Carbon Steel Materials and Unexpected Brittle Fracture

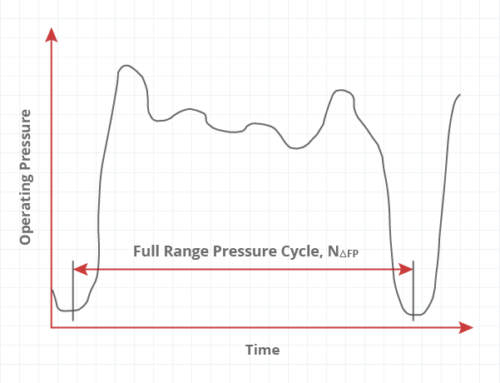

It’s been a while since I posted anything so I thought I would touch on an issue that recently came to my attention. Today’s blog entry deals with certain carbon steel materials and unexpected brittle fracture. We all know all materials are not created exactly the same. There will be slight differences in the material composition when the steel is made. This has been true for a long time so why are we seeing failures (many occurring during hydrotest) now with commonly used materials?

I often see vessel components such as flanges, nozzle necks and main chambers made from SA-105, SA-53 or SA-106B Pipe. The ASME Code usually exempts these materials from impact testing down to -20F with some exceptions. As summarized in the articles referenced below, brittle fractures have been experienced at temperatures considerably warmer than -20F despite the fact that the material met the applicable material specification. Why’s that? Well, let’s have a closer look at the material composition in the specification itself. I’m not going to get into all the details here but to get to the heart of the matter Manganese is used in making carbon steel to improve strength and toughness. Great, so what’s the problem? Manganese is expensive so some steel mills have been reducing the amount of Manganese used and adding other elements instead. While this substitution provides conformance with the material specification it reduces the toughness of the steel at lower temperatures to the point where the Code’s -20F exemption may be un-conservative.

So what can we do? If you are ordering material for a new job or have this material in use already here are some suggested ways forward:

For new construction jobs:

- Order your material impacted tested. You can easily specify this in COMPRESS or INSPECT by checking the option ‘Impact Tested’.

or - Specify the material composition to have a minimum Mn:C ratio of 5, and a grain size of 7 or finer for SA-105 flanges from your material supplier.

For existing equipment:

- Look into PMI (Positive Material Identification) devices. This will tell you exactly what composition you have. For cases where the Mn:C ratio is less than < 5 proceed to step B).

- Create user defined SA-105, SA-53 and SA-106B materials and set the UCS-66 curve to “A” in COMPRESS or INSPECT. After this check the option “No-UG-20(f) Exemptions” from the Codes menu >> ASME. This will allow you to check if brittle fracture will be an issue. If you need a more detailed explanation of this procedure please contact the Codeware Support Team.

For more information on this topic I recommend checking out these two papers:

Reduced Toughness Properties of Some Modern Carbon Steels Create Brittle Fracture Risk – Author: Charles (Chuck) Becht IV, PhD, PE

Reduced Toughness Properties of Some Modern Carbon Steels Create Brittle Fracture Risk

Risk of Brittle Fracture of Carbon Steel Piping During Hydrostatic Testing – Walter J. Sperko, P.E., NCPWB Consultant

Risk of Brittle Fracture of Carbon Steel Piping During Hydrostatic Testing Technical Resource