A pillar of Codeware’s success has been providing our clients with what they need to succeed. For years, we have asked our clients “where are the bottlenecks in your company”. What we learned is that as companies began running leaner, fabrication was unable to keep pace with the rate of design due to new technologies. But what about drafting? We haven’t seen any major enhancements in technology for the drafting departments since the 80’s when we introduced our Drafter program for AutoCAD. Drafters are trying to keep up with the rest of the company by putting in longer hours. The other factor was due to the fact that most companies were removing drafting departments all together. As a result, the drafting duties fell on the shoulders of the Engineer. It comes as a natural fit that Codeware found a solution for the drafting bottleneck. That solution was the Codeware Interface (CWI).

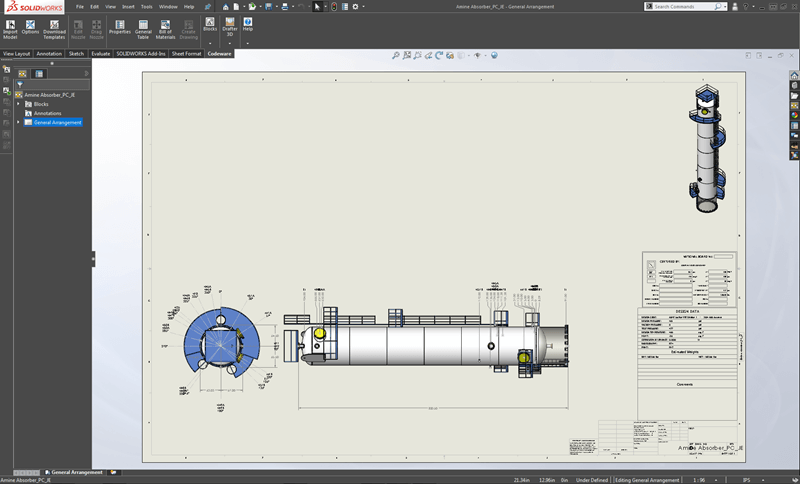

The first step for Codeware was determining the best platform(s). Years ago, COMPRESS developed the general arrangement drawing which many clients used and added to their vessel reports. This provided a quick drawing to represent their vessel and was widely accepted. One of the challenges with developing and maintaining the general arrangement drawing inside of COMPRESS was keeping up with the advanced capabilities of drawing platforms. As a result, it was decided that the Codeware Interface would truly be an interface with a 3D CAD software. After discussing the software platforms used in the industry, it was determined that SOLIDWORKS and Autodesk’s Inventor would be supported. This allows our clients the flexibility to use the software that best fit their company.

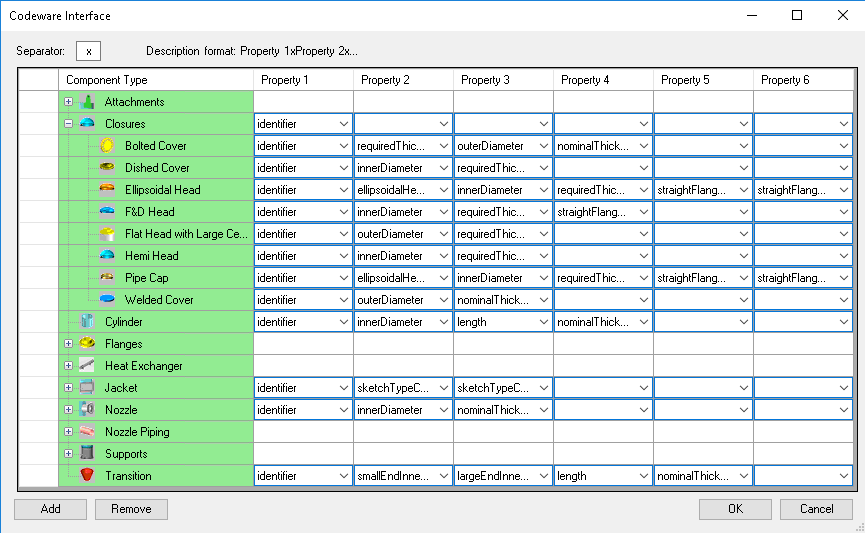

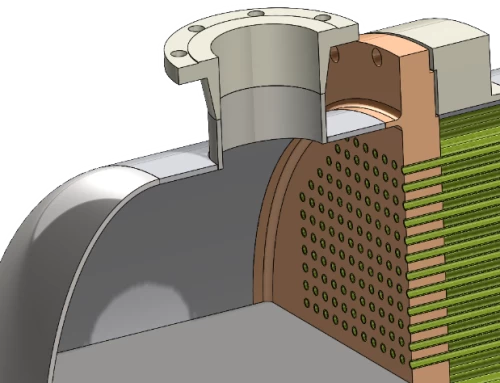

Fast forward almost 6 years and we arrive at Codeware Interface build 7800. Since the early stages, CWI has grown rapidly. Each and every build has provided enhancements to help our clients succeed. While the end goal is to provide automated drawings for fabrication, the model has required a more robust feature set so that we can take advantage of the more enhanced functionalities. From the first Nozzle Schedule tool added in build 7330, to the Assembly Configurations added to the SOLIDWORKS model in build 7510, and then the nozzle mates, CWI has always innovated. In this example, the assembly configurations provide the user more flexibility to create a customizable nozzle schedule/BOM to satisfy their company requirements. With the latest Build, CWI allows the user to make minor changes in SOLIDWORKS to nozzle placements using the built-in nozzle editor. This would not be possible without a parametric model. These are just a couple examples of how CWI will continue to innovate and increase the functionality.

This video demonstrates our nozzle edit feature. In this case, an attached ladder is interfering with a nozzle connection. The Codeware Interface allows the engineer to quickly move the nozzle to remove the interference.

Another major factor to mention here that I am sure you have heard before is the fact that all the design information from the COMPRESS or INSPECT model is brought over to the solid model. I can’t say enough how much time this will save! Think about having to enter in anywhere from 50 to 100 properties per part (like a nozzle, or head). Now do that for every part on the vessel. For a 300’ tower that is a lot of time.

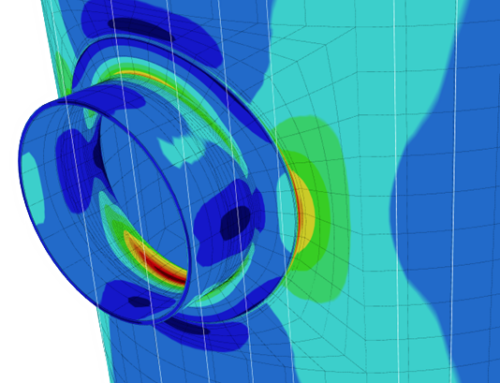

One question we tend to get is where are we going from here? Do we continue on with more drawing generation? Do we interface more closely with our other products like Shopfloor? Do we take a step into other modeling like pipe runs? The answer to all of these is yes! We strive to write software solutions for our clients so they can focus on their customer needs. With the day and age we live in, I don’t think we should be fighting with old outdated software from the 80’s.

Now couple this along with COMPRESS, Shopfloor and our Coster add-in for excel we can now break down the department walls and make it easier and more efficient for companies to focus on their customer needs.

So if you are using SOLIDWORKS or Inventor I encourage you to give it a try. We include the CWI as part of your license. So give it a try and take a step into the future of our industry. I promise you will like what you see.