Interactive Vacuum Ring Placement

Another option COMPRESS provides is a drag-and-drop (Quick Design Mode) option for vacuum ring placement. By utilizing this feature, you can move the rings and quickly see how the external pressure rating changes. This makes it easy to find the optimal ring placement. Based on the desired ring positions, COMPRESS then selects a suitable ring cross section for you automatically.

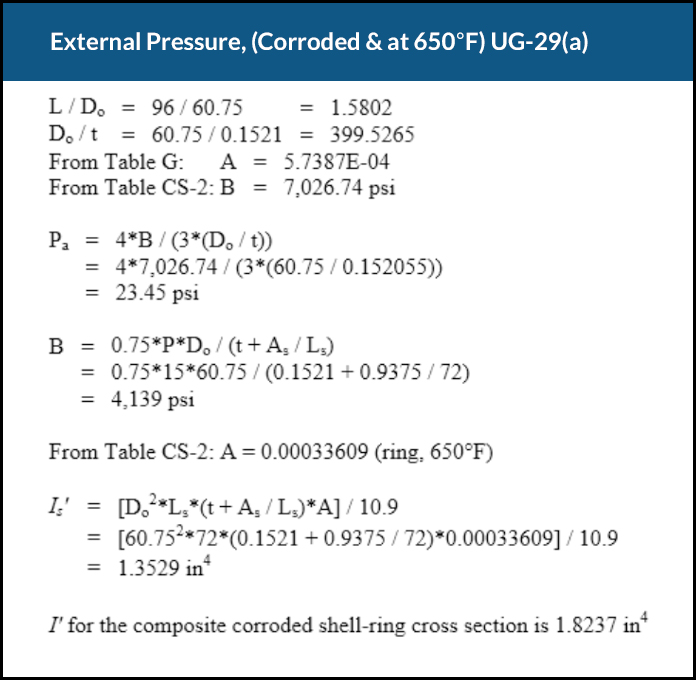

Stiffening Ring Calculations (UG-29)

When designing a pressure vessel for both internal and external pressure, one approach is to reduce the unsupported length until external pressure no longer governs. For vessels subject to external pressure only, it is often more economical to add intermediate lines of support than to increase thickness. In either case, adding strategically placed lines of support is the solution. Code paragraph UG-29 addresses the structural requirements for these lines of support (stiffening rings).

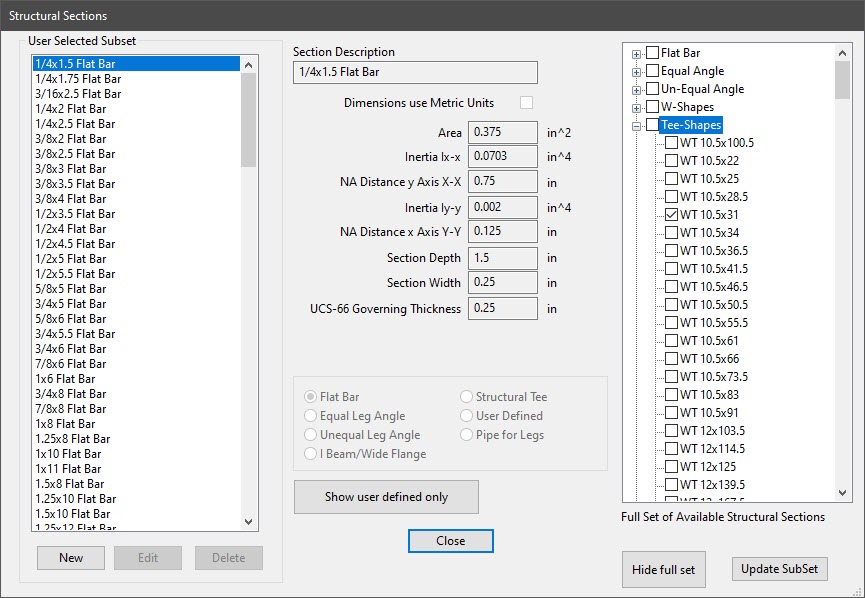

In design mode, COMPRESS will automatically select the minimum vacuum ring size required to meet UG-29 inertia requirements. Rings are selected by referring to the built-in, user definable, structures database. This eliminates the need to go through a structures list and manually choose the correct type and cross section.

Selecting Stiffening Rings

COMPRESS includes a large library of common structural shapes that can be used as stiffening rings. Users also have the option to add or remove shapes as desired. Adding shapes makes them available to the COMPRESS automatic selection routines while removing them does the reverse.

User-defined structures of any cross section can also be added.