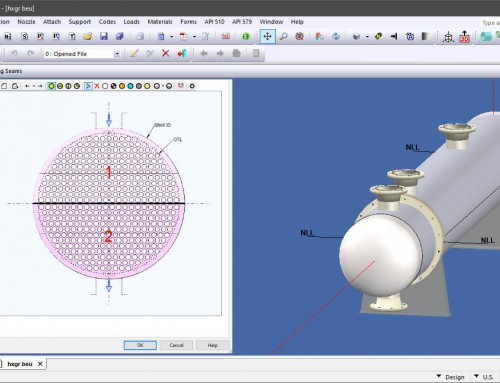

Due to process and pipe routing considerations, nozzles on pressure vessels and heat exchangers are frequently placed in non-radial orientations. These non-radial or hillside nozzle to vessel intersections create obround openings which require additional geometric calculations to meet ASME VIII BPVC rules. Put another way, the nozzle opening diameter d used for UG-37 reinforcement calculations is not fixed by the nozzle size; it changes every time a process engineer re-locates the nozzle on the equipment. COMPRESS and INSPECT use the specified nozzle orientation and location as well as the type of construction (integral or non-integral) to automatically determine the governing plane of reinforcement, F factor (see Fig. UG-37) and opening chord length (d).

Competing software products expect you to manually calculate the opening chord length and type it in for every non-radial nozzle on the vessel. COMPRESS and INSPECT save engineering hours and reduce errors by performing this tedious calculation for you.