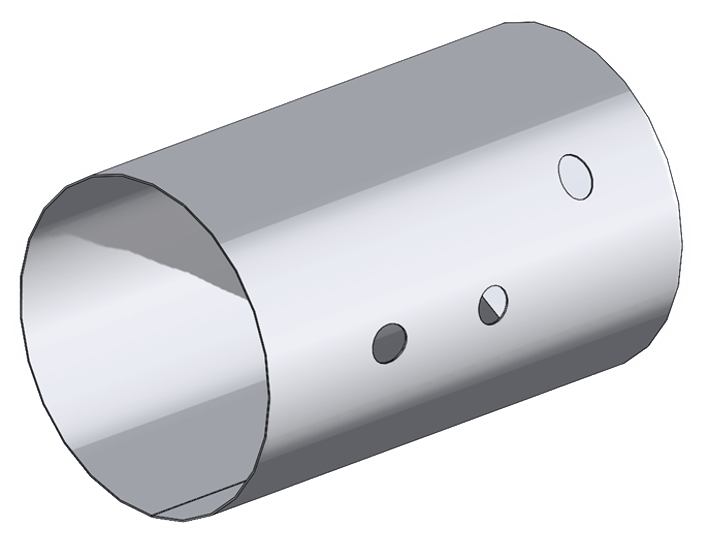

CWI makes use of the SOLIDWORKS sheet metal feature to automatically create flat (roll out) patterns